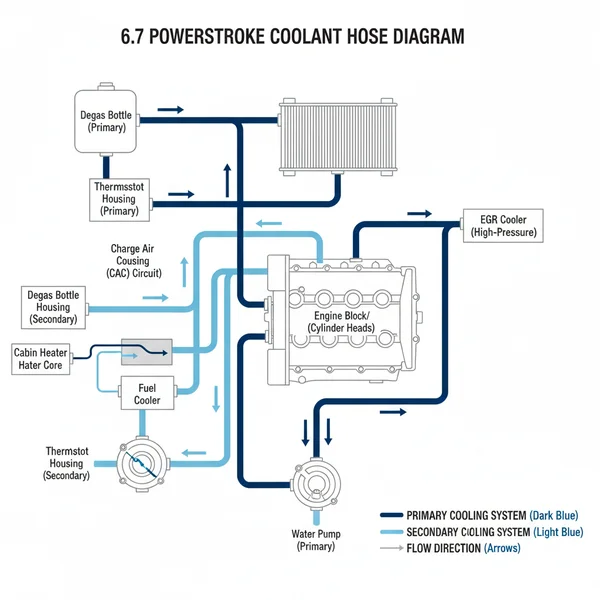

6.7 Powerstroke Coolant Hose Diagram: Full System Layout

A 6.7 Powerstroke coolant hose diagram illustrates the dual-cooling system structure, consisting of the primary engine cooling and secondary charge air cooling circuits. This layout maps every component, including the radiator, EGR cooler, and degas bottle, allowing owners to identify leaks, verify hose configuration, and maintain optimal thermal performance.

📌 Key Takeaways

- Visualizing the dual-cooling circuit layout

- Identifying the secondary cooling system pump

- Never opening the degas bottle while hot

- Using the diagram to trace specific leak points

- Troubleshooting overheating or EGR issues

Understanding the intricate cooling architecture of a 6.7L Powerstroke diesel engine is critical for any truck owner or professional mechanic. Because these engines utilize a sophisticated dual-cooling system, having a reliable 6.7 powerstroke coolant hose diagram is essential for identifying specific leak points, replacing worn components, and ensuring peak engine performance. This comprehensive guide provides a detailed breakdown of the system layout, explaining the configuration of both primary and secondary cooling loops. You will learn how to identify specific hoses, understand their structural placement within the engine bay, and gain the technical knowledge required to perform maintenance or repairs with precision.

Understanding the 6.7 Powerstroke Coolant Hose Layout

The 6.7 Powerstroke engine is unique because it features two separate cooling systems: the primary cooling system and the secondary cooling system. Each system has its own radiator, water pump, and set of hoses, which can make the layout appear daunting at first glance. The 6.7 powerstroke coolant hose diagram visualizes how these two systems interact while remaining physically distinct.

The primary cooling system is responsible for regulating the temperature of the engine block and cylinder heads. Its configuration includes heavy-duty EPDM rubber hoses that connect the large primary radiator to the engine-driven water pump, the oil cooler, and the EGR cooler. This system operates at a higher temperature than the secondary loop and uses the largest diameter hoses in the engine bay.

In contrast, the secondary cooling system manages the temperature for the charge air cooler (intercooler), the fuel cooler, and the transmission oil cooler. The structure of this loop involves a complex series of smaller-diameter hoses and a dedicated secondary water pump located on the front of the engine. A key component in this layout is the degas bottle (coolant reservoir), which often features a “Y-pipe” or venturi tee configuration. This specific component is a frequent point of interest in diagrams because it is prone to cracking and leaking over time.

[DIAGRAM_PLACEHOLDER – A detailed schematic illustrating the Primary Cooling Loop (Radiator, EGR Cooler, Engine Block) and the Secondary Cooling Loop (Intercooler, Fuel Cooler, Transmission Cooler) with color-coded flow paths.]

The diagram identifies the color-coding typically used in technical manuals: blue usually represents the cooler return lines, while red indicates the high-temperature supply lines. By studying the component arrangement, you can see how the hoses route around the fan shroud and over the top of the engine, often secured by plastic retaining clips that prevent vibration-induced wear.

Most 6.7 Powerstroke models utilize “Quick-Connect” style fittings on several major hoses. These fittings use an internal O-ring and a metal spring clip rather than a traditional worm-gear clamp. Always inspect the internal O-ring for flat spots or tears during any hose service.

Step-by-Step Guide: How to Use the 6.7 Powerstroke Coolant Hose Diagram

Interpreting a complex system diagram requires a systematic approach. Whether you are performing a routine flush or replacing a burst radiator hose, follow these steps to use the 6.7 powerstroke coolant hose diagram effectively and safely.

- 1. Identify the Target Loop: Before looking at the diagram, determine if you are working on the primary or secondary system. The primary system uses the larger degas bottle cap (rated at a higher PSI), while the secondary system uses the smaller cap. Locate the corresponding section on your diagram to avoid confusion.

- 2. Locate the Water Pump Reference: Every cooling diagram uses the water pump as a central anchor point. On the 6.7 Powerstroke, the primary pump is centrally located behind the fan, while the secondary pump is mounted higher and to the side. Use these as your starting points to trace the flow.

- 3. Trace the Flow Direction: Follow the arrows on the diagram to understand which hoses are “supply” (hot) and which are “return” (cool). This is vital if you are installing a bypass or testing for blockages. Hot coolant flows from the engine/components toward the radiator.

- 4. Prepare Your Tools: Based on the diagram’s hose types, gather your tools. You will likely need a set of constant tension hose clamp pliers for the spring clamps and a small flat-head screwdriver or a pick tool to release the metal clips on the quick-connect fittings.

