5.7 Liter 5.7 Hemi Serpentine Belt Diagram: Routing Guide

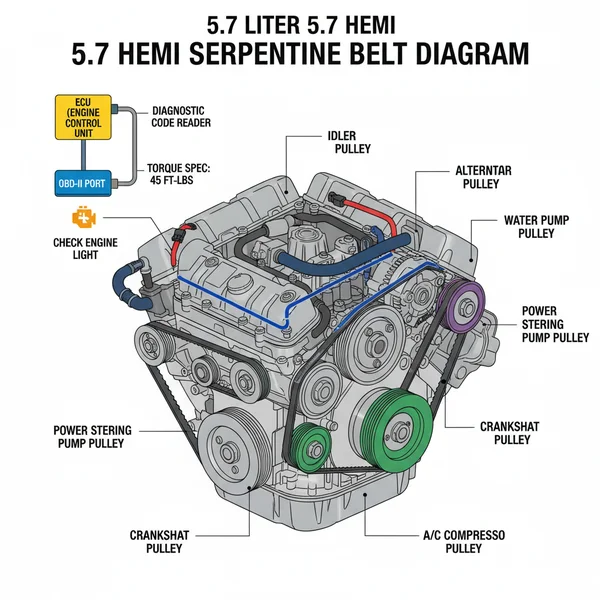

The 5.7 Hemi serpentine belt routing involves the crankshaft, alternator, power steering pump, water pump, and AC compressor. Using a tensioner tool, release pressure to swap the belt. Ensuring proper alignment prevents a check engine light or ECU errors related to charging systems and engine cooling performance.

📌 Key Takeaways

- Visualizing the exact path across the pulleys for the 5.7 Hemi engine

- The automatic belt tensioner is the most critical part for installation

- Always check for pulley misalignment to avoid premature belt wear

- Use a dedicated serpentine belt tool for safe and easy replacement

- Consult this diagram when replacing the alternator or water pump

Finding a clear and accurate 5.7 liter 5.7 hemi serpentine belt diagram is the first and most critical step when performing routine maintenance or emergency repairs on your vehicle. The Hemi engine is a powerhouse of engineering, but its performance relies heavily on the accessory belt to power vital systems like the alternator, water pump, and power steering. Without the correct routing, you risk damaging expensive components or leaving yourself stranded. This article provides a comprehensive breakdown of the serpentine system, ensuring you understand exactly how the belt interacts with every pulley, how to handle the high-tension environment of the 5.7 Hemi, and the technical specifications required to keep your engine running smoothly.

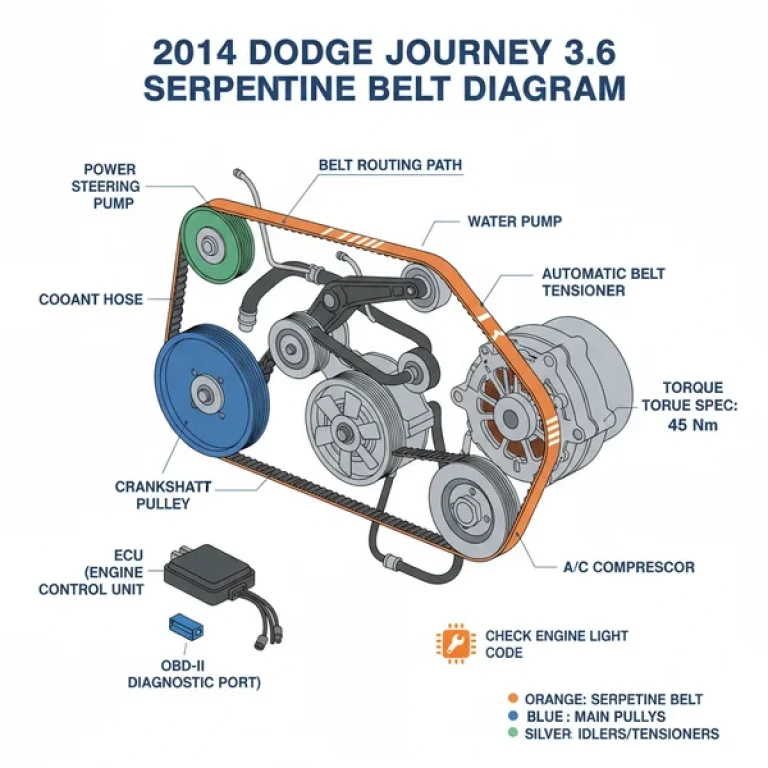

The serpentine system on the 5.7-liter Hemi is designed to be efficient but can appear complex at first glance due to the number of accessories it services. The diagram typically illustrates a “snake-like” path that begins at the crankshaft pulley, which provides the rotational energy for the entire system. From there, the belt travels across various components including the alternator, the air conditioning compressor, the power steering pump, and the water pump. In most configurations, the 5.7 Hemi utilizes a single, long accessory belt, though some heavy-duty versions may have slight variations in idler pulley placement. Understanding the distinction between “grooved” pulleys and “smooth” pulleys is essential; the grooved side of the belt must always make contact with grooved pulleys, while the smooth back of the belt typically rides against the tensioner and idler pulleys.

