7.3 Powerstroke Fuel System Diagram: Troubleshooting & Repair

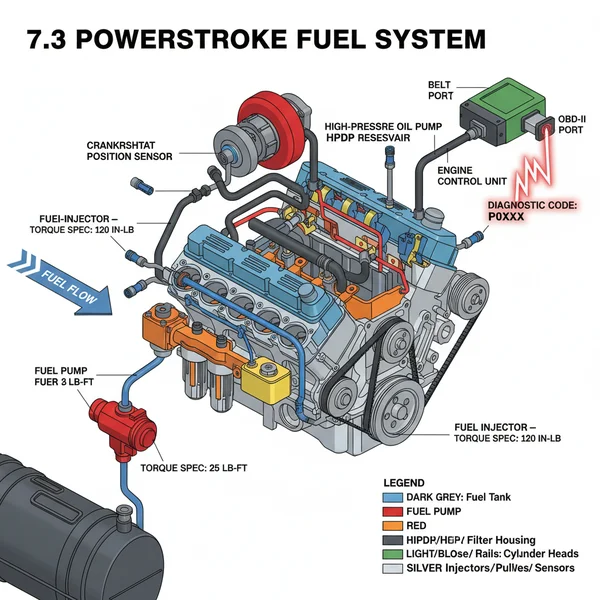

A 7.3 Powerstroke fuel system diagram maps the path from the fuel tank through the lift pump, fuel bowl, and into the injectors. It helps owners visualize the high-pressure delivery, locate the fuel pressure regulator, and identify potential leak points that might trigger a check engine light or store a specific diagnostic code.

📌 Key Takeaways

- Visually mapping the fuel path from the tank to the fuel rails

- Identifying the fuel bowl and internal heating element

- The critical role of fuel pressure in preventing injector damage

- Checking for common leak points around the fuel bowl O-rings

- Using the diagram to assist with fuel pump or regulator replacement

Understanding the 7.3 powerstroke fuel system diagram is an essential skill for any owner of the legendary Ford Super Duty or Econoline van equipped with this powerhouse engine. Known for its longevity and reliability, the 7.3L engine uses a unique Hydraulically Actuated Electronically Controlled Unit Injector (HEUI) system that differs significantly from modern common-rail setups. By studying a comprehensive diagram, you will gain the ability to pinpoint leaks, diagnose hard-start conditions, and perform vital maintenance that keeps your truck on the road. This guide provides a detailed breakdown of the fuel delivery path, from the tank to the injectors, ensuring you have the technical knowledge required for DIY repairs and performance tuning.

Detailed Breakdown of the 7.3 Powerstroke Fuel System Diagram

The 7.3 powerstroke fuel system diagram represents a dual-stage delivery process: the low-pressure fuel supply and the high-pressure oil actuation. Unlike a standard gasoline engine, the fuel itself is not under thousands of pounds of pressure until it is squeezed by high-pressure engine oil inside the injector. The diagram typically begins at the fuel tank, where a pickup assembly (often prone to clogging) draws fuel into the lines.

In the most common configurations, an electric fuel pump is mounted on the driver-side frame rail. This pump pushes fuel toward the engine bay at approximately 55 to 65 PSI. The diagram then illustrates the fuel entering the fuel filter housing, commonly known as the “fuel bowl,” located in the valley of the engine. This component is central to the system; it houses the filter element, the fuel heater (to prevent gelling), and the fuel pressure regulator (FPR).

From the fuel bowl, two lines exit and travel to the rear of the cylinder heads. These are “dead-head” lines, meaning the fuel enters the heads and stays there until consumed by the injectors. A return line exits the fuel bowl via the FPR, sending excess fuel back to the tank. The diagram also highlights the interaction with the ECU (Engine Control Unit), which monitors sensors like the ICP (Injector Control Pressure) to tell the injectors when to fire. While the engine relies on gear-driven timing rather than a traditional timing chain, the synchronization between the fuel delivery and the piston position is managed electronically via the camshaft and crankshaft position sensors.

