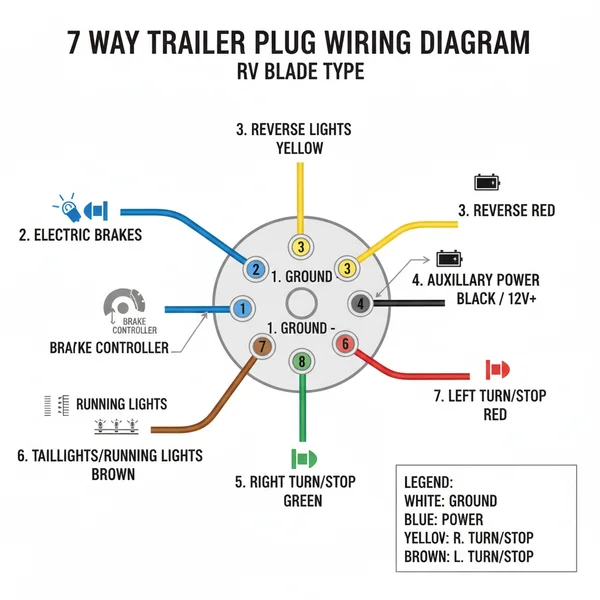

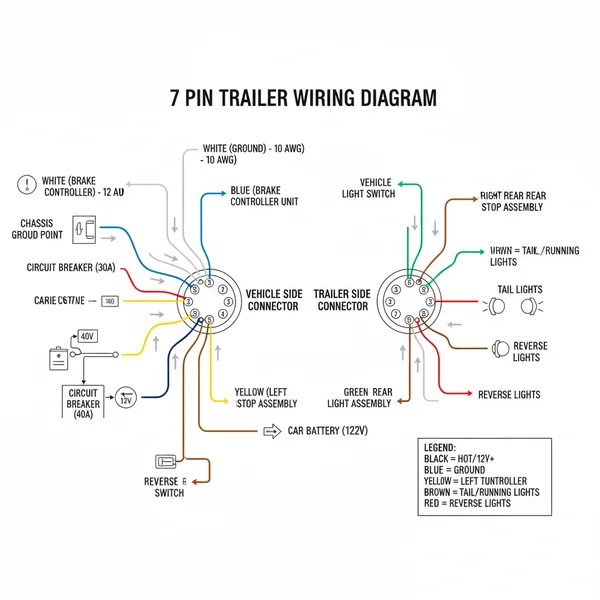

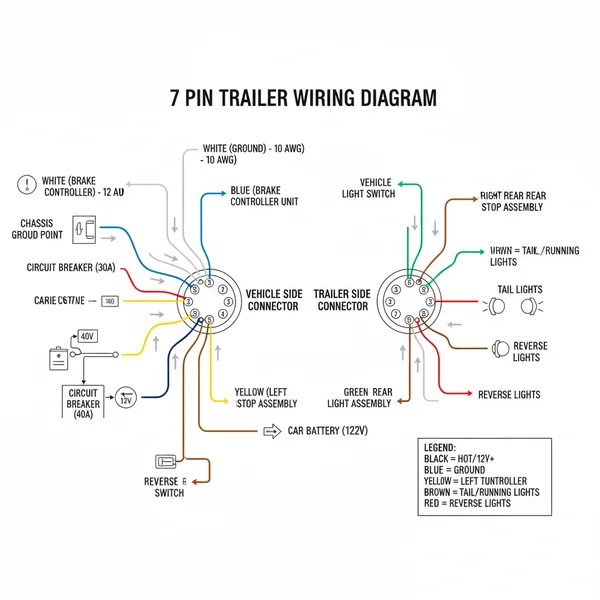

A 7 pin trailer wiring diagram illustrates how to connect your vehicle to a trailer for lights, brakes, and auxiliary power. It identifies the ground wire, the hot wire for battery charging, and signals for brakes and turn indicators, ensuring all electrical components sync perfectly for safe highway travel.

📌 Key Takeaways

- Ensures proper synchronization of trailer lights and electric brakes with the towing vehicle.

- Correctly identifying the ground wire is essential to prevent short circuits and flickering lights.

- Maintain a clean connection at the common terminal to ensure all circuits function reliably.