On the 5.7 Hemi, the water pump is driven by the serpentine belt. If the belt snaps, your coolant flow stops immediately. This can lead to rapid overheating and potential engine failure within minutes, as the ECU will detect the heat spike but cannot physically move the coolant without the pump’s rotation.

To properly interpret the 5.7 liter 5.7 hemi serpentine belt diagram, you must identify each component by its position. The largest pulley at the very bottom center is the crankshaft. Moving clockwise or counter-clockwise (depending on the specific vehicle model like a Ram truck versus a Charger sedan), you will encounter the tensioner. The tensioner is a spring-loaded arm that maintains the perfect amount of pressure on the belt to prevent slipping. If the belt feels loose or squeals during acceleration, the tensioner is often the culprit. Furthermore, the alternator is usually situated near the top of the engine block for better heat dissipation and easier access. The A/C compressor is typically mounted lower on the side. Each of these components must be perfectly aligned; even a slight deviation in pulley depth can cause the belt to “walk” off the tracks or fray prematurely.

Navigating the installation process requires patience and the right tools. Before you begin, ensure the engine is completely cool to avoid burns. You will need a long-handled 3/8-inch or 1/2-inch drive breaker bar or a dedicated serpentine belt tool. Most 5.7 Hemi tensioners feature a square notch or a bolt head (usually 15mm) specifically designed for this purpose.

- ✓ Step 1: Locate the tensioner pulley and identify the rotation direction needed to release pressure (usually clockwise).

- ✓ Step 2: Insert your tool into the tensioner and apply steady pressure to compress the internal spring.

- ✓ Step 3: While the tension is released, slip the belt off the topmost pulley (usually the alternator or idler) as this provides the easiest access.

- ✓ Step 4: Slowly let the tensioner return to its neutral position. Do not let it “snap” back, as this can crack the housing.

- ✓ Step 5: Remove the old belt and inspect all pulleys for debris, oil contamination, or bearing play. Spin each pulley by hand; they should spin smoothly without noise.

- ✓ Step 6: Begin routing the new belt according to your diagram, starting from the crankshaft and working upward. Leave the tensioner or a smooth idler pulley for the final step.

- ✓ Step 7: Depress the tensioner again and slide the belt into its final position, ensuring every rib is seated perfectly in the grooves.

- ✓ Step 8: Double-check the routing one last time against the diagram before starting the engine.

Never place your fingers between the belt and the pulley while installing. If the tensioner tool slips, the resulting force is enough to cause severe injury. Always handle the belt from the side or use a secondary tool to guide it onto the final pulley.

Safety is paramount during this procedure. While the serpentine belt is an external accessory, its failure has internal consequences. For example, if the belt fails, the alternator stops providing power. The ECU (Engine Control Unit) will immediately detect a drop in system voltage. This will likely trigger a check engine light and store a diagnostic code such as P0562 (System Voltage Low). By understanding the 5.7 liter 5.7 hemi serpentine belt diagram, you can quickly diagnose whether a sudden loss of power steering or a battery warning light is due to a simple belt snap or a more complex electrical failure. Unlike the internal timing chain, which is hidden behind the engine cover and synchronizes the valves, the serpentine belt is visible and should be part of your monthly visual inspection.

Troubleshooting issues with the 5.7 Hemi serpentine system often involves listening for specific noises. A high-pitched squeal usually indicates a glazed belt or a failing tensioner that is no longer applying sufficient pressure. A chirping sound often points to a pulley misalignment or a failing bearing in the water pump or alternator. If you see a check engine light accompanied by a heavy steering feel, the belt has likely slipped or broken entirely.

Using an OBD-II scanner can provide further insight. If the belt is slipping, the alternator might not be spinning at the required RPM, causing the ECU to throw a diagnostic code related to charging inefficiency. Furthermore, because the belt drives the pump responsible for coolant flow, a failing belt will lead to a rapid rise in engine temperature. If you see the temperature needle climbing, pull over immediately. Driving even a short distance without a functioning water pump can warp the cylinder heads on a 5.7 Hemi engine.

When replacing the belt, it is highly recommended to replace the tensioner and idler pulleys at the same time. These components have bearings that wear out at roughly the same rate as the belt. A new, stiff belt can put extra strain on an old tensioner, causing it to fail shortly after the repair.

Maintenance best practices for the 5.7 Hemi involve more than just replacing the belt when it breaks. You should inspect the belt every 30,000 miles for signs of “chunking” (where pieces of the ribs fall off) or transverse cracking. Modern EPDM (Ethylene Propylene Diene Monomer) belts do not crack as obviously as older neoprene belts, so you may need a plastic belt wear gauge to check the depth of the grooves. If the grooves are too deep, the belt will “bottom out” on the pulleys, reducing grip and causing heat buildup.