[DIAGRAM_PLACEHOLDER: A detailed 2D schematic showing the fuel tank, frame-rail pump, fuel bowl with regulator, and lines leading into the cylinder heads. Components are color-coded: Blue for low-pressure suction, Green for pressurized fuel (55-65 PSI), and Red for the return path.]

The 7.3 Powerstroke uses a ‘dead-head’ fuel system design in its stock form. This means fuel enters the heads but does not circulate through them, which can sometimes lead to trapped air or “fuel knock” in the #8 cylinder. Many enthusiasts install a “Regulated Return” kit to turn the system into a continuous loop for more consistent pressure.

Step-by-Step Guide to Interpreting and Servicing the System

Reading a 7.3 powerstroke fuel system diagram is the first step in performing a successful repair or upgrade. To use the diagram effectively during a service, follow these steps to ensure you are covering all critical points of the fuel delivery path.

Step 1: Locate the Fuel Pickup and Tank Components

Start at the back of the diagram. The fuel pickup inside the tank contains two small mesh screens that can become clogged with debris or “algae” over time. If your truck stalls at a quarter tank, the pickup foot may have broken off. Verify that the suction line is clear before moving to the pump.

Step 2: Inspect the Frame-Rail Pump

Moving forward along the driver-side frame rail, you will find the electric fuel pump. This is a common failure point. When the key is turned to the “On” position, you should hear a distinct hum for about 20 seconds. If the pump is silent or making a grinding noise, it is likely failing. Always check the electrical connections for corrosion, as road salt can degrade the wiring.

Step 3: Access the Fuel Bowl and Filter

In the engine valley, the fuel bowl is the most accessible part of the system. Open the yellow drain valve to empty the bowl before unscrewing the cap. When replacing the filter, always inspect the “Stand Pipe” in the center for damage. This is also the time to check the fuel heater element at the bottom of the bowl. If the heater shorts out, it will often blow the fuse that powers the PCM, resulting in a “no start” condition and no communication with your OBD-II scanner.

Step 4: Check the Fuel Pressure Regulator (FPR)

On the side of the fuel bowl is the FPR. This small housing contains a spring and a plunger that maintains the 55-65 PSI required for the injectors. Over time, the spring can weaken, leading to low fuel pressure and loss of power. Some DIYers perform the “blue spring” mod or shim the spring to restore pressure.

Step 5: Monitor the High-Pressure Oil Interaction

While not strictly “fuel,” the HEUI system requires high-pressure oil to fire the injectors. Use the diagram to locate the High-Pressure Oil Pump (HPOP) in the front of the valley. Ensure your oil levels are topped off, as low oil will cause the fuel injectors to stop firing. Check the coolant flow in the nearby oil cooler to ensure there is no cross-contamination between the oil and cooling systems.

Step 6: Reassembly and Torque Specs

When reassembling the fuel bowl or replacing lines, following the correct torque spec is vital to prevent leaks in the high-vibration environment of a diesel engine. Fuel bowl mounting bolts should generally be torqued to 15-20 lb-ft. Ensure that all banjo bolts and compression fittings are snug but not over-tightened, as the aluminum threads in the heads can strip easily.

Always wear eye protection and gloves when working on the fuel system. Diesel fuel is under pressure and can cause skin penetration injuries. Ensure the engine is cool and the batteries are disconnected before performing any work near the accessory belt or electrical sensors.

Common Issues and Troubleshooting

The 7.3 Powerstroke is a workhorse, but it is not immune to fuel-related gremlins. One of the most common issues is a “crank, no-start” condition. Using your 7.3 powerstroke fuel system diagram, you can narrow this down to a few culprits. First, check if the check engine light illuminates when the key is on; if it doesn’t, the PCM (ECU) may not be getting power, often due to a shorted fuel heater.

If the engine is running poorly, use an OBD-II scan tool to pull a diagnostic code. Common codes like P1211 or P1212 indicate that the injection control pressure is not matching what the ECU expects. This could be a fuel delivery issue or a failing IPR (Injection Pressure Regulator) valve.

