7 Pin Rocker Switch Wiring Diagram: Easy Installation

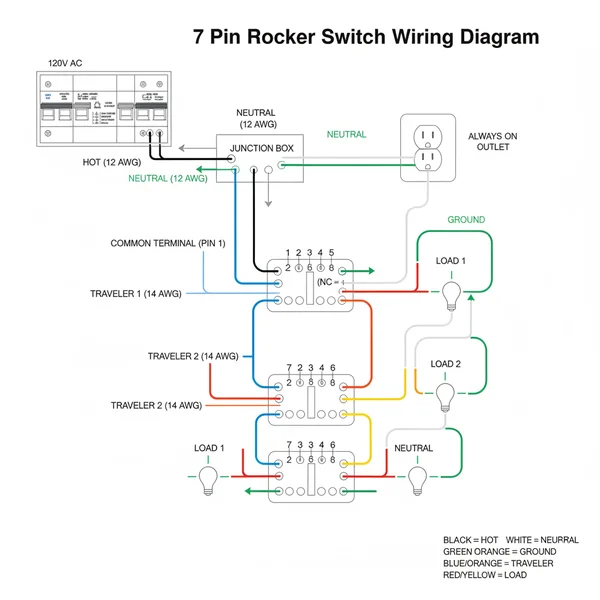

A 7 pin rocker switch wiring diagram illustrates connections for DPDT applications, often used for winches or dual-motor control. It maps the hot wire to the center common terminal, links traveler wire paths for polarity reversal, and attaches the ground wire and neutral wire to power internal LED indicators.

📌 Key Takeaways

- This diagram enables complex DPDT switching for reversing motor polarity.

- Identify the center common terminal to ensure the input power is distributed correctly.

- Always connect the ground wire to prevent short circuits and enable switch illumination.

- Use high-quality connectors to handle the high current typical in these setups.

- Refer to this diagram when installing winches, jacks, or marine electrical controls.

Understanding the intricacies of a 7 pin rocker switch wiring diagram is essential for anyone looking to manage complex electrical systems in automotive, marine, or industrial applications. Whether you are installing a high-powered winch or a dual-lighting system, the 7-pin configuration offers unparalleled control by allowing for Double Pole Double Throw (DPDT) functionality. This guide provides a detailed breakdown of the wiring architecture, ensuring you can identify the correct terminals and wire types needed for a safe installation. By the end of this article, you will have a clear roadmap for connecting your switch with confidence, minimizing the risk of short circuits or equipment damage.

A 7-pin rocker switch is typically a DPDT switch, meaning it can control two separate circuits independently or simultaneously. This is different from standard 3-pin or 5-pin switches which only handle single circuits.

Decoding the 7 Pin Rocker Switch Wiring Diagram Components

When you look at a 7 pin rocker switch wiring diagram, the layout can initially appear overwhelming due to the density of connections. However, the pins are generally organized into two vertical rows of three pins each, with a lone seventh pin dedicated to the internal lighting circuit. In a standard setup, the pins are numbered 1 through 7. Pins 1, 2, and 3 represent one pole of the switch, while pins 4, 5, and 6 represent the second pole. Pin 7 serves as the primary ground for the LED indicators found within the switch housing.

The central pins in each row (pins 2 and 5) usually act as the common terminal. This is where the primary hot wire from your power source is connected. From this central point, the current is “thrown” to either the top pins (1 and 4) or the bottom pins (3 and 6) depending on the rocker’s position. In many configurations, the top pins are used for one accessory (like high beams) while the bottom pins are used for another (like low beams or a different light bar).

Color-coding is a vital aspect of reading these diagrams accurately. While individual wire colors can vary by manufacturer, the diagram usually indicates the hot wire in red, the ground wire in black, and the traveler wire—which carries current between components—in various secondary colors like blue or yellow. You may also notice a brass screw or silver-plated terminal on some high-end switches; typically, the brass screw is reserved for the ground or neutral wire connection points to prevent corrosion and improve conductivity. Understanding these visual cues ensures that you maintain the correct voltage across the circuit without blowing fuses or overheating the switch housing.

[DIAGRAM_PLACEHOLDER – A detailed graphic showing the 7-pin layout: Pins 1 & 4 at the top, 2 & 5 in the middle (Common), 3 & 6 at the bottom, and Pin 7 for Ground. Labels indicate Hot, Traveler, and Ground paths.]