- Always test the hot wire and auxiliary power before departing on long trips.

- Use this diagram when installing a new hitch or troubleshooting existing trailer lighting issues.

Navigating the complexities of vehicle-to-trailer electrical connections can be a daunting task for even the most seasoned DIY enthusiast. Whether you are hauling a massive fifth-wheel camper, a horse trailer, or a heavy-duty utility flatbed, understanding the 7 pin trailer wiring diagram is essential for safety, legality, and functionality. This comprehensive guide is designed to demystify the wiring process, providing you with a clear roadmap to ensure your trailer’s lights, brakes, and auxiliary systems work in perfect harmony with your tow vehicle. By the end of this article, you will have a deep understanding of wire gauges, color codes, and the specific functions of each terminal, allowing you to troubleshoot issues or perform a complete installation with professional-grade confidence.

The 7-way trailer plug is the industry standard for trailers equipped with electric brakes and auxiliary power requirements. Unlike simpler 4-pin or 5-pin connectors that only handle basic lighting, the 7-pin configuration provides a robust interface for advanced features like internal battery charging and reverse lights. This guide will walk you through the standard RV blade configuration, which is the most common variety found on modern trucks and SUVs. We will explore the internal architecture of the plug, the importance of a solid common terminal, and how to manage high-current lines such as the hot wire for battery charging and the ground wire for circuit completion.

While color coding is standardized in the RV industry, always test your vehicle’s wires with a multimeter before making permanent connections. Some manufacturers may use proprietary colors that deviate from the standard 7 pin trailer wiring diagram.

The 7 pin trailer wiring diagram represents a circular connector with six outer pins surrounding a single center pin. Each of these positions is dedicated to a specific electrical function. In the standard RV blade configuration (the flat-blade style found on most late-model vehicles), the pins are arranged to maximize isolation between high-current and low-current circuits. The “common terminal” in this context is almost always the ground, which serves as the return path for all other circuits. Without a perfectly seated ground wire, the entire system can fail or exhibit erratic behavior, such as dim lights or flickering signals.

Inside the housing of a high-quality 7-pin plug, you will find each terminal marked with a number or a short letter code. These terminals are often secured by a brass screw, which provides excellent conductivity and corrosion resistance. When looking at the face of the vehicle-side socket (the female end), the pins are typically mapped as follows: the 12 o’clock position is the ground, the 1 o’clock position is for tail and running lights, the 3 o’clock position handles the right turn and brake signals, the 5 o’clock position is dedicated to the electric brake controller, the 7 o’clock position controls the left turn and brake signals, and the 9 o’clock position is the “hot wire” used for 12V auxiliary power or battery charging. The center pin is almost universally reserved for backup or reverse lights.

Understanding the physical layout is only half the battle; one must also understand the wire gauge requirements. Because the 7-pin system handles electric brakes and battery charging, the thickness of the wire is critical. A standard 4-pin connector might use 16-gauge wire for everything, but a 7-pin setup requires 10-gauge or 12-gauge wire for the ground and hot wire connections to handle the higher amperage without significant voltage drop. If the gauge is too thin, the wires can overheat, or the electric brakes may not receive enough current to stop the trailer effectively in an emergency.

Never substitute a thin wire for the ground or battery charge circuits. Undersized wiring can lead to a fire hazard or failure of the electric brake system, compromising your safety on the road.

To successfully install or repair your trailer wiring using a 7 pin trailer wiring diagram, follow these systematic steps. This process ensures that every connection is secure and that the circuit integrity is maintained throughout the trailer’s chassis.

- ✓ Step 1: Preparation and Tool Gathering. Before you begin, ensure you have a wire stripper, a high-quality crimping tool, a multimeter, and a container of dielectric grease. You will also need the 7-pin plug housing and the appropriate length of 7-way trailer cable.

- ✓ Step 2: Disassemble the Plug Housing. Most 7-pin plugs have a shell that slides over the wires. Slide this shell onto the cable first. If you forget this step, you will have to undo all your connections later to put the cover on.

- ✓ Step 3: Strip and Prepare the Wires. Carefully strip approximately 1/2 inch of insulation from each traveler wire. Twist the copper strands tightly to ensure they don’t splay when inserted into the terminal. For the thicker 10-gauge ground and hot wires, take extra care to ensure a clean strip.