Another frequent problem is fuel leaking into the engine “valley.” This is usually caused by failing O-rings on the fuel bowl drain valve or the fuel lines themselves. Because the fuel bowl sits in the center of the engine, leaks here will run down the back of the block, often being mistaken for a rear main seal leak. Following the diagram will help you trace the leak upward to its true source.

Tips and Best Practices for Maintenance

Maintaining the 7.3 fuel system is relatively straightforward if you stay proactive. Following these pro tips will extend the life of your injectors and pump significantly.

Always use Motorcraft or high-quality Racor fuel filters. The 7.3 injectors have very tight tolerances, and cheap “off-brand” filters often fail to trap smaller particulates or lack the proper water-seperating membrane, leading to premature injector failure.

- ✓ Drain the Water Separator: Do this at every oil change. Water is the enemy of diesel injectors.

- ✓ Monitor Fuel Pressure: Installing a permanent fuel pressure gauge is the best way to catch a failing pump before it leaves you stranded.

- ✓ Check the Accessory Belt: While checking fuel lines, ensure your accessory belt is in good condition, as it drives the alternator that powers the IDM (Injector Driver Module).

- ✓ Use Fuel Additives: Modern Ultra-Low Sulfur Diesel (ULSD) lacks the lubricity that older 7.3 injectors were designed for. Adding a lubricity improver can quieten the “cackle” and protect the internal parts.

In conclusion, mastering the 7.3 powerstroke fuel system diagram is the key to maintaining one of the most reliable diesel engines ever built. Whether you are chasing a diagnostic code with your OBD-II scanner, replacing a leaking O-ring, or simply performing routine filter changes, having a visual and conceptual map of the system is invaluable. By understanding how the ECU manages the flow of fuel and high-pressure oil, and by keeping an eye on critical components like the fuel bowl and frame-rail pump, you ensure that your Powerstroke remains a dependable partner for years to come. Professional-level maintenance starts with a clear understanding of the diagram, allowing you to approach every repair with confidence and precision.

Frequently Asked Questions

What is 7.3 powerstroke fuel system diagram?

A 7.3 Powerstroke fuel system diagram is a visual map illustrating how diesel travels from the tank to the fuel injectors. It highlights critical components like the electric lift pump, fuel bowl, and pressure regulator, allowing mechanics to trace flow paths and identify where pressure drops or leaks may occur during engine operation.

How do you read 7.3 powerstroke fuel system diagram?

Reading the diagram involves following the fuel flow lines, usually starting at the fuel tank. Look for symbols representing the lift pump, filter housing, and fuel rails. Arrows indicate the direction of flow, while labels help you differentiate between suction lines, high-pressure delivery lines, and the return-to-tank circuit.

What are the parts of 7.3 powerstroke fuel system?

The system consists of the fuel tank, pick-up tube, electric frame-mounted pump, fuel filter bowl assembly, and high-pressure fuel rails within the cylinder heads. It also includes the fuel pressure regulator and the injectors themselves, which are electronically controlled by the vehicle’s computer system to ensure precise combustion timing and power.

Why is ECU important?

The ECU is critical because it controls the fuel injector solenoids based on sensor data. By monitoring variables like oil temperature and throttle position, the ECU determines exactly when and how much fuel to inject. If the ECU detects an electrical fault, it will trigger a check engine light and store a diagnostic code.

What is the difference between early and late 99 systems?

The primary difference lies in the pump and fuel bowl design. Early 1999 models utilized a slightly different mechanical setup, while late 1999 and newer models transitioned to a more efficient electric pump system. Understanding these variations is essential for ensuring you use the correct torque spec when tightening fuel line fittings.

How do I use 7.3 powerstroke fuel system diagram?

Use the diagram to isolate specific failure points when you encounter performance issues. For instance, if you see an OBD-II code related to fuel delivery, the diagram helps you locate the sensors and mechanical components involved. This visual guide simplifies the process of checking for air leaks or clogged filters.