4l60e Transmission Cooler Lines Diagram: Routing Guide

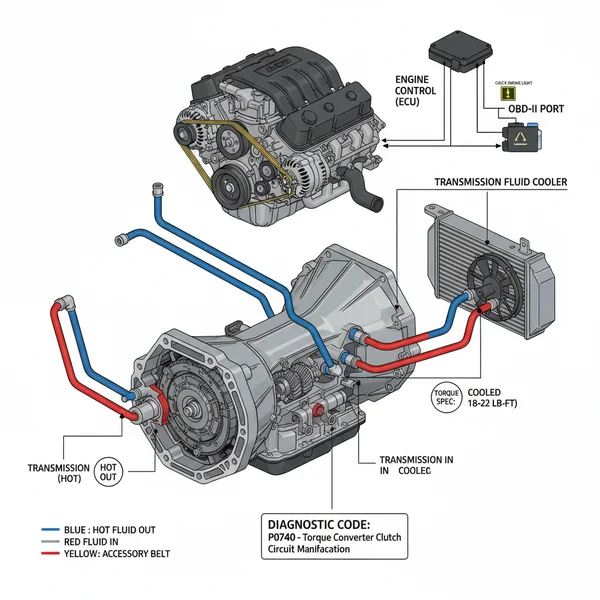

The 4L60E transmission uses two cooling ports: the bottom port is the hot fluid output (to the cooler), and the top port is the return (from the cooler). Proper routing ensures the radiator correctly dissipates heat, preventing internal damage and keeping the fluid at optimal operating temperatures for long-term durability.

📌 Key Takeaways

- Identifies the fluid flow direction between the transmission and radiator

- Distinguishes between the top return port and bottom output port

- Always adhere to the manufacturer torque spec to prevent case damage

- Essential for installing aftermarket external transmission coolers

- Used to troubleshoot overheating issues and fluid blockages

Understanding the 4l60e transmission cooler lines diagram is a fundamental skill for any automotive enthusiast or mechanic working on General Motors vehicles. This specific transmission, known for its versatility and widespread use in trucks, SUVs, and rear-wheel-drive cars, relies heavily on a consistent and pressurized flow of transmission fluid to maintain its operating temperature. Without a clear map of how these lines route from the transmission case to the radiator or external cooling unit, you risk improper installation that can lead to catastrophic internal failure. In this comprehensive guide, you will learn how to identify the pressure and return ports, the correct routing paths to avoid heat sources, and the technical specifications required to ensure a leak-free seal.

Decoding the 4l60e Transmission Cooler Lines Diagram

The 4L60E transmission features two main ports located on the passenger side of the transmission case. When looking at a 4l60e transmission cooler lines diagram, the most critical piece of information is the orientation of the “out” and “in” lines. On the vast majority of 4L60E units, the top fitting (the one furthest from the transmission pan) serves as the return line, which brings cooled fluid back into the transmission. The bottom fitting (the one closer to the oil pan) is the pressure line, which sends hot fluid out toward the cooling system.

