4.3 Vortec Intake Manifold Diagram: Repair & Assembly

The 4.3 Vortec intake manifold diagram illustrates the upper plenum, lower manifold, and gasket placement critical for engine air-fuel delivery. Using this visual guide ensures correct vacuum line routing and prevents lean conditions. It is essential for identifying sealing points to resolve common coolant leaks and maintaining precise engine performance.

📌 Key Takeaways

- Visualizes the complex sealing arrangement of the upper and lower manifold sections.

- Identifying the fuel injector spider assembly and central port injection system.

- Ensure specific torque spec requirements are met to prevent plastic plenum cracking.

- Use the diagram to trace vacuum leaks causing rough idle or stalling.

- Essential during gasket replacement or clearing carbon buildup in the EGR passages.

Whether you are a seasoned mechanic or a dedicated DIY enthusiast, locating a clear 4.3 vortec intake manifold diagram is the first step in addressing some of the most common performance issues found in Chevrolet and GMC trucks. The 4.3L Vortec V6 engine is a legendary workhorse, but its unique intake design—consisting of a composite upper plenum and a cast aluminum lower manifold—requires precise knowledge to service correctly. This guide is designed to provide you with a comprehensive understanding of the manifold’s architecture, from the routing of vacuum lines to the critical sealing surfaces that prevent internal coolant leaks. By following this technical breakdown, you will gain the confidence to diagnose check engine light issues, replace failing gaskets, and ensure your fuel delivery system is operating at peak efficiency.

The 4.3L Vortec engine underwent a major fuel system change in the mid-production cycle, transitioning from Central Port Injection (CPI) to the more reliable Multi-Port Fuel Injection (MPFI). Always verify your specific fuel injector type before ordering replacement gaskets or components based on your diagram.

The 4.3 vortec intake manifold diagram typically illustrates a “split-level” design. The upper section, often referred to as the plenum, is made of a high-strength composite plastic. This component houses the throttle body, the Manifold Absolute Pressure (MAP) sensor, and the Exhaust Gas Recirculation (EGR) valve interface. The diagram will show several vacuum ports located at the rear and sides of the plenum, which provide the necessary suction for the brake booster, PCV system, and HVAC controls. Beneath this sits the lower intake manifold, a heavy-duty aluminum casting that manages the primary air induction into the cylinder heads and facilitates coolant flow between the two banks of the engine.

In a standard visual breakdown, the lower intake manifold features six distinct intake runners and four coolant passages. Two of these passages are located at the front of the manifold, near the thermostat housing, while the other two are at the rear. The diagram also highlights the central cavity where the “spider” fuel injector assembly resides. This assembly is a hallmark of the 4.3L design, featuring a central fuel meter body with six nylon fuel lines extending out to the individual intake ports. Understanding this layout is vital because the fuel lines are tucked hidden beneath the upper plenum, making the diagram your only “eyes” inside the engine before disassembly. Color-coded versions of these diagrams often use blue to indicate coolant pathways and red or yellow to indicate fuel pressure lines and return lines.

[DIAGRAM_PLACEHOLDER: A detailed 3D exploded view of a 4.3L Vortec V6 intake manifold. Labels include: 1. Upper Composite Plenum, 2. Lower Aluminum Intake, 3. Spider Injector Assembly, 4. Thermostat Housing, 5. Intake Manifold Gaskets, 6. MAP Sensor, 7. Fuel Pressure Regulator.]

Interpreting a 4.3 vortec intake manifold diagram requires a systematic approach to ensure that every bolt, sensor, and hose is accounted for during a repair. Follow these steps to navigate the manifold removal and installation process successfully:

1. System Preparation and Safety: Before referencing the diagram for component removal, you must depressurize the fuel system. Locate the Schrader valve on the fuel rail (usually indicated on the diagram near the rear of the manifold) and bleed the pressure into a container. Disconnect the negative battery terminal to prevent any electrical arcs near fuel vapors.

