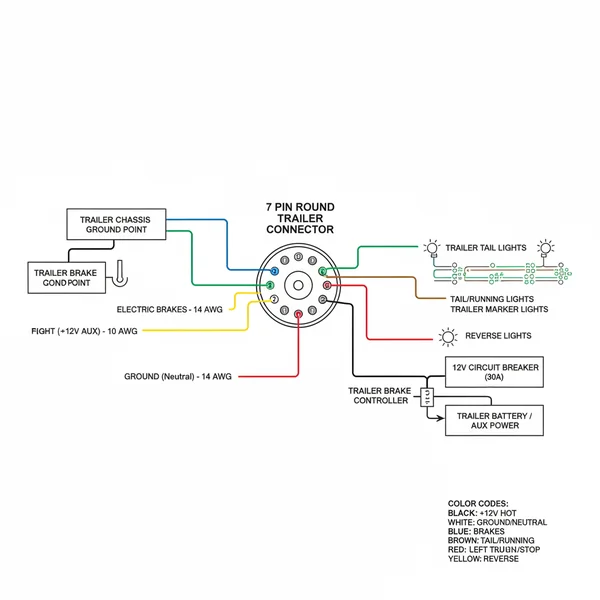

A 7 pin round trailer wiring diagram identifies the standard connections for heavy-duty towing, including lights and brakes. It maps out functions like ground, left and right turns, tail lights, auxiliary power, and electric brakes. Proper alignment ensures all signaling and braking systems communicate effectively between the vehicle and trailer.

📌 Key Takeaways

- The diagram provides a visual map for standard commercial and heavy-duty towing connections.

- The white ground wire is the most critical component to identify for circuit completion.

- Wire gauge must be sufficient to handle the high current required for electric brakes.

- Applying dielectric grease to terminals helps prevent corrosion and intermittent signal loss.

- Use this diagram when installing new plugs or repairing large trailer electrical systems.

Towing heavy-duty equipment or livestock trailers requires a robust electrical connection that goes beyond the standard 4-pin or 5-pin setups found on smaller utility trailers. If you are preparing for a long haul, having a clear and accurate 7 pin round trailer wiring diagram is the most important tool in your arsenal. This specific configuration is designed to handle higher current loads and provides dedicated circuits for electric brakes and auxiliary power. In this guide, we will explore the intricate details of the 7-way round pin connector, ensuring your vehicle and trailer communicate perfectly. You will learn the specific color codes, terminal functions, and professional installation techniques to ensure your journey is safe and your equipment remains fully operational.

There are two primary types of 7-way connectors: the “7-way RV Blade” (flat pins) and the “7-way Round Pin.” This article focuses exclusively on the round pin variety, which is commonly used for heavy-duty commercial applications, horse trailers, and agricultural equipment.

The 7-way round pin connector is a heavy-duty cylindrical plug featuring six circular pins arranged in a ring with a seventh pin located in the center. Unlike the flat-blade versions found on most modern SUVs and light trucks, the round pin connector is often favored for its mechanical durability in harsh environments. Each pin within the housing is secured by a brass screw, which acts as the clamping mechanism for the wire strands. These brass terminals are chosen for their excellent conductivity and resistance to the vibration often associated with large diesel trucks and industrial trailers.

When looking at the diagram, you will notice that each position is labeled to prevent cross-wiring. The “common terminal” or ground is the most critical component, as it provides the return path for all electrical circuits. Without a solid ground, the entire system can experience flickering lights or “ghost” signals where one light activates another. The diagram also identifies the specific locations for the tail lights, left and right turn signals, and the electric brake lead. It is important to note that while many manufacturers follow a standard color-code convention, some older trailers or custom builds may deviate. Always use the physical pin position on the diagram rather than relying solely on the wire jacket color.

