6.7 Cummins Exhaust System Diagram: Identifying Components

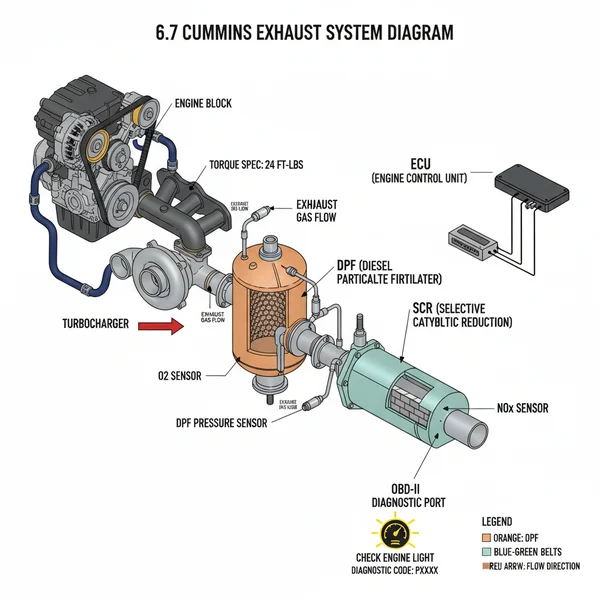

A 6.7 Cummins exhaust system diagram illustrates the path from the turbocharger through the aftertreatment system, including the DOC, DPF, and SCR. It helps technicians identify sensor locations for the ECU to monitor emissions. Understanding these connections is essential for resolving OBD-II diagnostic codes and maintaining optimal diesel engine performance.

📌 Key Takeaways

- Identifies the flow of exhaust gases through the aftertreatment assembly

- Helps locate critical sensors like NOx and pressure sensors

- Essential for diagnosing emission-related performance drops

- Provides visual context for applying correct torque specs

- Used when a check engine light indicates a filter or sensor failure

Understanding the layout of a modern heavy-duty diesel engine can be a daunting task, especially when dealing with the complex emissions hardware found on the 6.7 Cummins. Navigating a 6.7 Cummins exhaust system diagram is the first step for any truck owner or technician looking to perform maintenance, diagnose a loss in power, or install performance upgrades. This visual guide serves as a roadmap through the intricate network of piping, sensors, and filtration units that manage heat and pollutants. By studying the 6.7 Cummins exhaust system diagram, you will gain the knowledge necessary to identify critical components like the Diesel Particulate Filter (DPF) and the Selective Catalytic Reduction (SCR) unit, ultimately allowing you to maintain your vehicle’s longevity and peak performance.

Understanding the 6.7 Cummins Exhaust System Diagram Components

A 6.7 Cummins exhaust system diagram is more than just a map of pipes; it is a schematic of a high-tech laboratory that lives under your truck. The system begins at the exhaust manifold, where spent gases are collected from the cylinders. From there, the flow is directed into the turbocharger. In the context of a 6.7 Cummins exhaust system diagram, you will notice that the turbocharger acts as the gateway between the engine block and the aftertreatment assembly.