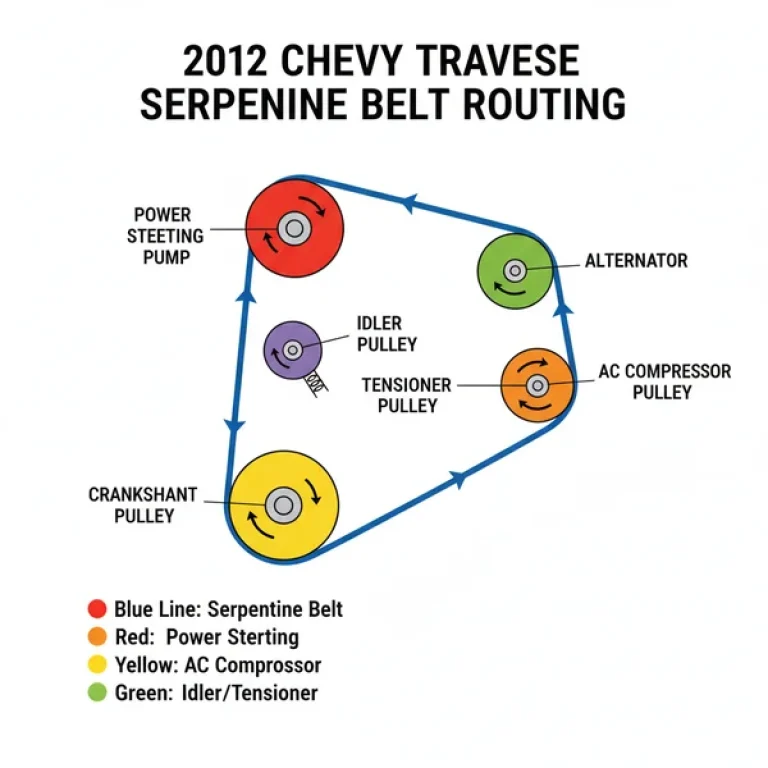

The diagram illustrates how these lines typically exit the transmission and run along the passenger side of the engine block. They are often held in place by specialized clips to prevent them from vibrating against the frame or making contact with moving parts like the accessory belt or the harmonic balancer. In many factory setups, these lines enter the bottom of the radiator first, where the engine’s coolant flow helps dissipate initial heat, before passing through an auxiliary cooler if the vehicle is equipped with a towing package.

Variations in the diagram may occur depending on the specific vehicle model. For example, some trucks utilize quick-connect fittings (Jiffy-tite) that require a specialized tool for removal, while older or heavy-duty applications may use threaded flare fittings. Regardless of the fitting type, the flow direction remains constant: hot fluid exits the bottom port, travels through the cooling medium, and returns through the top port to lubricate the planetary gear sets and cool the clutch packs.

[DIAGRAM_PLACEHOLDER: A technical illustration showing the passenger side of a 4L60E transmission case. The bottom port is labeled “OUTLET / PRESSURE” with an arrow pointing toward the radiator. The top port is labeled “INLET / RETURN” with an arrow pointing back toward the transmission. The lines are shown routing past the engine block to the radiator/transmission cooler.]

Identifying the ports correctly is vital. Reversing the lines won’t necessarily stop the vehicle from moving immediately, but it significantly reduces cooling efficiency and can cause the transmission to run significantly hotter than intended, leading to premature clutch wear.

Step-by-Step Installation and Routing Guide

Following a 4l60e transmission cooler lines diagram requires a methodical approach to ensure the lines are not only connected to the right ports but also protected from mechanical and thermal stress. Follow these steps to interpret the diagram and perform the installation:

- ✓ Step 1: Port Identification and Cleaning – Begin by locating the two ports on the passenger side of the transmission. Use a degreaser to clean the area thoroughly. Debris entering the transmission during line replacement can cause valve body clogs or damage the ECU’s ability to regulate shift pressures.

- ✓ Step 2: Prepare the Lines – Whether you are using pre-bent steel lines or high-pressure braided hoses, ensure the fittings match your transmission housing. If your unit uses threaded fittings, check the threads for any burrs.

- ✓ Step 3: Route the Pressure Line – Connect the first line to the bottom port (the “Out” port). Route this line forward along the frame. Ensure it maintains a safe distance from the exhaust manifold and the accessory belt. Heat from the exhaust can pre-heat the fluid, defeating the purpose of the cooling system.

- ✓ Step 4: Connect to the Cooler – Attach the pressure line to the lower fitting on the radiator or external cooler. By entering at the bottom and exiting at the top of the cooler, you ensure that the cooler is completely filled with fluid, eliminating air pockets that reduce efficiency.

- ✓ Step 5: Route the Return Line – Connect the return line to the top fitting of the radiator/cooler and route it back to the top port on the transmission case. This completed loop ensures a continuous cycle of coolant flow.

- ✓ Step 6: Apply the Correct Torque Spec – Using a flare nut wrench, tighten the fittings. For the standard 1/4 NPSM fittings found on many 4L60E cases, the torque spec is typically around 18-22 foot-pounds. Do not over-tighten, as the aluminum transmission case can crack easily.

- ✓ Step 7: Final Inspection and Fluid Level – Once the lines are secured, start the engine and move through the gears. Check for leaks at every connection point.

Never use standard rubber fuel hoses for transmission lines. Transmission fluid operates at high pressures and temperatures that will cause fuel lines to burst or degrade internally, sending rubber particles into the transmission internals.