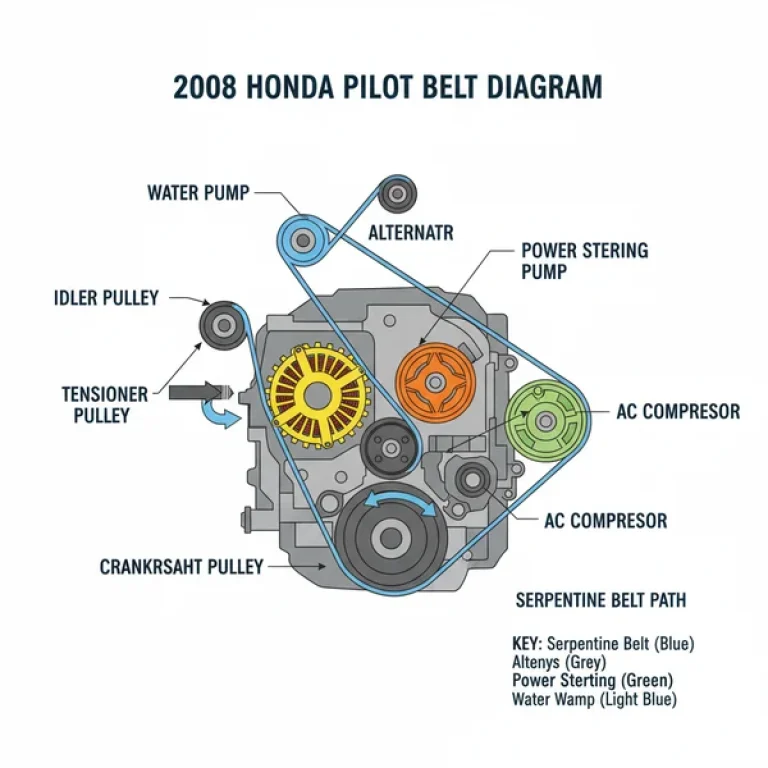

2. Clear the Accessory Path: The 4.3L engine uses a complex accessory belt drive. You must remove the serpentine belt and, in many cases, the alternator and AC compressor mounting brackets. The diagram will show how these brackets are bolted into the front of the cylinder heads and the lower intake manifold itself.

3. Upper Plenum Removal: Using your diagram as a map, disconnect the electrical connectors for the MAP sensor, TPS (Throttle Position Sensor), and IAC (Idle Air Control) valve. Remove the bolts securing the plastic upper plenum to the lower intake. Be careful not to drop debris into the open fuel injector area once the plenum is lifted.

4. Disconnect the ECU Harness: The engine wiring harness that communicates with the ECU (Engine Control Unit) runs across the top of the manifold. Carefully label and move these wires aside. Reference your diagram to ensure you have disconnected the spider injector main electrical plug, which is located centrally on the manifold.

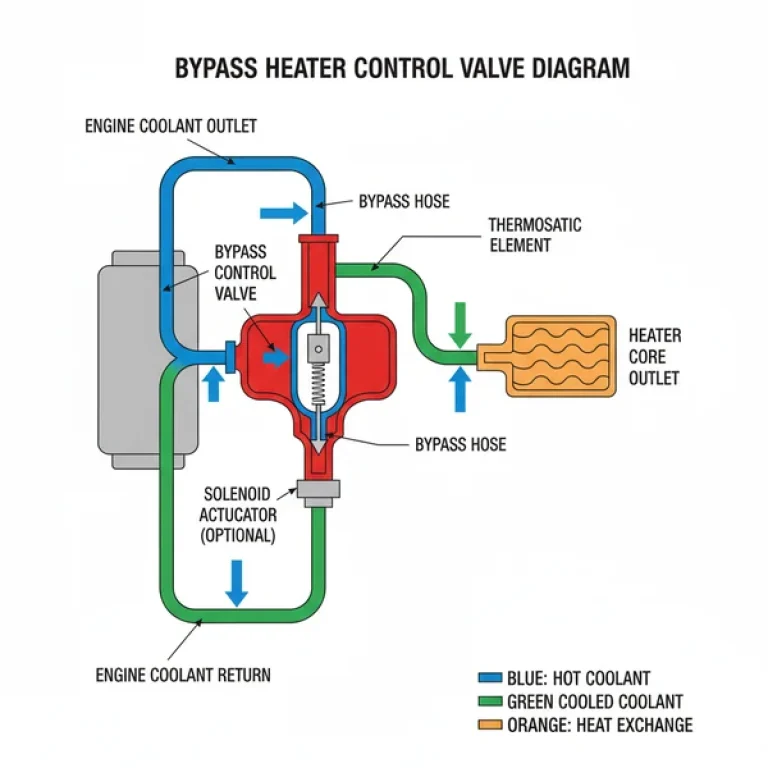

5. Lower Intake Extraction: This is the most critical phase. The lower intake manifold is held down by eight vertical bolts. The 4.3 vortec intake manifold diagram will indicate the location of these bolts, as well as the coolant bypass hose and heater core supply lines that must be detached. Once the bolts are removed, the manifold may be “stuck” due to old gasket material; gently pry it upward without gouging the aluminum surfaces.

6. Surface Preparation: Once the manifold is removed, clean the mating surfaces on the cylinder heads and the manifold itself. Do not use power tools or abrasive pads that can remove metal, as this will lead to a permanent vacuum or coolant leak.

7. Installation and Torque Sequence: When reinstalling, refer to the torque spec section of your diagram. For the 4.3L, the lower intake manifold bolts must be tightened in a specific “criss-cross” pattern to ensure even pressure. Typically, this is done in three passes, ending at approximately 11 to 13 foot-pounds (check your specific service manual for exact figures).

