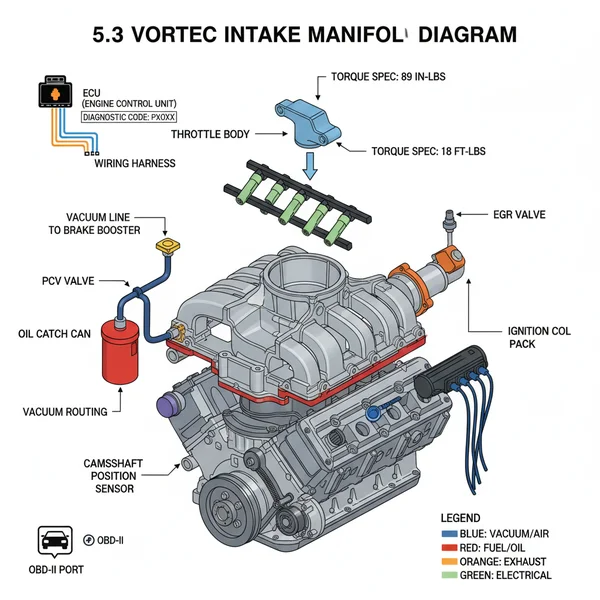

5.3 Vortec Intake Manifold Diagram: Repair & Assembly

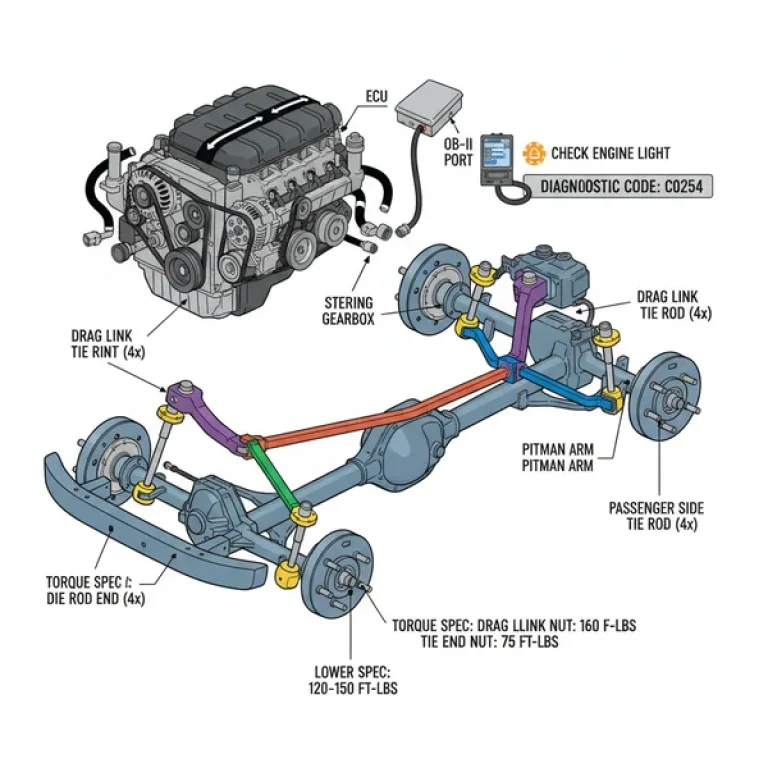

This diagram illustrates the upper plenum, fuel rails, injectors, and vacuum ports essential for airflow management. It helps technicians identify leak points causing a check engine light or diagnostic code. Proper installation ensures the ECU receives accurate sensor data for optimal combustion, fuel efficiency, and overall engine performance.

📌 Key Takeaways

- Visualizing airflow and fuel delivery pathways

- Identifying the intake gaskets and vacuum lines

- Ensuring correct torque spec for plastic manifolds

- Troubleshooting lean codes and rough idling

- Essential tool for gasket replacements or cleaning

Whether you are tackling a rough idle or preparing for a performance upgrade, having a clear and accurate 5.3 vortec intake manifold diagram is the most critical tool in your arsenal. The Vortec 5300, a staple of the GM LS engine family, relies heavily on the integrity of its intake system to maintain the stoichiometric air-fuel ratio required for peak efficiency. In this comprehensive guide, you will learn how to identify every component of the intake assembly, understand the critical torque specifications, and navigate the removal and installation process with professional confidence. This article bridges the gap between basic visual aids and high-level mechanical repair, ensuring your engine breathes correctly and stays free of vacuum leaks.