Step-by-Step Guide to Wiring Your 7 Pin Rocker Switch

Executing a successful installation requires more than just looking at a 7 pin rocker switch wiring diagram; it requires a systematic approach to electrical safety and circuit integrity. Before you begin, ensure you have the correct gauge wire for the current load. For most automotive applications, 14 or 16-gauge wire is sufficient for lighting, but high-draw accessories may require a thicker 12-gauge wire.

Always disconnect the negative terminal of your battery before starting any electrical work. This prevents accidental short circuits that could damage your vehicle’s ECU or cause a fire.

- Prepare Your Wires: Strip approximately 1/4 inch of insulation from the ends of your hot wire, neutral wire, and ground wires. Use high-quality crimp connectors or female spade terminals that match the size of the pins on your rocker switch.

- Identify the Common Terminals: Locate pins 2 and 5 on your switch. These are your input pins. Connect the main hot wire from your fused power source to these pins. If you are using both poles, you can use a jumper wire to bridge pin 2 and pin 5 so they both receive power from a single source.

- Connect the Output Loads: Pin 1 and pin 4 are typically the “On” positions when the rocker is pushed up. Connect the traveler wire from your first accessory to pin 1 and your second accessory to pin 4. If you have a second set of accessories for the “Down” position, connect them to pins 3 and 6.

- Establish the Ground: Connect pin 7 to a clean, metal part of the vehicle chassis or a common ground block. This is the ground wire specifically for the switch’s internal LEDs. Without this connection, your switch will function, but it will not light up.

- Integrate the Neutral Path: While the switch controls the hot side, your accessories still need a neutral wire path back to the battery or ground block. Ensure the negative side of your lights or motors is securely grounded.

- Final Testing: Reconnect the battery. Toggle the switch through all positions. Verify that the correct accessories activate and that the internal LED on the switch illuminates as intended according to the 7 pin rocker switch wiring diagram.

Use heat-shrink tubing over your spade connectors. This adds a layer of protection against moisture and prevents the connectors from sliding off the pins due to vehicle vibrations.

Common Issues & Troubleshooting

Even with a perfect 7 pin rocker switch wiring diagram in hand, mistakes can happen. One of the most frequent problems is “back-feeding,” where power travels through the switch incorrectly, causing all connected accessories to turn on at once. This usually occurs if the common terminal (pin 2 or 5) is accidentally swapped with an output pin (1, 3, 4, or 6). If your accessories are behaving erratically, double-check that your main hot wire is strictly connected to the middle pins.

Another common issue is a dim or non-functional LED indicator. If the switch works but the light doesn’t, pin 7 is likely not receiving a proper ground. Use a multimeter to check the voltage at the pins. If you see a significant voltage drop across the switch, it may indicate a loose connection or a wire gauge that is too thin for the load. Furthermore, if you notice the switch body becoming hot to the touch, this is a major warning sign. It suggests that the amperage being pulled through the switch exceeds its rated capacity. In such cases, you should immediately disconnect power and consider using a relay to handle the heavy lifting while the rocker switch merely triggers the relay.

Tips & Best Practices for Longevity

To ensure your wiring project lasts for years, focus on the quality of components and the environment in which they will operate. In marine or off-road environments, choose “weather-sealed” or IP66-rated rocker switches. These are designed to keep dust and water away from the internal contacts. When following your 7 pin rocker switch wiring diagram, always include an inline fuse between the power source and the switch. The fuse should be rated slightly higher than the total amperage of the connected devices but lower than the maximum rating of the switch itself.

Maintenance is also key. Periodically check the brass screw terminals or spade connectors for signs of oxidation, which can increase resistance and lead to heat buildup. If you are wiring multiple switches, using a dedicated fuse block can save you from a “nest” of wires and make future troubleshooting much simpler.

- ✓ Use a label maker to mark each traveler wire for easy identification later.

- ✓ Ensure the ground wire is connected to a paint-free surface for maximum conductivity.

- ✓ Apply dielectric grease to terminals in high-moisture environments.

- ✓ Always match the wire gauge to the circuit breaker or fuse rating.

In conclusion, mastering the 7 pin rocker switch wiring diagram allows you to take full control of your electronic accessories with professional-grade precision. By carefully mapping out your hot wire, traveler wire, and ground connections, you create a robust system capable of handling complex tasks. Always prioritize safety, use the correct tools, and refer back to the diagram whenever you are in doubt to ensure a successful and durable installation.

