5.3 Chevy Transmission Cooler Lines Diagram: Routing Guide

The 5.3 Chevy transmission cooler lines diagram shows the fluid flow from the transmission to the radiator. The lower line acts as the outlet, while the upper line is the return. Correct routing is vital for the ECU to manage shift quality and prevent a check engine light or transmission overheating.

📌 Key Takeaways

- Identifies the feed and return ports on the transmission housing

- Highlights the connection points at the radiator and auxiliary cooler

- Prevents catastrophic transmission failure by ensuring proper fluid cooling

- Use a line wrench to avoid stripping the fittings during replacement

- Consult this diagram when diagnosing leaks or during a radiator swap

Obtaining an accurate 5.3 chevy transmission cooler lines diagram is a critical first step for any truck owner or mechanic looking to perform maintenance, repairs, or upgrades on their vehicle’s cooling system. The 5.3L V8 engine is a legendary workhorse, but its longevity depends heavily on the health of the transmission. Over time, the lines that transport fluid between the transmission and the radiator can corrode, leak, or become clogged. By understanding the specific layout of these lines, you can ensure that fluid flows efficiently, preventing catastrophic overheating. This guide will provide a comprehensive breakdown of the line routing, how to interpret the technical schematics, and the practical steps required to replace or service these vital components. You will learn not only the “where” but also the “how” and “why” behind your Chevy’s transmission cooling architecture.

Understanding the 5.3 Chevy Transmission Cooler Lines Diagram

The transmission cooler lines for a 5.3L Chevy engine (typically paired with a 4L60E, 4L65E, or 6L80 transmission) serve as the circulatory system for your gearbox. A standard diagram illustrates two primary lines: the “To Cooler” (Hot) line and the “From Cooler” (Return) line. In most Chevy configurations, the hot fluid exits the transmission from the bottom port on the passenger side. It travels forward toward the radiator, where it enters either the radiator’s internal cooling tank or an auxiliary external cooler located in front of the AC condenser.

On the diagram, these paths are often color-coded or labeled with arrows to signify the direction of fluid travel. The hot line is typically indicated in red, while the return line—which carries the cooled fluid back to the top port on the transmission—is shown in blue. If your vehicle is equipped with a Heavy Duty towing package, the diagram will also feature a thermal bypass valve (TBV). This component is designed to keep the fluid within a specific temperature range by recirculating it back to the transmission until it reaches a certain heat threshold, at which point it allows the fluid to pass through the radiator.

Visually, the lines are engineered with specific bends to navigate around the engine block, the exhaust manifold, and the frame rails. The diagram also highlights the connection points, which usually consist of quick-disconnect fittings held in place by “J-clips” or “E-clips.” Understanding these connection styles is paramount, as using the wrong tool can damage the delicate internal seals. Furthermore, the diagram may show the proximity of these lines to the accessory belt and the timing chain cover, emphasizing the importance of securing the lines with factory-style mounting clips to prevent vibration-induced wear.