Detailed Breakdown of the 5.3 Vortec Intake Manifold Diagram

The 5.3 Vortec intake manifold is primarily constructed from a high-density composite plastic designed to reduce weight and minimize heat soak. Unlike older cast-iron or aluminum manifolds, this modern design features integrated channels and specialized sealing surfaces. When viewing a standard 5.3 vortec intake manifold diagram, you will notice several key sub-assemblies. At the leading edge is the throttle body, which regulates air intake based on inputs from the ECU. Surrounding the upper portion of the manifold are the fuel rails, which secure the eight fuel injectors directly over the intake ports.

A critical aspect of the diagram is the distinction between the manifold body and the “valley cover” situated beneath it. In many versions of this engine, specifically the Gen III models, the knock sensors are located in the valley of the engine block, accessible only when the manifold is removed. The diagram also highlights the MAP (Manifold Absolute Pressure) sensor, usually located at the rear or top of the assembly, which provides vital data to the vehicle’s computer system. Understanding the color-coding on high-quality diagrams is also essential: blue or orange seals typically indicate the updated, more resilient gaskets that replaced the problematic early-style teal gaskets.

The manifold also serves as a mounting point for the EVAP solenoid and the PCV (Positive Crankcase Ventilation) tubing. Because the 5.3 Vortec uses a “dry” intake design, you will not see internal coolant passages running through the plastic body. However, the diagram will show the coolant flow via the steam crossover tubes that run underneath the manifold, which are essential for preventing air pockets in the cylinder heads.

[DIAGRAM_PLACEHOLDER: 5.3 Vortec Intake Manifold Assembly – Illustrating Throttle Body, Fuel Rails, MAP Sensor, Intake Gaskets, and Torque Sequence Pattern]

Step-by-Step Guide to Interpretation and Installation

Using a 5.3 vortec intake manifold diagram effectively requires a systematic approach. Whether you are replacing old gaskets or installing a new manifold to clear a diagnostic code, follow these steps to ensure a leak-free seal.

Before starting, always relieve the fuel system pressure at the Schrader valve on the fuel rail and disconnect the negative battery terminal to prevent electrical shorts or fuel ignition.

- ✓ Step 1: Clear the Workspace – Remove the plastic engine cover and the air intake bellows connecting the air box to the throttle body. You may need to move the accessory belt slightly if you are also servicing the alternator for better clearance, though this is usually optional for manifold-only work.

- ✓ Step 2: Disconnect Electrical and Vacuum Lines – Unplug the wiring harness from the eight fuel injectors, the MAP sensor, the EVAP solenoid, and the Throttle Position Sensor (TPS). Reference your diagram to ensure no hidden vacuum lines at the rear of the manifold remain attached.

- ✓ Step 3: Detach Fuel Rails – Using a fuel line disconnect tool, separate the supply and return lines. Remove the four bolts securing the fuel rails and carefully pull the rails and injectors upward. It is often easier to remove the manifold with the rails still attached if you have enough vertical clearance.

- ✓ Step 4: Unbolt the Manifold – There are ten 8mm bolts securing the manifold to the cylinder heads. Follow the reverse of the torque sequence shown in your diagram (working from the outside in) to prevent warping the plastic housing.

- ✓ Step 5: Inspect and Clean – Once the manifold is lifted, immediately cover the intake ports in the cylinder heads with clean shop rags. This prevents debris from falling into the combustion chamber, which could cause catastrophic damage to the valves or timing chain area. Clean the mating surfaces with brake cleaner and a lint-free cloth.

- ✓ Step 6: Install New Gaskets – Snap the new gaskets into the retaining clips on the manifold base. Ensure they sit flush and are not pinched. If your engine has high mileage, this is the ideal time to replace the knock sensors and their associated harness located in the valley.

- ✓ Step 7: Torquing to Spec – Place the manifold back onto the heads. The torque spec is vital: perform a first pass at 44 lb-in (inch-pounds) and a final pass at 89 lb-in. Follow the diagram’s spiral pattern starting from the center bolts and moving outward to ensure even pressure.

Never use foot-pounds (lb-ft) instead of inch-pounds (lb-in) for these bolts. Over-tightening will crack the plastic manifold or strip the aluminum threads in the cylinder heads.

