A 6.0 Powerstroke serpentine belt diagram illustrates the precise path the drive belt takes around pulleys like the alternator, water pump, and AC compressor. Using this visual guide ensures proper tension and prevents a check engine light or diagnostic code triggered by cooling or charging failures during a replacement.

📌 Key Takeaways

- Ensures correct belt routing for optimal engine performance.

- Identifying the automatic tensioner pulley is vital for release.

- Always disconnect batteries to prevent accidental ECU damage.

- Check for worn pulleys to avoid future diagnostic codes.

- Use this diagram during routine maintenance or belt failure.

Navigating the engine bay of a Ford Super Duty can be a daunting task, especially when you are faced with the complex routing requirements of a 6.0 powerstroke serpentine belt diagram. Whether you are performing routine maintenance or responding to a snapped belt on the side of the road, understanding the precise path of this accessory belt is crucial for restoring your truck’s functionality. This comprehensive guide provides the technical layout you need, covering both single and dual alternator configurations commonly found in these diesel engines. You will learn the correct installation sequence, the necessary tools required for the job, and critical safety precautions to ensure your engine remains reliable and powerful.

Understanding the 6.0 Powerstroke Serpentine Belt Diagram Components

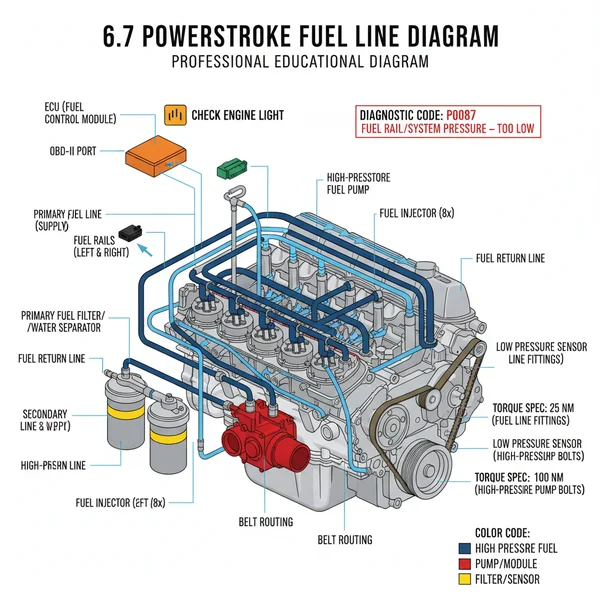

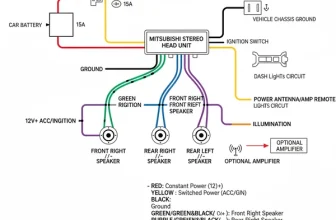

The 6.0-liter Powerstroke engine utilizes a robust serpentine belt system designed to drive several critical engine components simultaneously. Unlike older engine designs that may have used a timing chain to drive accessories, the 6.0 Powerstroke relies on this high-strength rubber accessory belt to maintain the operation of the cooling, charging, and steering systems. The diagram is more than just a map; it is a blueprint for the engine’s mechanical harmony.

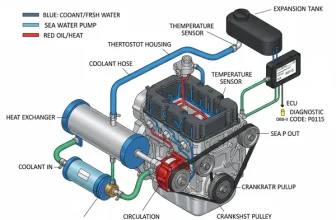

In a standard single-alternator configuration, the belt originates at the crankshaft pulley, which provides the rotational force. From there, it travels to the water pump, which is vital for maintaining consistent coolant flow throughout the engine block and heads. The belt then winds around the power steering pump, the air conditioning compressor, and the alternator. Central to the diagram is the tensioner pulley and one or more idler pulleys, which ensure the belt remains at the correct tension to prevent slipping.