[ 7 PIN ROUND TRAILER WIRING DIAGRAM ]

[GD] (Top) – White

[LT] [RT]

(Yellow) (Brown)

[S]

(Blue)

[TM] [A]

(Green) (Black)

[AUX] (Center) – Red/Purple

Note: GD=Ground, LT=Left Turn, RT=Right Turn, S=Electric Brakes, TM=Tail/Running Lights, A=Auxiliary/Battery, AUX=Center Auxiliary.

Properly interpreting the 7 pin round trailer wiring diagram requires a methodical approach to ensure that high voltage does not damage sensitive components. Before you begin the physical installation, you must gather the correct materials. For a 7-way system, the wire gauge is paramount. The ground and main power wires should typically be 10 or 12 gauge, while the signal wires (turn signals and markers) can be 14 or 16 gauge. Using a wire that is too thin can lead to overheating and significant voltage drops over the length of the trailer.

- ✓ Multimeter or 12V circuit tester

- ✓ Wire strippers and crimping tool

- ✓ Small flat-head screwdriver (for the brass screw terminals)

- ✓ Dielectric grease

- ✓ Heat shrink tubing

Step 1: Disassemble the plug housing. Most round-pin plugs have a small set screw on the side that allows the interior terminal block to slide out of the metal or plastic sleeve. Slide the sleeve onto the trailer wire bundle before you start making connections; otherwise, you will have to disconnect everything later to put the cover on.

Step 2: Strip the wires. Carefully remove about half an inch of insulation from each wire. Ensure you do not nick the copper strands. For the ground wire, which is your common terminal path, ensure the connection is particularly clean. If the copper is oxidized (turned green or dark brown), trim it back until you find shiny metal.

Step 3: Connect the ground wire. This is usually the white wire. Insert it into the terminal labeled “GD” or “1” and tighten the brass screw firmly. In trailer electronics, the ground acts similarly to a neutral wire in an AC system, providing the necessary return path to the battery.

Step 4: Connect the hot wire and auxiliary leads. The “hot wire” is generally the black wire (Auxiliary Power) which provides a constant 12V charge to the trailer battery or interior lights. Connect this to the “A” or “4” terminal. Follow this by connecting the blue wire to the “S” terminal for the electric brakes. The voltage here will vary based on the input from your brake controller.

Step 5: Wiring the signal travelers. Each “traveler wire” carries the specific signal for turning or braking. Connect the yellow wire to the “LT” (Left Turn) terminal and the brown wire to the “RT” (Right Turn) terminal. The green wire, responsible for the tail and marker lights, goes to the “TM” terminal.

Step 6: Handle the center pin. The center pin (terminal 7) is often used for backup lights or a secondary auxiliary power source. If your trailer is not equipped with reverse lights, this pin can remain empty, but it is wise to coat the empty brass screw with dielectric grease to prevent corrosion.

Step 7: Reassemble and test. Slide the housing back over the terminal block and tighten the set screw. Use your 12V tester to verify each pin. Have a partner stand behind the trailer while you cycle through the left turn, right turn, hazards, and brake pedal.

Never test trailer wiring by “sparking” wires against the frame. Modern tow vehicles have integrated computer modules that can be instantly fried by a short circuit. Always use a high-impedance multimeter or a dedicated trailer circuit tester.

Even with a perfect 7 pin round trailer wiring diagram, issues can arise due to the harsh conditions trailers endure. The most frequent problem is a “weak ground.” Because trailers often rely on the metal-to-metal contact of the hitch ball for additional grounding, a rusty hitch can cause flickering lights. If your lights dim when you hit the brakes, it is a sign that the ground wire is restricted or the wire gauge is insufficient for the load.

Another common issue is corrosion inside the plug. Water and road salt can enter the back of the housing, causing “bridging” between the brass screw terminals. This results in unintended signals, such as the tail lights blinking when you activate the turn signal. If you notice a green powdery substance inside the plug, it is time to clean the terminals with a wire brush or replace the plug entirely. If you experience a total loss of power, check the “hot wire” fuse in the tow vehicle’s engine bay fuse block; this is often a separate large-format fuse dedicated to the trailer’s auxiliary circuit.