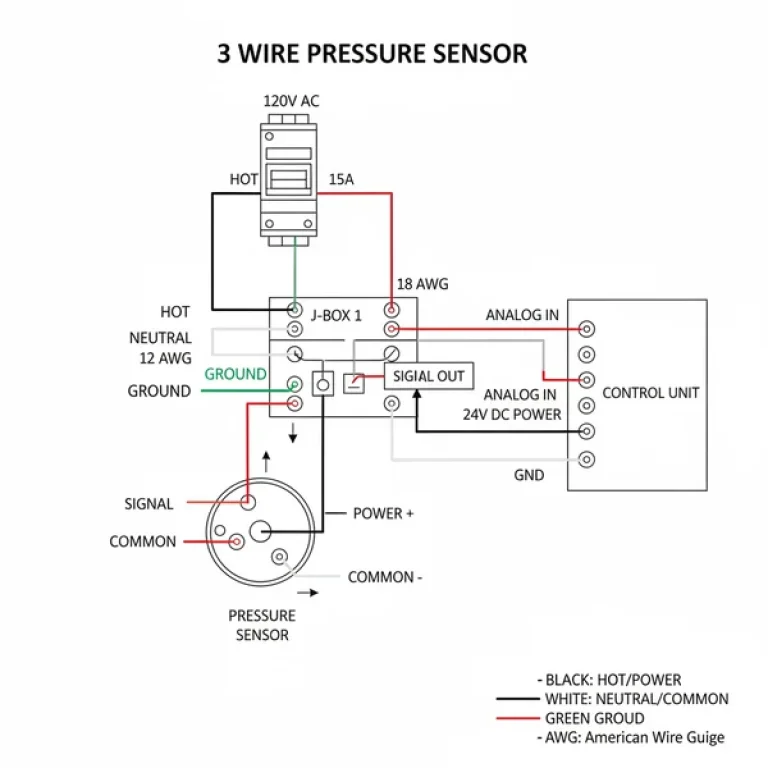

The aftertreatment section is where the complexity truly resides. First in line is the Diesel Oxidation Catalyst (DOC). This component is designed to break down carbon monoxide and hydrocarbons. Following the DOC is the Diesel Particulate Filter (DPF), which is a physical trap for soot. The diagram will show pressure sensors located both before and after the DPF; these are crucial for the ECU to monitor “restriction” or soot buildup. If these sensors detect too much backpressure, the ECU triggers a regeneration cycle to burn off the trapped matter.

Further down the stream, the 6.7 Cummins exhaust system diagram illustrates the Decomposition Tube. This is where Diesel Exhaust Fluid (DEF) is injected into the exhaust stream. The fluid mixes with the gases before entering the Selective Catalytic Reduction (SCR) catalyst. The SCR is responsible for reducing Nitrogen Oxides (NOx) into harmless nitrogen and water vapor. Finally, the cleaned exhaust passes through the muffler (in some configurations) and out through the tailpipe. Each of these components is connected by heavy-duty V-band clamps or bolted flanges, each requiring a specific torque spec to ensure a leak-free seal that prevents a check engine light from illuminating on your dashboard.

[DIAGRAM_PLACEHOLDER: A detailed technical illustration showing the 6.7 Cummins exhaust flow from the turbocharger, through the DOC, DPF, and SCR units, highlighting sensor locations for NOx, temperature, and pressure.]

The 6.7 Cummins exhaust system is a “closed-loop” system. This means the ECU constantly monitors the output via NOx sensors and adjusts the engine’s parameters and DEF injection rates in real-time to meet strict environmental standards.

Step-By-Step Guide to Interpreting and Servicing the System

Reading a 6.7 Cummins exhaust system diagram effectively requires an understanding of how the ECU (Engine Control Unit) interacts with physical hardware. If you are using the diagram to perform a repair or an inspection, follow these steps to ensure accuracy and safety.

- ✓ Step 1: Identify the Flow Direction – Always start at the turbocharger outlet (the “downpipe”). Following the 6.7 Cummins exhaust system diagram in the direction of gas flow ensures you don’t confuse the DOC with the SCR, as they often look similar from the exterior.

- ✓ Step 2: Locate the Sensors – Use the diagram to find the four main types of sensors: EGT (Exhaust Gas Temperature) sensors, NOx sensors, pressure differential sensors, and the DEF injector nozzle. Knowing their exact location is vital when a diagnostic code points to a specific bank or stage of the aftertreatment.

- ✓ Step 3: Perform an OBD-II Scan – Before touching any hardware, connect an OBD-II scanner to the vehicle. Compare the live data readings for exhaust backpressure and NOx levels against the expected values shown in your technical manual or diagram specifications.

- ✓ Step 4: Prepare the Hardware – Exhaust components are subject to extreme heat cycles, leading to rusted or “frozen” bolts. Use a high-quality penetrating oil on all V-band clamps and sensor threads several hours before attempting removal.

- ✓ Step 5: Verify Gasket Integrity – When reassembling parts based on the 6.7 Cummins exhaust system diagram, always use new gaskets and seals. Even a microscopic leak before the SCR can cause a diagnostic code and force the engine into “limp mode.”

