4 Wire Ignition Switch Bypass Diagram: Troubleshooting Guide

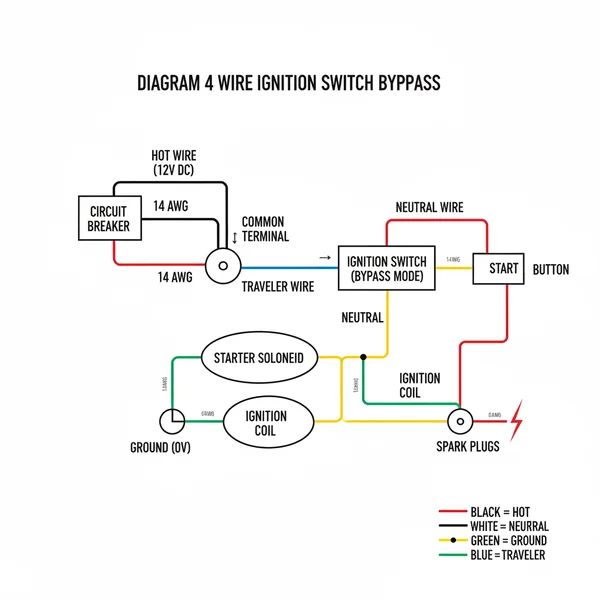

A 4 wire ignition switch bypass diagram illustrates how to bridge the hot wire directly to the ignition and starter circuits. By connecting the common terminal to specific load wires, you bypass a faulty mechanical switch. Proper identification of the ground wire is essential to maintain circuit safety during this diagnostic procedure.

📌 Key Takeaways

- Identifies the electrical path between the battery and starter

- Crucial for identifying the power-in (hot) and output wires

- Always ensure the circuit is fused to prevent electrical fires

- Use a high-quality jumper wire to handle the initial cranking current

- Ideal for emergency starts or diagnosing a failed ignition barrel

Encountering a failed ignition cylinder can be a frustrating hurdle, whether you are dealing with a classic restoration project, a piece of industrial equipment, or an emergency mechanical failure. Understanding a diagram 4 wire ignition switch bypass is essential for diagnosing whether your starting issues stem from the switch itself or a deeper electrical fault. This guide provides a comprehensive breakdown of the internal logic of a four-wire system, detailing how to safely bridge connections to restore power to your engine’s vitals. By the end of this article, you will have the technical confidence to interpret wiring schematics and execute a temporary bypass to get your machine running.

Decoding the 4-Wire Ignition Schematic

A standard four-wire ignition system is designed to manage four distinct electrical states: Off, Accessory, Ignition (Run), and Start. When looking at a diagram 4 wire ignition switch bypass, the most critical step is identifying the function of each terminal. While colors vary by manufacturer, the internal logic remains consistent. You will typically find a heavy-gauge hot wire that provides constant 12V voltage directly from the battery. This is the source of all power for the system and is often connected to a common terminal within the switch housing.

The second wire is the ignition or “Run” wire. This wire provides power to the coil, fuel pump, and engine management systems. Without this connection, the engine may crank but will never fire. The third wire is the starter solenoid wire, which only receives power momentarily when the key is turned to the “Start” position. Finally, the fourth wire is usually dedicated to accessories, such as lights or radio, or it may act as a ground wire or safety interlock traveler wire depending on the specific machine.

In older industrial applications or lawn equipment, you might see these wires attached to a brass screw terminal on the back of the switch. Each terminal is often labeled with a letter: B for Battery (hot wire), S for Starter, I or IGN for Ignition, and A or ACC for Accessories. Understanding this layout is the foundation of any successful bypass, as it prevents accidental shorts that could damage the sensitive voltage regulator or blow high-amperage fuses.

Most 4-wire systems use different wire gauges to indicate power load. The battery and starter wires are typically a thicker gauge (10 or 12) because they carry higher current, while the accessory and ignition wires may be thinner (14 or 16 gauge).

Step-by-Step Guide to Bypassing a 4-Wire Switch

Bypassing an ignition switch requires a methodical approach to ensure you do not create a fire hazard or damage the vehicle’s electrical components. Follow these steps carefully to bridge the circuit correctly.

Step 1: Gather Necessary Tools

Before starting, you will need a digital multimeter to test for voltage, a set of jumper wires with alligator clips (preferably 12-gauge or thicker), and basic hand tools to access the back of the ignition switch. Ensure you have a clear copy of the specific wiring diagram for your model to confirm wire colors.

Step 2: Identify the Hot Wire

Set your multimeter to DC voltage. Place the black probe on a solid ground wire or the metal chassis and touch the red probe to each of the four wires at the back of the switch. The wire that registers a constant 12V (or slightly higher if the battery is fresh) is your hot wire, often referred to as the common terminal feed.

Step 3: Establish the Run Circuit

To mimic the “Ignition On” position, you must connect the hot wire to the ignition wire. Identify the ignition wire using your diagram; it is the one that leads to the engine’s coil or electronic control unit. Use a jumper wire to bridge the hot wire terminal to the ignition terminal. You should hear the fuel pump prime or see the dashboard lights illuminate.