- ✓ Step 4: Connect the Ground Wire. Start with the white wire (Ground). Locate the large brass screw at the 12 o’clock position (usually marked ‘GRD’ or ‘1’). This is the common terminal that completes the circuit for every light on the trailer. Tighten the screw firmly, ensuring the wire is fully seated.

- ✓ Step 5: Wire the Signal and Brake Lines. Following your 7 pin trailer wiring diagram, connect the remaining wires. Yellow goes to the left turn/brake terminal, green goes to the right turn/brake, and brown or green (depending on your specific cable) goes to the tail lights. The blue wire connects to the electric brake terminal.

- ✓ Step 6: Connect the Auxiliary Hot Wire and Reverse. Connect the black wire (12V Battery Charge) to the 9 o’clock position. This “hot wire” provides the voltage needed to keep your trailer’s breakaway battery charged. Finally, connect the purple wire to the center pin for reverse lights.

- ✓ Step 7: Apply Dielectric Grease and Reassemble. Before sliding the housing over the terminals, apply a generous amount of dielectric grease to each brass screw and wire end. This prevents moisture from causing oxidation and ensures long-term conductivity. Slide the shell forward and tighten the cable clamp.

- ✓ Step 8: Final Testing. Plug the trailer into the vehicle and use a helper to test the functions. Check the turn signals, brake lights, and reverse lights. Use a multimeter to verify that the 12V hot wire is receiving voltage from the vehicle’s alternator.

Reading a 7 pin trailer wiring diagram requires an understanding of how electricity “travels” through the system. In DC electrical systems, the “hot wire” refers to the positive side of the circuit, while the “neutral wire” equivalent is the ground. While “neutral” is technically an AC term, many DIYers use it to describe the return path to the common terminal. In a trailer setup, the vehicle’s chassis and the trailer’s frame often act as a secondary ground, but you should never rely on the hitch ball for electrical grounding. A dedicated white ground wire must always be used to ensure consistent voltage levels across all components.

The “traveler wire” concept is also vital to understand. This refers to the length of wire that carries the signal from the vehicle’s computer or flasher relay all the way to the rear of the trailer. Because these wires can be 20 to 30 feet long, the gauge must be sufficient to prevent “voltage drop.” If you measure 14 volts at the vehicle’s plug but only 10 volts at the trailer’s tail light, your wire gauge is likely too thin, or you have a high-resistance connection at a brass screw terminal.

If you are wiring a trailer from scratch, consider using a junction box. Instead of running all wires directly to the plug, run them to a weather-sealed box on the trailer tongue. This makes replacing a damaged 7-pin cord much easier in the future.

Even with a perfect 7 pin trailer wiring diagram, issues can arise due to the harsh environment trailers inhabit. Corrosion, vibration, and road debris are the primary enemies of trailer electronics. One of the most common issues is the “ground loop” or weak ground, where the lights behave strangely—such as the tail lights dimming when the turn signal is activated. This almost always points to a failure at the common terminal or a loose white ground wire.

Another frequent problem is the “blown fuse” on the tow vehicle. Modern trucks often have separate fuses for the trailer’s left turn, right turn, and auxiliary power. If your vehicle lights work but the trailer lights do not, check the dedicated trailer fuse box under the hood of your truck. Using a multimeter to check for voltage at the vehicle-side plug is the quickest way to determine if the problem lies with the car or the trailer.

Warning signs of failing wiring include flickering lights, a “trailer disconnected” message on your dashboard, or the electric brakes feeling “grabby” or unresponsive. If you notice smoke or the smell of burning plastic near the connector, disconnect it immediately. This indicates a short circuit, likely where a “hot wire” has rubbed through its insulation and is touching the trailer frame. If you find yourself constantly replacing fuses or if the wiring harness looks like a “rat’s nest” of electrical tape and wire nuts, it may be time to seek professional help to prevent a vehicle fire.

To ensure your wiring stands the test of time, follow these best practices for maintenance and installation:

1. Prioritize Quality Components: When buying a 7-way plug, look for one with heavy-duty brass screws and a weather-sealed housing. Cheap plastic connectors tend to crack in cold weather, allowing moisture to enter and corrode the common terminal.