- 5. Drain and Isolate: Use the diagram to find the lowest point in the specific loop you are servicing. For the primary system, this is usually the petcock on the bottom of the driver-side radiator. Drain the coolant into a clean container if you plan to reuse it, or dispose of it according to local regulations.

- 6. Disconnect and Inspect: Carefully remove the hoses as indicated by the layout. Check the plastic “Y” connectors and the “T” junctions shown on the diagram. These are often made of composite plastic that becomes brittle over time due to heat cycles.

- 7. Install and Verify: When installing the new hose, ensure the orientation matches the diagram exactly. For quick-connects, you should hear a distinct “click” when the hose is seated. Tug on the hose to ensure it is locked in place before refilling.

- 8. Vacuum Fill the System: The 6.7 Powerstroke system is notorious for trapping air pockets (airlocks). It is highly recommended to use a vacuum coolant refiller tool, which uses compressed air to pull a vacuum on the entire system, then sucks the coolant in, ensuring no air remains in the heater core or EGR cooler.

Never open the degas bottle caps while the engine is hot. The systems are under significant pressure, and opening them can cause a violent eruption of boiling coolant, leading to severe burns.

Common Issues & Troubleshooting

Even with a high-quality 6.7 powerstroke coolant hose diagram, troubleshooting can be tricky. One of the most frequent problems is a leak at the primary radiator hose quick-connect fitting. Over time, the internal O-ring degrades, or debris prevents a proper seal. If you notice a small puddle of orange or yellow coolant on the driver’s side, this fitting is the first place to check.

Another common failure point is the plastic “Y-pipe” that merges the coolant lines near the top of the engine. These often develop hairline cracks that only leak when the system is under full operating pressure. If your coolant level is dropping but you see no visible drips, use the diagram to locate the EGR cooler hoses. A failure in the EGR cooler can allow coolant to leak internally into the exhaust stream, often resulting in white smoke from the tailpipe and a sweet smell in the exhaust.

Warning signs to watch for include:

- ✓ Fluctuating temperature gauge readings.

- ✓ Dried white crusty residue (coolant salts) around hose connections.

- ✓ Soft or “spongy” hoses that collapse when the engine cools down.

If you experience a sudden overheating event, refer to your diagram to check the belt-driven water pump and the secondary electric pump. If the secondary pump fails, your intercooler will not function properly, leading to high intake air temperatures and reduced engine power.

Tips & Best Practices for Cooling System Maintenance

Maintaining the complex hose configuration of the 6.7 Powerstroke requires a proactive approach. Using the correct components and fluids is the most effective way to prevent long-term damage to the engine structure.

When replacing hoses, always opt for OEM Motorcraft parts. The 6.7 Powerstroke is sensitive to hose dimensions and fitting tolerances. Aftermarket hoses often lack the precise molding required to clear the tight spaces in the engine bay, leading to rubbing and premature failure.

To save money and time in the long run, consider replacing all major hoses simultaneously if your truck has exceeded 150,000 miles. Rubber components naturally degrade from the inside out due to the electrochemical reactions within the coolant. If one hose has failed, the others in that loop are likely in a similar condition.

Furthermore, always verify your coolant type. Newer models often transitioned from Motorcraft Orange to Motorcraft Yellow coolant. Consult your owner’s manual or a Technical Service Bulletin (TSB) to ensure compatibility. Mixing incompatible coolants can lead to “sludging,” which clogs the narrow passages in the EGR cooler and radiator, eventually causing catastrophic engine failure.

Finally, keep your 6.7 powerstroke coolant hose diagram handy during every oil change. Take five minutes to trace the lines and look for any signs of rubbing against the frame or other engine components. Ensuring that all plastic retaining clips are properly seated will prevent vibration from sawing through a hose, saving you from an expensive roadside breakdown. By following these best practices and understanding the system’s layout, you can ensure your Powerstroke remains reliable for hundreds of thousands of miles.

Frequently Asked Questions

What is 6.7 Powerstroke coolant hose diagram?

A 6.7 Powerstroke coolant hose diagram is a visual map showing the routing and connections of hoses within the engine’s cooling system. It illustrates the dual-cooling configuration, highlighting how the primary and secondary circuits operate independently to regulate temperatures for the engine block, transmission, and intercooler.

How do you read 6.7 Powerstroke coolant hose diagram?

To read the diagram, start by identifying the primary and secondary radiators. Follow the color-coded lines or arrows representing flow direction through each component. Recognize the structure by locating major junctions like the water pump, thermostat housing, and EGR cooler to understand how coolant circulates through the layout.

What are the parts of 6.7 Powerstroke?

The main parts include the primary and secondary radiators, water pumps, thermostats, and the degas bottle. The system structure also features an EGR cooler, oil cooler, and heater core. Numerous hoses and quick-connect fittings link these components together, forming the comprehensive cooling configuration necessary for diesel performance.

Why is secondary cooling pump important?

The secondary cooling pump is a vital component that manages temperatures for the charge air cooler, transmission oil cooler, and fuel cooler. This independent system configuration ensures that intake air remains dense and cool, which is essential for maintaining power output and preventing overheating in sensitive auxiliary engine components.

What is the difference between primary and secondary circuits?

The primary circuit focuses on cooling the engine block, cylinder heads, and turbocharger. In contrast, the secondary circuit features a separate layout designed for lower-temperature tasks like cooling the intercooler and transmission. Each circuit has its own radiator, pump, and thermostat to maintain specific temperature requirements effectively.

How do I use 6.7 Powerstroke coolant hose diagram?

Use the diagram to identify specific hose locations when searching for leaks or performing repairs. By understanding the system configuration, you can verify that all hoses are correctly routed and secured. It serves as a vital reference for bleeding air from the lines after a coolant flush or component replacement.