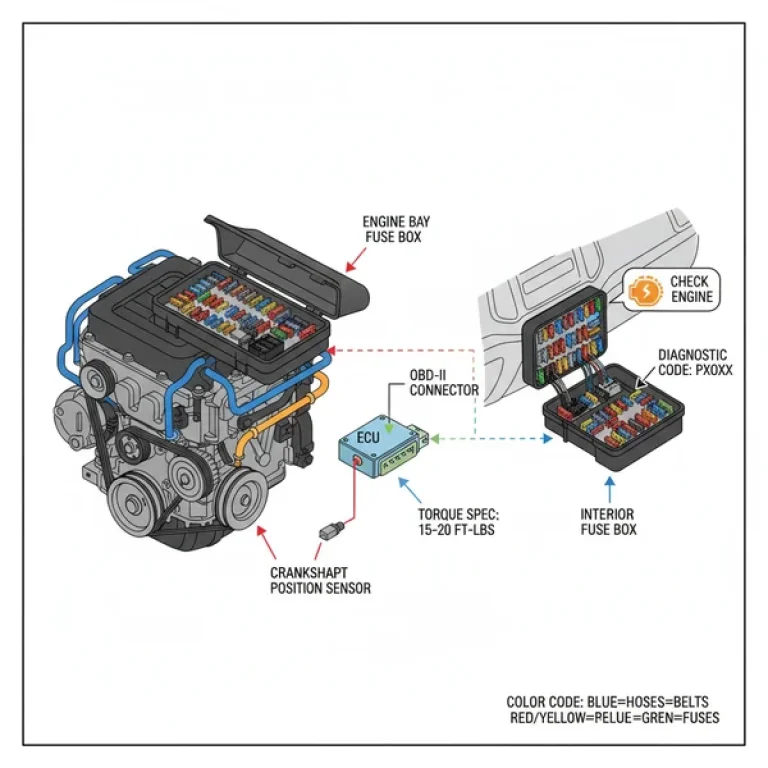

Automotive Schematic: 5.3L Chevy Transmission Cooling System Layout. Features: 4L60E/6L80 Transmission Case Ports, Hot/Cold Flow Identification, Radiator Inlets, and Auxiliary Cooler Integration.

Step-by-Step Guide to Interpreting and Installing Transmission Lines

Reading a 5.3 chevy transmission cooler lines diagram is only half the battle; applying that knowledge requires a systematic approach. Before you begin, ensure you have the proper tools, including a set of quick-disconnect tools, a drain pan, and fresh DEXRON VI fluid.

Most 5.3L Chevy trucks use 3/8-inch or 1/2-inch lines depending on the transmission model. Always verify your fitting size before purchasing replacement parts or disconnect tools.

- Vehicle Preparation: Lift the front of the vehicle using a jack and secure it with jack stands. Remove the plastic splash shield located under the engine to gain access to the radiator connections. This is also a good time to check the accessory belt for wear, as you will be working in close proximity to the front of the engine.

- Identify the Ports: Using your diagram, locate the upper and lower ports on the transmission. On most GM transmissions, the bottom port is the pressure (outlet) side, and the top port is the return (inlet) side.

- Disconnecting the Lines: Slide back the plastic dust caps on the fittings. Use a specialized quick-disconnect tool to spread the internal clip and pull the line outward. Be prepared for fluid drainage; have your pan ready.

- Routing the New Lines: Thread the new lines through the chassis, following the exact path shown in your 5.3 chevy transmission cooler lines diagram. It is crucial to follow the factory routing to avoid heat soak from the exhaust manifolds.

- Seating the Fittings: Push the new lines into the fittings until you hear a distinct “click.” This indicates that the J-clip has locked the flare of the line into place. Tug gently on the line to ensure it is seated.

- Torque and Tightening: If your model uses threaded nut fittings instead of quick-connects, use a flare nut wrench to tighten them. The typical torque spec for these fittings is approximately 18-22 ft-lbs. Do not over-tighten, as the aluminum threads in the transmission case are easily stripped.

- Fluid Refill and Inspection: Once connected, start the engine. Shift through the gears (P-R-N-D) while stationary to circulate the fluid. Check the fluid level using the dipstick and top off as needed.

- Clear Codes: If you experienced a check engine light due to overheating, use an OBD-II scanner to check for a diagnostic code like P0218 (Transmission Over Temperature) and clear it after the repair is verified.

Never attempt to disconnect transmission lines while the engine is hot. The fluid is under pressure and can reach temperatures exceeding 200°F, posing a significant burn risk.

Common Issues & Troubleshooting

The most frequent issue encountered with 5.3 Chevy transmission lines is leakage at the crimp points. These lines are constructed of steel tubing joined to flexible rubber hoses via high-pressure crimps. Over thousands of heat cycles, these crimps lose their integrity. If you notice red fluid pooling under the front bumper or near the bellhousing, the lines are the primary suspect.