2. Use Heat-Shrink Connectors: Avoid using standard “butt connectors” or electrical tape for wire splices. Heat-shrink connectors provide a waterproof seal that protects the copper traveler wire from road salt and moisture.

3. Route Wires Safely: Always run your wiring harness through protective plastic loom and secure it to the trailer frame with UV-resistant zip ties or metal clamps. Ensure the wires are not pinched by moving parts like the suspension or the hitch assembly.

4. Regular Cleaning: At least once a season, spray the plug and socket with an electrical contact cleaner. Re-apply dielectric grease to the pins to maintain a barrier against oxidation.

5. Check Your Gauge: If you are adding high-draw accessories to your trailer, such as an electric winch or an interior inverter, you may need to upgrade the 12V hot wire to an 8-gauge or 6-gauge wire, bypassing the standard 7-pin plug for those specific heavy loads.

The center pin on a 7-way plug is often left unused on small utility trailers. However, connecting this to your vehicle’s reverse circuit can be incredibly helpful for activating a trailer’s backup lights or a rear-view camera.

In conclusion, mastering the 7 pin trailer wiring diagram is an invaluable skill for anyone who tows. By understanding the relationship between the ground wire, the hot wire, and the various signal lines, you ensure that your trailer is a safe extension of your vehicle. Proper installation using the correct gauge wire and secure brass screw connections will provide years of trouble-free operation. Remember that a trailer’s electrical system is only as strong as its weakest connection—usually the ground. Keep your terminals clean, your connections tight, and your wiring protected, and you will be ready for any journey, whether it’s a quick trip to the lumber yard or a cross-country camping adventure. With this guide and a clear 7 pin trailer wiring diagram in hand, you have the knowledge to wire with precision and tow with peace of mind.

Step-by-Step Guide to Understanding the 7 Pin Trailer Wiring Diagram: Easy Towing Setup

Identify the function of each color-coded lead, such as the white ground wire and the black hot wire.

Locate the common terminal inside the trailer plug where the main electrical return path will be established.

Understand how the signals flow from the vehicle’s brake controller to the designated 7-way pin.

Connect the auxiliary 12V hot wire to ensure the trailer’s breakaway battery remains charged during transit.

Verify that the reverse lights and turn signals do not interfere with any traveler wire equivalent signal paths.

Complete the installation by sealing the connector housing and testing all functions with a multimeter or trailer tester.

Frequently Asked Questions

What is 7 pin trailer wiring diagram?

A 7 pin trailer wiring diagram is a visual guide mapping the electrical connections between a towing vehicle and a trailer. It specifies where each colored wire connects to provide power for turn signals, brake lights, electric brakes, and auxiliary battery charging, ensuring safety and legal compliance on the road.

How do you read 7 pin trailer wiring diagram?

To read the diagram, match the color-coded lines to the specific pins on the connector. Usually, the center pin is for reverse lights, while others handle the ground wire, hot wire, and signals. Understanding the pin layout from the perspective of the plug face is crucial for correct orientation.

What are the parts of 7 pin trailer wiring?

The system consists of the vehicle-side socket, the trailer-side plug, and the internal wiring harness. Key components include the heavy-gauge ground wire, the constant hot wire for 12V power, and specific pins for left/right turns, tail lights, electric brakes, and reverse lamps, often meeting at a common terminal.

Why is hot wire important?

The hot wire, typically black or red in a 7-way system, provides a continuous 12V DC power supply from the vehicle battery to the trailer. This is essential for charging the trailer’s internal breakaway battery or powering interior lights and accessories while the engine is running or parked.

What is the difference between traveler wire and neutral wire?

In DC trailer wiring, these AC terms are rarely used, but a neutral wire serves a similar function to the ground wire in completing circuits. While a traveler wire is used in 3-way home switches, trailer systems use dedicated signal wires to bridge the gap between the vehicle and trailer.

How do I use 7 pin trailer wiring diagram?

Use the diagram by stripping your trailer’s wire ends and matching them to the numbered terminals inside the plug. Secure the ground wire first, then follow the schematic to attach the signal and hot wires. Always use a circuit tester to verify that each pin receives the correct signal.