Apply a generous amount of dielectric grease to the terminals before closing the housing. This silicone-based grease does not conduct electricity but acts as a waterproof barrier that prevents oxygen from reaching the metal, virtually eliminating terminal corrosion.

To ensure long-term reliability, always opt for tinned copper wire if you frequently tow in wet or coastal environments. Tinned copper resists the “black wire disease” (internal oxidation) much better than standard automotive wire. Additionally, when routing your wires along the trailer frame, use plastic loom and secure it with rubber-lined P-clamps rather than tight zip ties, which can cut through the insulation over time due to vibration.

Maintenance should be performed seasonally. Every six months, inspect the plug for loose brass screws. The vibrations of the road can cause these screws to back out slightly, creating a high-resistance connection that generates heat. If the plastic around a terminal looks melted, it is a clear indicator of a loose connection or an overloaded circuit.

Investing in a high-quality, metal-bodied 7-way round plug is often worth the extra cost over plastic alternatives. Metal plugs offer better impact resistance and typically feature a stronger cable strain-relief clamp, which prevents the wires from being pulled out of the terminals if the trailer is accidentally disconnected. By following the 7 pin round trailer wiring diagram precisely and maintaining your connections, you ensure that your towing experience is efficient, legal, and above all, safe. Whether you are managing the voltage for electric brakes or ensuring your traveler wire delivers a crisp turn signal, a little attention to detail goes a long way on the open road.

Step-by-Step Guide to Understanding the 7 Pin Round Trailer Wiring Diagram: Easy Connector Setup

Identify the standard color codes for each function using the schematic to prevent wiring errors.

Locate the common terminal for the ground wire to ensure the electrical circuit has a return path.

Understand how the hot wire provides auxiliary 12V power to the trailer’s battery or interior lights.

Connect the traveler wire for the left and right turn signals to their designated pins.

Verify that the neutral wire or return path is secure and not touching other active terminals.

Complete the assembly by tightening the cable clamp and testing all light and brake functions.

Frequently Asked Questions

What is 7 pin round trailer wiring diagram?

A 7 pin round trailer wiring diagram is a schematic showing how to connect a vehicle’s electrical system to a trailer. It identifies the function of each pin, such as the ground wire and various lighting circuits, ensuring that signals, brakes, and auxiliary power work correctly across the hitch connection for safety.

How do you read 7 pin round trailer wiring diagram?

To read the diagram, match the numbers on the connector face to the specified wire colors. Identify the center pin, often used for auxiliary power or a hot wire, and the surrounding pins for lights. Always look at the connector from the wire-entry side to avoid mirroring the pinout during installation.

What are the parts of 7 pin round trailer wiring?

The main parts include the heavy-duty housing, the pins or sockets, and the internal common terminal connections. Inside, you will find color-coded wires representing functions like the neutral wire for returns, brake controllers, and the traveler wire used in complex lighting configurations for directional signaling and various circuit routing tasks.

Why is ground wire important?

The ground wire is essential because it completes the electrical circuit back to the towing vehicle’s battery. Without a solid ground, the hot wire cannot deliver power effectively, leading to dim lights, flickering signals, or a complete failure of the trailer’s electric braking system during high-speed transit or emergency braking.

What is the difference between round and blade pins?

Round pins are typically used in heavy-duty or commercial applications and offer a more robust physical connection. Blade pins are standard for RVs and light trailers. While both use a hot wire for power, the pin shape and housing diameter differ, often requiring a specialized adapter for vehicle-trailer compatibility.

How do I use 7 pin round trailer wiring diagram?

Use the diagram to guide your installation by stripping each wire and securing it to the correct common terminal inside the plug. Verify each connection against the schematic to ensure signals like the traveler wire for turns aren’t crossed, which prevents dangerous miscommunication with other drivers on the road.