- ✓ Step 6: Apply Correct Torque Specs – Use a calibrated torque wrench for all fasteners. V-band clamps generally require specific tensioning to allow for thermal expansion without leaking. Over-tightening can deform the flange, while under-tightening leads to soot leaks.

When working under the vehicle, safety is paramount. The aftertreatment components, particularly the DPF, are incredibly heavy and can retain searing heat long after the engine has been turned off. Always use rated jack stands and allow the system at least two hours to cool down before beginning work.

Never attempt to service the exhaust system while the engine is in a regeneration cycle. Temperatures inside the DPF can exceed 1,100 degrees Fahrenheit, posing a severe burn risk and fire hazard.

Common Issues and Troubleshooting

The 6.7 Cummins is a legendary powerplant, but its exhaust system is often the source of a check engine light. One of the most frequent problems is DPF clogging. This usually occurs when the truck is driven for short distances, preventing the exhaust from reaching the temperatures necessary for a natural passive regeneration. By referencing your 6.7 Cummins exhaust system diagram, you can locate the differential pressure sensor tubes. If these tubes are cracked or clogged with soot, the ECU will receive incorrect data, potentially failing to trigger a needed regen.

Another common issue involves the SCR system and DEF quality. If the DEF injector becomes crystallized or the NOx sensors fail, the vehicle may display a diagnostic code such as P20EE (SCR NOx Catalyst Efficiency Below Threshold). The diagram helps you pinpoint exactly which sensor is “upstream” and which is “downstream,” allowing for targeted replacement rather than expensive guesswork. Furthermore, keep an eye on the EGR (Exhaust Gas Recirculation) cooler. While technically part of the intake and cooling circuit, it interfaces directly with the exhaust manifold. A leak here can lead to excessive white smoke and a loss of coolant flow, which mimics exhaust failure symptoms.

If you encounter a “DPF Full” message, try driving the truck at highway speeds for 30 minutes. This provides the sustained heat and airflow required to complete a mobile regeneration cycle without needing a dealership service tool.

Maintenance Tips and Best Practices

To keep your 6.7 Cummins exhaust system functioning according to the original 6.7 Cummins exhaust system diagram specifications, regular maintenance is required beyond just the exhaust pipe itself. For instance, maintaining proper coolant flow is essential because the EGR cooler relies on the engine’s cooling system to lower the temperature of recirculated gases. If the cooling system is neglected, the EGR cooler can crack, sending coolant into the exhaust stream and ruining the expensive DPF and DOC filters.

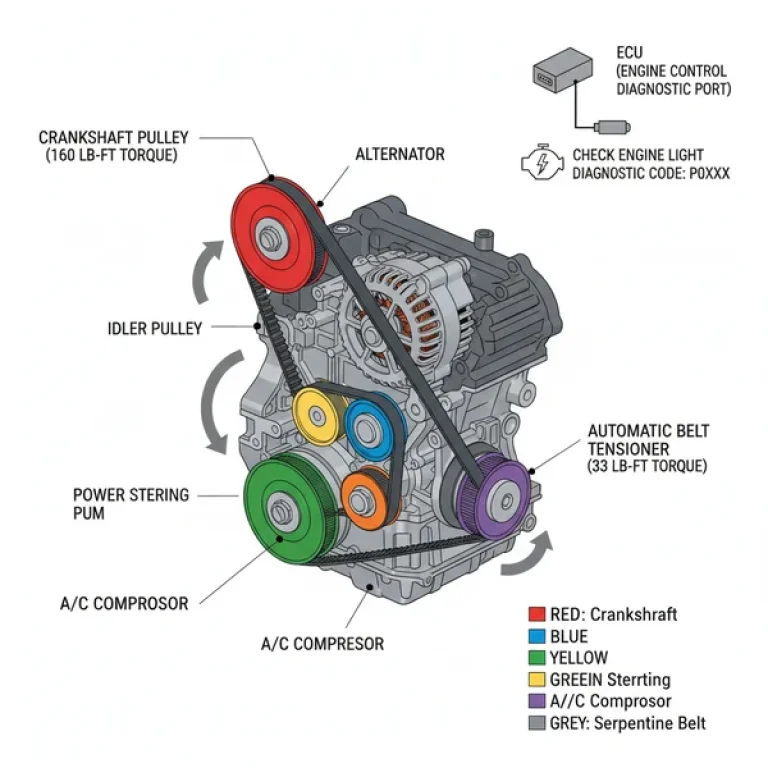

Additionally, pay attention to the front of the engine. While a timing chain isn’t a concern on the gear-driven Cummins, the accessory belt must be in good condition. The accessory belt drives the water pump; if the pump fails, the engine overheats, and the resulting high exhaust temperatures can melt the internal substrates of your catalytic converters.