Troubleshooting Common Cooler Line Issues

Even with a perfect 4l60e transmission cooler lines diagram, issues can arise over time. One of the most common problems is a leak at the transmission case fittings. Because these lines are subject to engine vibration, the seals or the lines themselves can fatigue. If you notice a red puddle under the passenger side of your vehicle, the cooler lines are the first place to inspect.

Another frequent issue is internal clogging. If the fluid cannot flow freely, the transmission will overheat rapidly. This often triggers a check engine light on your dashboard. When you connect an OBD-II scanner, you may find a diagnostic code such as P0218 (Transmission Overtemperature Condition) or P0700 (Transmission Control System Malfunction). The ECU monitors the temperature sensor inside the transmission; if it detects that the fluid isn’t being cooled properly due to a kinked line or a blocked cooler, it may put the vehicle into “limp mode” to prevent further damage.

If you are experiencing strange noises that sound like a loose timing chain but change when you shift gears, check your cooler line brackets. If a line is vibrating against the frame, it can create a metallic rhythmic sound that mimics engine internal issues.

Maintenance and Best Practices for Long-Term Reliability

To keep your 4L60E running cool for hundreds of thousands of miles, maintenance goes beyond just following a 4l60e transmission cooler lines diagram during a repair. It is highly recommended to install an auxiliary transmission cooler if you plan on towing or driving in mountainous terrain. When adding an external cooler, always route the fluid so it passes through the radiator first and the external cooler last. This ensures the fluid is cooled to the lowest possible temperature before returning to the transmission.

Regularly inspect the lines for any signs of corrosion, especially if you live in a “salt belt” region. Steel lines can rust through, leading to a sudden loss of fluid that can burn up the clutches in seconds. If you are replacing the lines, consider upgrading to nylon-coated or stainless steel options for better corrosion resistance.

Finally, always use high-quality Dexron VI fluid. Modern 4L60E units are calibrated for this synthetic fluid, which offers better thermal stability and flow characteristics than older formulations. When you finish any work on the cooling lines, remember that the total fluid capacity of the system has changed. Always re-check the dipstick while the engine is running at operating temperature to ensure you aren’t running low, which could cause cavitation and foam in the lines, leading to erratic shifting and increased wear.

By strictly adhering to the 4l60e transmission cooler lines diagram and ensuring all fittings meet the required torque spec, you provide your vehicle with the best defense against heat—the number one killer of automatic transmissions. Whether you are troubleshooting a diagnostic code via OBD-II or performing a routine upgrade, precision in your cooling system routing is the key to automotive longevity.

Frequently Asked Questions

What is a 4l60e transmission cooler lines diagram?

A 4L60E transmission cooler lines diagram is a visual reference that shows the path of transmission fluid. It identifies which port on the transmission case sends hot fluid to the radiator and which one receives cooled fluid, ensuring mechanics can correctly install or replace lines without causing circulation errors.

How do you read a 4l60e transmission cooler lines diagram?

To read the diagram, trace the lines from the transmission case to the radiator core. The bottom port on the transmission is the pressure-out line, while the top port is the return. Arrows in the diagram typically indicate the direction of fluid travel through the cooling loop and fittings.

What are the parts of 4l60e transmission cooler lines?

The system includes the output and return lines, quick-connect fittings, and the internal radiator cooler. These components are monitored by the ECU to maintain temperature. If fluid doesn’t flow correctly, it can trigger a check engine light or result in a specific diagnostic code related to transmission overheating.

Why is the 4l60e transmission cooler lines diagram important?

The diagram is vital for preventing transmission failure caused by improper fluid cooling. Incorrectly routed lines can lead to high temperatures, which the OBD-II system will detect. Using the diagram ensures that the fluid passes through the cooling cycle efficiently before returning to lubricate the gear sets and clutches.

What is the difference between output and return lines?

The output line carries hot fluid from the bottom transmission port to the cooling source. The return line brings the cooled fluid back through the top port. Swapping these can reduce cooling efficiency. Monitoring these temperatures via an OBD-II scanner helps verify that both lines are functioning as intended.

How do I use a 4l60e transmission cooler lines diagram?

Use the diagram to verify line placement during a transmission swap or radiator replacement. Match the physical ports on your vehicle to the diagram’s layout. Ensure every fitting is tightened to the proper torque spec to avoid leaks, which could otherwise lead to a drop in pressure and performance.