Frequently Asked Questions

What is a 7 pin rocker switch wiring diagram?

A 7 pin rocker switch wiring diagram is a visual map showing how to connect a Double Pole Double Throw (DPDT) switch with independent lighting. It details where the hot wire enters the common terminal and how output pins control two separate circuits or reverse motor direction while managing ground wire connections for internal LEDs.

How do you read a 7 pin rocker switch wiring diagram?

To read this diagram, start by identifying the pin numbers on the back of the switch. Locate the input source at the common terminal, follow the path of the traveler wire to the load, and ensure the neutral wire and ground wire are properly positioned to power the internal backlight indicators.

What are the parts of a 7 pin rocker switch?

The parts include the actuator, internal bridge, and seven external pins. These pins consist of power inputs at the common terminal, load outputs, and dedicated pins for the ground wire and neutral wire which complete the circuit for the switch’s built-in LED lighting systems used for visibility in low-light conditions.

Why is the common terminal important?

The common terminal is the central hub where the main hot wire connects. It acts as the bridge that transfers electrical current to the different output pins depending on the switch position. Without a correct connection at this point, the entire circuit fails to receive power or toggle between different device functions.

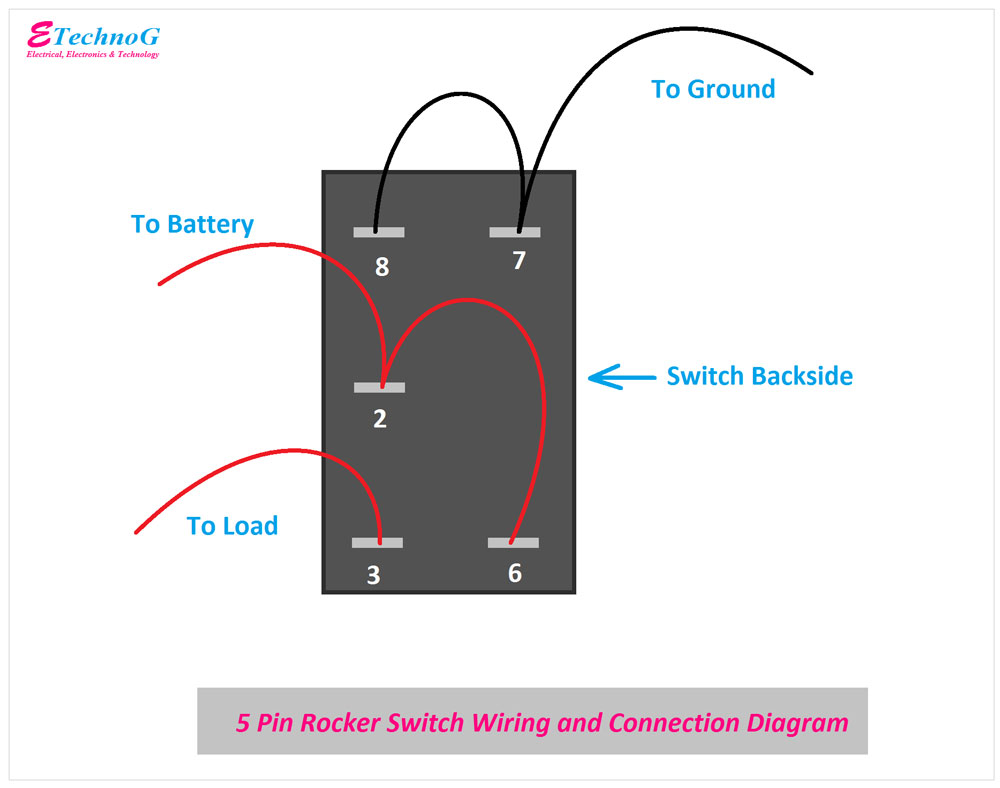

What is the difference between a 5 pin and 7 pin rocker switch?

A 5 pin switch usually manages a single circuit with simple on/off functions and one light. A 7 pin rocker switch provides DPDT functionality, allowing for more complex tasks like reversing motor polarity. It uses a traveler wire setup and extra pins to support independent lighting for both the ‘on’ and ‘off’ positions.

How do I use a 7 pin rocker switch wiring diagram?

Use the diagram as a blueprint to match physical wires to their specific pin locations. Begin by connecting the hot wire to the power source, then route the traveler wire to your device. Follow the schematic to safely ground the unit with a dedicated ground wire to ensure all functions operate correctly.