When purchasing replacement parts, always look for high-quality, heavy-duty belts. The 5.7 Hemi produces significant torque, and cheap, off-brand belts may stretch prematurely under high-load situations. When installing a new tensioner, pay attention to the torque spec for the mounting bolt. For most Hemi engines, the tensioner assembly bolt requires a specific torque spec of approximately 30 to 35 foot-pounds, though you should verify this with your specific service manual. Over-tightening can strip the threads in the aluminum timing cover, leading to an extremely expensive and difficult repair.

Quality components also extend to the pulleys themselves. If you notice any “play” or wobbling in the water pump pulley, it is a sign that the internal seal and bearing are failing. Replacing the water pump on a 5.7 Hemi is a more involved task, but it is much easier to do while the serpentine belt is already removed. Proper coolant flow is the lifeblood of the Hemi engine, and the serpentine belt is the mechanical link that ensures that lifeblood keeps moving.

In terms of cost-saving, doing this job yourself can save anywhere from $100 to $300 in labor costs at a dealership. The parts themselves—a high-quality belt and a new tensioner—usually cost under $150 total. By keeping a printed copy of the 5.7 liter 5.7 hemi serpentine belt diagram in your glove box, you are prepared for roadside emergencies. If you are on a long trip and the belt snaps, having the diagram and a basic tool kit can turn a potentially catastrophic breakdown into a 20-minute roadside fix.

Finally, always ensure the OBD-II system is clear of codes after a belt replacement. If you had a check engine light due to a charging or cooling issue caused by the belt, you may need to clear the diagnostic code using a scanner to return the ECU to its normal operating state. This ensures the vehicle’s computer is no longer compensating for the previous low-voltage or high-heat conditions.

In summary, the 5.7 Hemi is a robust and reliable engine, but it is entirely dependent on the integrity of its accessory drive system. By following the 5.7 liter 5.7 hemi serpentine belt diagram, respecting the tensioner’s power, and monitoring the health of your pulleys and coolant flow, you can ensure your vehicle remains on the road for hundreds of thousands of miles. Whether you are dealing with a routine 100,000-mile service or troubleshooting a mysterious squeak, the information provided here gives you the technical foundation to manage your Hemi’s accessory belt system like a professional. Keep your tools ready, your diagram handy, and always prioritize safety and component quality for the best results.

Step-by-Step Guide to Understanding the 5.7 Liter 5.7 Hemi Serpentine Belt Diagram: Routing Guide

Identify the belt routing using the 5.7 Hemi diagram before removal.

Locate the automatic tensioner pulley and use a 1/2-inch breaker bar.

Understand how to rotate the tensioner counter-clockwise to release the belt.

Apply the new belt starting from the bottom crankshaft pulley upward.

Verify that every bolt meets the manufacturer’s torque spec for safety.

Complete the process by using an OBD-II scanner to clear any diagnostic code.

Frequently Asked Questions

What is 5.7 liter 5.7 hemi serpentine belt diagram?

A 5.7 liter 5.7 Hemi serpentine belt diagram is a visual map showing how the drive belt wraps around engine pulleys. It ensures components like the alternator and water pump spin correctly. Without this guide, improper routing can lead to engine overheating or a failed charging system.

How do you read 5.7 liter 5.7 hemi serpentine belt diagram?

To read the diagram, start at the crankshaft pulley and follow the path clockwise. The diagram distinguishes between the ribbed side of the belt and the smooth side. Ensure the belt grooves line up with the ribbed pulleys to avoid premature wear or throwing the belt during operation.

What are the parts of 5.7 liter 5.7 hemi?

The main parts include the crankshaft pulley, alternator, water pump, power steering pump, and air conditioning compressor. It also includes an idler pulley and a spring-loaded tensioner. Each component must be properly engaged by the belt for the ECU to manage the vehicle’s electrical and cooling systems.

Why is the tensioner important?

The tensioner ensures the belt remains tight against the pulleys. If it fails, the belt slips, potentially triggering a check engine light. The ECU may then log a diagnostic code related to low voltage or overheating. Using an OBD-II scanner helps verify if the tensioner is the root cause.

What is the difference between ribbed and smooth pulleys?

Ribbed pulleys are designed to grip the inner side of the belt to provide traction for heavy loads like the alternator. Smooth pulleys contact the flat backside of the belt. The diagram illustrates which side of the belt should touch each specific pulley for proper engine timing.

How do I use 5.7 liter 5.7 hemi serpentine belt diagram?

Use the diagram as a reference before you remove the old belt. Compare your engine’s layout to the drawing to identify the tensioner location. Once the new belt is threaded, use the diagram to double-check that every loop is seated perfectly before starting the vehicle’s engine.