For those with the Heavy Duty or Ambulance package, the 6.0 powerstroke serpentine belt diagram becomes slightly more complex to accommodate a second alternator. The dual alternator setup requires a significantly longer belt and features an additional idler pulley to guide the belt around the secondary charging unit. Regardless of the configuration, the smooth side of the belt always rides on the smooth pulleys (like the water pump or idlers), while the ribbed side of the belt must perfectly seat into the grooved pulleys (like the crankshaft, alternator, and A/C compressor).

[DIAGRAM_PLACEHOLDER: A technical illustration showing the 6.0 Powerstroke engine front view. Labels include: 1. Crankshaft (Bottom), 2. Water Pump (Center), 3. Alternator (Top), 4. A/C Compressor (Left), 5. Power Steering (Right), 6. Tensioner (Lower Right). Arrows indicate belt direction and routing path.]

Most 6.0 Powerstroke engines have a routing sticker located on the fan shroud or the underside of the hood. However, these stickers often peel off over time due to heat, making an external reference diagram essential for DIY repairs.

Step-by-Step Guide to Replacing the Belt Using the Diagram

Replacing the belt on a 6.0 Powerstroke requires patience and the right leverage. Because the engine compartment is tightly packed, following the 6.0 powerstroke serpentine belt diagram precisely is the only way to ensure the belt does not rub against the fan shroud or other stationary components.

Required Tools and Materials

- ✓ 1/2-inch drive breaker bar or long-handled ratchet

- ✓ Flathead screwdriver (for removing intake ducting)

- ✓ New high-quality serpentine belt (specific to single or dual alternator)

- ✓ Work light and mechanics gloves

Installation and Removal Instructions

1. Safety First and Preparation: Ensure the engine is completely cool. Disconnect the negative battery terminals to prevent the engine from accidentally cranking. Remove the plastic air intake ducting to gain better visibility and physical access to the front of the engine.

2. Locate the Tensioner: Find the belt tensioner located on the passenger side of the engine. It features a square 1/2-inch drive hole. Insert your breaker bar into this hole.

3. Release the Tension: Rotate the tensioner clockwise (toward the driver’s side) to compress the spring. While holding the tensioner in this position, carefully slip the belt off the uppermost alternator pulley.

4. Remove the Old Belt: Slowly release the tensioner. Carefully thread the old belt around the cooling fan blades. This can be tricky; you will need to move the belt one blade at a time until it is completely free from the engine.

5. Inspect the Pulleys: Before installing the new belt, spin each pulley by hand. They should spin smoothly without noise or “play.” Check the water pump for leaks, as healthy coolant flow is dependent on a sturdy pump bearing.

6. Route the New Belt: Begin by looping the new belt around the crankshaft pulley at the bottom. Follow the 6.0 powerstroke serpentine belt diagram, threading it around the power steering pump and A/C compressor. Use the “fan blade” method to get the belt behind the cooling fan.

7. Final Seat and Tension: Ensure the belt is perfectly centered in the grooves of all pulleys except the tensioner. Rotate the tensioner again using your breaker bar and slide the belt over the final pulley (usually the alternator or the tensioner itself).

8. Verify the Installation: Double-check every pulley. If the belt is even one “rib” off-center, it will shred within minutes of starting the engine. Ensure the belt is not caught on the fan shroud.

Never place your fingers between the belt and a pulley while the tensioner is being held open. If the breaker bar slips, the tensioner can snap back with enough force to cause severe injury.

Common Issues and Troubleshooting

Even with a perfect 6.0 powerstroke serpentine belt diagram, issues can arise. One frequent problem is belt squeal. This is often caused by a failing tensioner that no longer provides the necessary pressure, or by a pulley that has become misaligned. If you notice the belt “jumping” or vibrating excessively while the engine is idling, the tensioner assembly likely needs replacement.