- ✓ Use High-Quality Fuel: Low-quality diesel with high sulfur content can “poison” the catalysts shown in your 6.7 Cummins exhaust system diagram, leading to permanent damage.

- ✓ Monitor DEF Fluid: Only use fresh Diesel Exhaust Fluid. DEF has a shelf life, and contaminated fluid will quickly clog the injector and the SCR brick.

- ✓ Check for Soot Leaks: Periodically inspect the joints and clamps identified in your diagram. Black “soot trails” near a flange indicate a leak that could be skewing your sensor readings.

In conclusion, mastering the 6.7 Cummins exhaust system diagram is the most effective way to ensure your truck remains reliable and compliant with emissions standards. By understanding how each component—from the turbocharger to the SCR—works in tandem, you can diagnose issues faster, perform repairs more accurately, and avoid the high costs of “parts-cannon” troubleshooting. Whether you are addressing a stubborn diagnostic code or simply performing routine checks, keep your diagram handy and your sensors clean for the best driving experience.

Step-by-Step Guide to Understanding the 6.7 Cummins Exhaust System Diagram: Identifying Components

Identify the flow direction starting from the turbocharger downpipe toward the rear of the vehicle.

Locate the Diesel Oxidation Catalyst (DOC) and Diesel Particulate Filter (DPF) sections on the diagram.

Understand how the NOx and pressure sensors interface with the ECU for emissions monitoring.

Connect the symptoms of a check engine light to the specific component shown in the schematic.

Verify that every flange and sensor installation meets the manufacturer-recommended torque spec to prevent leaks.

Complete the diagnostic process by clearing the OBD-II diagnostic code after verifying the physical repair.

Frequently Asked Questions

What is a 6.7 Cummins exhaust system diagram?

A 6.7 Cummins exhaust system diagram is a visual representation of the path exhaust gases take from the manifold to the tailpipe. It highlights key aftertreatment components like the Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) system. This map is vital for identifying sensor placements and flow directions.

How do you read a 6.7 Cummins exhaust system diagram?

To read this diagram, start at the turbocharger outlet and follow the arrows downstream. Identify symbols representing the Diesel Oxidation Catalyst, DPF, and SCR. Note the electrical connections leading to the ECU, which signify sensor locations. Dotted lines or labels usually indicate the flow of Diesel Exhaust Fluid (DEF).

What are the parts of a 6.7 Cummins exhaust system?

The primary parts include the turbo downpipe, Diesel Oxidation Catalyst (DOC), and the Diesel Particulate Filter (DPF). Further downstream, you will find the Selective Catalytic Reduction (SCR) unit and the muffler. Integrated sensors, such as NOx, temperature, and pressure sensors, feed data to the vehicle’s onboard diagnostic system.

Why is the ECU important in this system?

The ECU is the brain of the exhaust system, processing data from various sensors to manage emissions. It monitors backpressure and chemical levels to trigger DPF regeneration or adjust DEF injection. If a sensor reports values outside the normal range, the ECU triggers a check engine light to alert the driver.

What is the difference between DPF and SCR?

The DPF physically traps soot and particulate matter from the exhaust stream, which is later burned off during regeneration. The SCR uses Diesel Exhaust Fluid (DEF) to chemically convert harmful nitrogen oxides into harmless nitrogen and water vapor. Both are critical for meeting emission standards and avoiding an engine derate.

How do I use a 6.7 Cummins exhaust system diagram?

Use the diagram to pinpoint the exact location of a failing component when an OBD-II scanner reveals a diagnostic code. It helps you identify which sensor needs testing or replacement and ensures you follow the correct sequence during disassembly. It is an indispensable tool for accurate troubleshooting and repair.