Never reuse the old intake manifold bolts if they show signs of stretching or corrosion. Furthermore, ensure no coolant enters the oil valleys during the swap, as this can cause catastrophic bearing failure shortly after the engine is restarted.

One of the primary reasons users search for a 4.3 vortec intake manifold diagram is to troubleshoot a check engine light or a mysterious loss of coolant. The most frequent issue with this engine is the failure of the lower intake manifold gaskets. The original factory gaskets were made of a plastic carrier that eventually cracks, allowing coolant to leak either externally down the front of the block near the timing chain or internally into the oiling system.

If your OBD-II scanner reveals a diagnostic code such as P0171 or P0174 (System Too Lean), the diagram can help you locate potential vacuum leaks. These leaks often occur at the plenum seal or the PCV hose connections. Additionally, a P0300 (Random Misfire) code may point toward a leaking fuel pressure regulator located inside the plenum. By referencing the diagram, you can identify exactly where the regulator is seated on the injector bracket and check for “washed” areas where raw fuel has cleaned the carbon off the intake runners—a surefire sign of a leak.

- ✓ Coolant in Oil: Often caused by a failure at the rear coolant crossover port.

- ✓ Hard Starting: Likely a leaking fuel pressure regulator or “spider” injector.

- ✓ Rough Idle: Usually a vacuum leak at the upper-to-lower manifold interface.

To ensure a long-lasting repair, always upgrade to “problem-solver” gaskets. These are high-quality components featuring a metal carrier rather than plastic, which resists the corrosive effects of engine coolant much better. When the manifold is off, it is also the perfect time to inspect the accessory belt for cracking and the heater hose quick-connect fittings, which are prone to becoming brittle and snapping.

While you have the upper plenum removed, consider upgrading your SCPI injectors to the newer MPFI style. This eliminates the “poppet” valves that frequently clog and provides much better throttle response and fuel economy.

Regular maintenance of the cooling system is the best way to prevent intake issues. Keeping your coolant fresh prevents the pH levels from becoming acidic, which is the leading cause of gasket degradation in the 4.3L Vortec. If you notice a sweet smell coming from the engine bay or see a small puddle of orange or green fluid near the front of the engine, consult your 4.3 vortec intake manifold diagram immediately. Addressing a small leak today can save you from a complete engine rebuild tomorrow. By combining the visual data from a diagram with the technical steps outlined here, you can maintain the reliability and power of your Vortec V6 for many miles to come.

Step-by-Step Guide to Understanding the 4.3 Vortec Intake Manifold Diagram: Repair & Assembly

Identify the upper plenum and lower manifold components on the diagram.

Locate the specific bolt hole locations and the required torque spec sequence.

Understand how the spider fuel assembly integrates with the internal manifold ports.

Connect the vacuum lines and electrical sensors according to the visual routing guide.

Verify that all gasket surfaces are aligned and free of debris before sealing.

Complete the installation by resetting any stored OBD-II codes after verifying the repair.

Frequently Asked Questions

What is 4.3 Vortec intake manifold diagram?

This diagram is a technical illustration showing the layout of the air intake system for GM’s 4.3L V6 engine. It details the relationship between the upper plastic plenum, the lower aluminum manifold, and the various sensors that send critical data to the vehicle’s ECU for management and fuel trim adjustments.

How do you read 4.3 Vortec intake manifold diagram?

Start by identifying the orientation of the throttle body and the fuel rail. Follow the numbered sequence for bolt tightening to ensure even pressure across the gasket. Look for callouts identifying the MAP sensor, EGR valve, and thermostat housing, which are all integral parts of this specific engine assembly.

What are the parts of 4.3 Vortec intake manifold?

The assembly includes an upper composite plenum, a lower intake manifold, gaskets, and a spider fuel injector unit. It also houses the PCV valve, MAP sensor, and coolant bypass passages. Understanding these parts helps when a diagnostic code indicates a failure in the air induction or fuel delivery system.

Why is torque spec important?

Using the correct torque spec is vital because the upper plenum is made of composite material that can crack if overtightened. Furthermore, the lower intake gaskets require a precise, three-step tightening sequence to prevent coolant from leaking into the engine oil, which can cause catastrophic internal engine damage over time.

What is the difference between upper and lower manifolds?

The upper plenum directs air from the throttle body into the individual cylinders, while the lower manifold distributes that air and contains the coolant crossover passages. A failure in the upper section usually causes vacuum leaks, whereas lower manifold issues often lead to internal or external coolant leaks near the heads.

How do I use 4.3 Vortec intake manifold diagram?

Use the diagram to locate specific vacuum ports and electrical connectors when the check engine light illuminates. It provides a visual roadmap for disassembly and reassembly, ensuring every hose and wire returns to its original position to avoid triggering a new diagnostic code during your initial post-repair test drive.