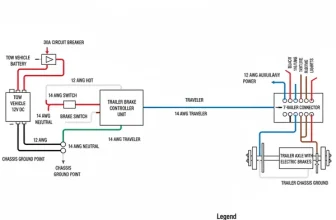

Another critical issue involves the vehicle’s electronics. If the belt slips or breaks, the alternator will stop charging the batteries. This often triggers a check engine light or a battery warning light on the dashboard. When using an OBD-II scanner to pull a diagnostic code, you might find codes related to low system voltage (such as P0562). Furthermore, because the belt drives the water pump, a break will cause an immediate spike in engine temperature. The ECU (Engine Control Unit) may force the vehicle into “limp mode” to prevent catastrophic failure from overheating.

If you are experiencing intermittent battery issues or a flickering check engine light, use an OBD-II monitor to check your “Battery Voltage” PID while driving. If the voltage drops below 13.0V while the engine is running, your belt may be slipping under load.

Maintenance Tips and Best Practices

To avoid being stranded, proactive maintenance is key. Most diesel technicians recommend inspecting your serpentine belt every 15,000 miles and replacing it every 60,000 to 100,000 miles, depending on operating conditions. Look for “chunking,” where pieces of the ribs have fallen off, or deep cracks that span across more than three ribs.

When replacing the belt, it is often wise to replace the tensioner and idler pulleys at the same time. These components have bearings that wear out at similar rates to the belt itself. Furthermore, check the torque spec for any pulley bolts you may have loosened; for example, the alternator mounting bolts typically require a specific torque to remain secure under the vibration of a diesel engine.

Investing in a high-quality, name-brand EPDM rubber belt is a cost-saving measure in the long run. Cheap aftermarket belts tend to stretch more quickly, leading to slips that can affect both your charging system and your coolant flow. Always keep your 6.0 powerstroke serpentine belt diagram printed and stored in your glovebox; in an emergency, having that visual guide can save you hours of frustration.

Finally, always ensure your cooling system is in good health. A seized water pump can snap a brand-new belt instantly. By keeping an eye on your diagnostic code history and performing regular visual inspections, you can ensure your 6.0 Powerstroke remains the workhorse it was designed to be. Utilizing a correct 6.0 powerstroke serpentine belt diagram is the first step toward master-level maintenance of your Ford truck.

Frequently Asked Questions

What is a 6.0 Powerstroke serpentine belt diagram?

It is a visual map showing how the long, multi-ribbed belt weaves through various engine accessories. It identifies pulleys for the crankshaft, alternator, and power steering pump. Following this schematic is crucial to ensure every component rotates in the correct direction and receives proper mechanical power for the vehicle.

How do you read a 6.0 Powerstroke serpentine belt diagram?

Start by identifying the crankshaft pulley at the bottom, then follow the arrows or lines indicating the belt’s path. Distinguish between smooth pulleys, which contact the belt’s back, and grooved pulleys, which seat the ribs. This ensures components like the fan clutch function correctly without any mechanical error.

What are the parts of a 6.0 Powerstroke serpentine belt system?

The system includes the crankshaft drive pulley, alternator, water pump, air conditioning compressor, and power steering pump. It also features an automatic tensioner and idler pulleys. These parts work together to drive vital engine systems, while the ECU monitors overall performance and charging system health via various sensors.

Why is the tensioner pulley important?

The tensioner pulley is critical because it maintains the specific pressure needed to prevent belt slippage. If the tensioner fails, you might see a check engine light or hear squealing. Always check that it moves freely and apply the correct torque spec when replacing the assembly components or bolts.

What is the difference between single and dual alternator setups?

A single alternator setup has a simpler routing path with fewer pulleys. Dual alternator configurations require a longer belt and a different diagram to accommodate the second charging unit. Incorrect routing on either setup can trigger a diagnostic code and lead to immediate battery drainage or engine overheating issues quickly.

How do I use a 6.0 Powerstroke serpentine belt diagram?

Use the diagram as a reference while the old belt is being removed or after it has snapped. Verify the path against the pulleys on your engine block. This guide helps you position the belt correctly before releasing the tensioner to lock everything into place safely and securely.