Step 4: Connect the Accessory Wire (Optional)

If you require headlights or other electronics to function while the engine is running, you must also bridge the accessory wire to the hot wire. In many 4-wire configurations, the accessory and ignition wires are both connected to the hot wire during the “Run” phase.

Step 5: Engage the Starter Solenoid

This is the most critical and dangerous step. To crank the engine, you must momentarily bridge the hot wire to the starter wire (the traveler wire leading to the solenoid). As soon as the engine fires and begins to run on its own, you must immediately remove this jumper. Leaving the starter wire connected while the engine is running will cause the starter motor to stay engaged, leading to mechanical failure and potential fire.

Step 6: Confirm Engine Operation

Once the engine is running, ensure your “Run” jumper (Battery to Ignition) remains securely in place. If this connection drops, the engine will die instantly because the coil will lose its power source.

Never leave a bypass unattended. Since the “Off” position is effectively disabled, the engine will continue to run until the wires are physically disconnected. Additionally, bypassing safety switches like the neutral wire interlock can allow the engine to start while in gear, posing a significant safety risk.

Troubleshooting Common Bypass Issues

Even with a perfect diagram 4 wire ignition switch bypass, things can go wrong. If the engine fails to crank, the most common culprit is a poor ground wire connection. The starter solenoid requires a completed circuit to ground to click over; if the engine block or frame isn’t properly grounded, the bypass will fail.

Another frequent problem is a drop in voltage. If your jumper wires are too thin (a high gauge number), they may resist the current flow, preventing the ignition coil from getting enough juice to create a spark. Always use a gauge that matches or exceeds the factory wiring. If you see smoke or smell burning plastic, a short circuit has likely occurred, possibly because the hot wire touched a neutral wire or the metal housing of the switch.

If the engine cranks but won’t start, check the ignition circuit. Use your multimeter to ensure the “Run” jumper is delivering a full 12V to the coil. If the voltage is low, you may have a parasitic drain or a failing battery.

Best Practices and Safety Recommendations

When performing a bypass, quality of components is paramount. Temporary alligator clips are fine for a quick test, but if the bypass must last for more than a few minutes, use crimp-on spade connectors or a temporary toggle switch. This ensures that vibration won’t shake the wires loose, which could cause a spark near the fuel system.

- ✓ Use heat shrink tubing on any exposed temporary connections to prevent accidental grounding.

- ✓ Label each wire with masking tape before disconnecting them from the switch to ensure you can reinstall a new switch correctly later.

- ✓ Inspect the brass screw terminals for corrosion, as green oxidation can cause high resistance and mimic a dead switch.

- ✓ Always keep a fire extinguisher nearby when working with open electrical circuits and fuel systems.

If you are bypassing the switch because you lost the keys, consider that many modern machines have an immobilizer chip. In those cases, a simple wire bypass will not work because the computer requires a digital handshake from the key. This bypass method is best suited for older vehicles and simple mechanical equipment.

Following a diagram 4 wire ignition switch bypass is a powerful diagnostic technique that allows you to isolate electrical issues and get your equipment moving in a pinch. However, it should never be considered a permanent fix. Ignition switches are designed to handle specific thermal loads and provide safety lockouts that manual jumping cannot replicate. Once you have used this method to confirm the switch is the problem, purchase a high-quality replacement switch that meets the original equipment manufacturer (OEM) specifications to ensure long-term reliability and safety.

Frequently Asked Questions

What is a 4 wire ignition switch bypass diagram?

This diagram is a visual schematic that maps out the electrical connections required to start an engine without a functional ignition switch. It identifies the hot wire providing power, the common terminal used for distribution, and the specific wires responsible for powering the ignition coil and the starter solenoid during the bypass.

How do you read a 4 wire ignition switch bypass diagram?

Start by locating the main power source, usually represented by a hot wire coming from the battery. Follow the lines to the common terminal, which acts as the junction. Use the diagram to distinguish between the ‘on’ position wires and the momentary ‘start’ wire to ensure correct jumping sequence.

What are the parts of a 4 wire ignition switch?

The switch typically consists of a power input terminal, an accessory terminal, an ignition terminal, and a starter terminal. In some wiring configurations, a traveler wire may be used to bridge terminals, while a ground wire or neutral wire ensures the circuit is completed safely back to the battery’s negative post.

Why is the ground wire important?

The ground wire is vital because it completes the electrical loop. Without a solid connection to the chassis or battery negative, current cannot flow through the hot wire to the starter. A poor ground connection often causes a bypass to fail or results in intermittent sparking and potential heat damage.

What is the difference between a hot wire and a neutral wire?

The hot wire carries active voltage from the battery to the ignition components. In contrast, a neutral wire or ground wire provides the return path for the current. Distinguishing between these is critical, as accidental contact between a hot wire and a ground wire will cause a short circuit and blown fuses.

How do I use a 4 wire ignition switch bypass diagram?

Use the diagram to identify which two terminals must be jumped to simulate the ‘run’ position. Once the ignition circuit is hot, the diagram shows which traveler wire to momentarily touch to the battery source to engage the starter. This allows for safe engine starting when the key mechanism fails.