Another common problem is the “milkshake” effect. This occurs when the internal cooling tank inside the radiator ruptures, allowing coolant flow to mix with transmission fluid. If your transmission fluid looks like a strawberry milkshake, stop driving immediately. This indicates a failure that the ECU may not immediately detect through a diagnostic code, but it will eventually lead to clutch failure.

The diagram helps solve these issues by allowing you to trace the line back to its origin. For instance, if you see a leak near the timing chain area, the diagram will show that the lines run right along the lower passenger side of the block, helping you distinguish a transmission leak from an oil pan or water pump leak.

Tips & Best Practices for Longevity

To ensure your transmission stays cool and your new lines last for years, follow these professional best practices:

- ✓ Use OEM Replacements: While aftermarket lines are cheaper, OEM GM lines often feature better corrosion-resistant coating and more precise bends.

- ✓ Flush the Cooler: Whenever you replace lines, use a pressurized cooler flush can to blow out debris from the radiator’s internal cooling circuit.

- ✓ Monitor Temperatures: Use your truck’s digital driver information center or an OBD-II monitor to keep an eye on transmission temps. Ideally, it should stay between 160°F and 200°F.

- ✓ Install a Bypass Upgrade: For newer 6L80 transmissions, many owners install a “pill flip” or a thermal bypass delete to ensure constant coolant flow to the cooler, preventing the check engine light from triggering during heavy towing.

Apply a small amount of clean transmission fluid to the end of the new line before pressing it into the quick-connect fitting. This lubricates the internal O-ring and prevents it from tearing during installation.

By utilizing a 5.3 chevy transmission cooler lines diagram and following the detailed steps outlined above, you can confidently manage one of the most vital maintenance tasks for your Chevy truck. Proper routing, secure connections, and regular inspections will keep your transmission running cool, saving you thousands of dollars in potential rebuild costs. Whether you are troubleshooting a leak or performing a preventative upgrade, understanding your vehicle’s fluid dynamics is the hallmark of a savvy DIY mechanic. Always remember to double-check your work, verify fluid levels, and consult your specific vehicle service manual for any model-year variations in torque spec or line diameter.

Frequently Asked Questions

What is 5.3 Chevy transmission cooler lines diagram?

This schematic illustrates the path transmission fluid takes from the 4L60E or 6L80 transmission to the cooling system. It specifies which line is the ‘hot’ outlet and which is the ‘cool’ return. This visual aid is essential for replacing damaged lines or installing an aftermarket auxiliary transmission cooler.

How do you read 5.3 Chevy transmission cooler lines diagram?

Begin at the transmission housing where lines connect to the brass fittings. Trace the bottom line as it travels forward to the lower radiator port. Follow the top line as it returns from the radiator or external cooler back to the transmission, ensuring no kinks or heat-source interference.

What are the parts of 5.3 Chevy transmission cooler lines?

The system includes the metal supply and return lines, rubber hose sections for flexibility, quick-connect clips or threaded fittings, and the radiator interface. High-quality diagrams will also note the mounting brackets that secure the lines to the engine block or frame to prevent vibration-induced leaks or fatigue.

Why is the ECU important for cooling?

The ECU monitors transmission fluid temperature via internal sensors. If the cooler lines are clogged or misrouted, temperatures spike, causing the computer to trigger a check engine light. Using an OBD-II scanner allows you to view real-time data and confirm if the cooling system is functioning within parameters.

What is the difference between outlet and return lines?

The outlet line carries hot fluid from the transmission to the radiator for cooling, typically connecting to the lower port. The return line carries cooled fluid back to the transmission’s upper port. Swapping these can reduce cooling efficiency, potentially throwing a diagnostic code related to transmission fluid temperature.

How do I use 5.3 Chevy transmission cooler lines diagram?

Utilize the diagram to locate the quick-disconnect clips or threaded nuts. It helps identify the specific routing path around the engine oil pan and exhaust. This ensures that every replacement line is seated correctly and helps you follow the correct torque spec to prevent leaks or thread damage.