Common Issues & Troubleshooting

The most frequent reason users search for a 5.3 vortec intake manifold diagram is to diagnose a persistent check engine light. Usually, the OBD-II scanner will reveal a diagnostic code such as P0171 or P0174, indicating a “System Too Lean” condition. This is almost always caused by air entering the engine behind the throttle body through a compromised manifold gasket.

Another common issue is the failure of the knock sensors. Because the intake manifold design allows water to pool in the valley, these sensors often corrode. When this happens, the ECU will retard ignition timing, significantly reducing power and fuel economy. Using the diagram to locate the sensor harness allows you to test resistance with a multimeter before committing to a full teardown. If you notice an oily residue inside the manifold during removal, check your PCV system and the coolant flow through the steam vents; while some oil vapor is normal, excessive pooling indicates a failing PCV valve or internal engine wear.

Tips & Best Practices for Maintenance

To ensure longevity after following a 5.3 vortec intake manifold diagram for repair, always choose high-quality, name-brand silicone gaskets. The original factory gaskets were known to shrink in cold weather, leading to vacuum leaks that only appeared during morning warm-ups. The newer “frame-style” gaskets provide a much more reliable seal against the cylinder head’s aluminum surface.

When replacing knock sensors, apply a small bead of RTV silicone around the perimeter of the sensor rubber boots. Leave a small gap at the rear to allow for pressure venting. This “dam” prevents water from entering the sensor wells during engine cleanings or heavy rain.

Additionally, while the intake manifold is removed, take a moment to inspect the surrounding components. Check the accessory belt for cracking and ensure the water pump and steam crossover tubes are not showing signs of seepage. If the engine has significantly high mileage, a visual inspection of the area near the timing chain cover can reveal oil leaks that are easier to fix while the top end is disassembled.

Finally, keep your OBD-II scanner handy for the first few drive cycles after reassembly. It is common to see temporary codes as the ECU relearns the idle air values with a now-sealed system. If the check engine light persists, re-verify your vacuum line connections against the 5.3 vortec intake manifold diagram to ensure nothing was missed during the final installation phase.

In conclusion, mastering the 5.3 vortec intake manifold diagram is about more than just looking at a picture; it is about understanding how air, fuel, and electronics converge in the heart of your engine. By following the correct torque spec, using high-quality components, and being mindful of the delicate plastic housing, you can successfully resolve lean diagnostic codes and restore your vehicle’s performance. Whether you are performing a simple gasket swap or a full manifold replacement, these steps ensure that your 5.3 Vortec remains one of the most durable engines on the road.

Frequently Asked Questions

What is 5.3 Vortec intake manifold diagram?

An architectural map showing how air enters the cylinders, featuring the plenum, fuel injectors, and sensors. It serves as a visual guide for mechanics to locate bolts and vacuum connections, ensuring that the engine maintains a sealed environment for proper fuel-to-air ratios during the internal combustion process.

How do you read 5.3 Vortec intake manifold diagram?

Focus on the sequence of the numbered bolts and the routing of fuel lines. The diagram typically highlights the gasket seating areas and the position of the MAP sensor. Following the numerical pattern is critical to applying the correct torque spec and avoiding warping the composite manifold body.

What are the parts of 5.3 Vortec intake manifold?

Key parts include the upper plenum, throttle body, fuel injectors, and fuel rails. It also houses the manifold absolute pressure sensor and vacuum ports. These components work together to deliver air and fuel while communicating vital pressure data to the vehicle’s ECU for efficient engine management and performance.

Why is the intake gasket important?

The gasket creates a vacuum-tight seal between the manifold and the cylinder heads. If it fails, air bypasses the throttle, triggering a diagnostic code and a check engine light via the OBD-II system. Replacing worn gaskets is a common fix for rough idling and poor fuel economy in trucks.

What is the difference between plastic and metal manifolds?

Older versions of the 5.3 engine used aluminum, while modern ones utilize lightweight composite plastic. Plastic manifolds offer better heat dissipation but are more sensitive to over-tightening. Regardless of material, using the correct torque spec is essential to prevent cracks or leaks that disrupt the ECU’s precise air-fuel tuning.

How do I use 5.3 Vortec intake manifold diagram?

Use it to verify the orientation of the fuel rail and the routing of the wiring harness. It is especially helpful during reassembly to ensure every vacuum hose is connected to the right port. This prevents assembly errors that would otherwise lead to a persistent and frustrating check engine light.