350 TBI 5.7 TBI Vacuum Diagram: Routing and Repair Guide

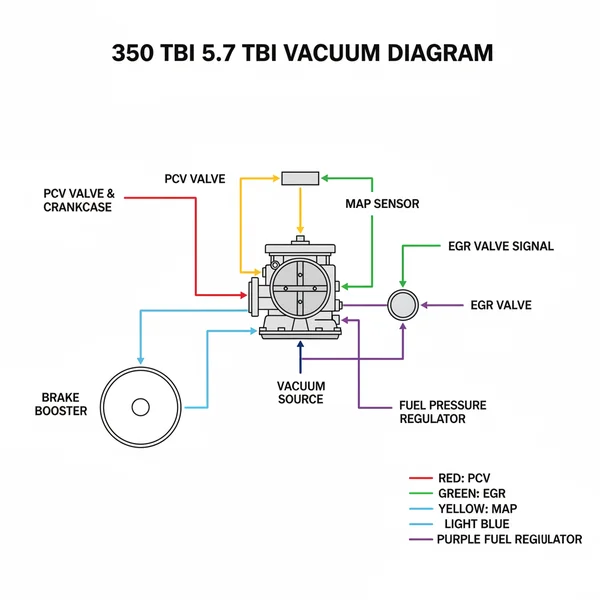

The 350 TBI 5.7 TBI vacuum diagram illustrates the precise layout of hoses connecting the throttle body to components like the EGR valve, MAP sensor, and PCV valve. This system configuration is vital for maintaining engine idle, fuel economy, and emissions. Use this structure to identify leaks or replace aged lines accurately.

📌 Key Takeaways

- Provides a visual map for complex emission and engine management hoses

- The MAP sensor is the most important component to identify for performance

- Always verify hose diameter and heat resistance before replacing lines

- Check for cracks or soft spots in rubber connectors during maintenance

- Use this diagram when diagnosing rough idling or failing emissions

Navigating the engine bay of a classic vehicle powered by the Small Block Chevy can be daunting without the proper documentation. If you are experiencing a rough idle, poor fuel economy, or a failing emissions test, having an accurate 350 tbi 5.7 tbi vacuum diagram is the single most important asset for your diagnostic toolkit. This diagram serves as a roadmap for the intricate web of hoses that manage everything from ignition timing to fuel vapor recovery. By understanding this specific layout, you can ensure your engine operates at its peak efficiency. In this guide, you will learn how to identify every critical component, trace the system configuration, and troubleshoot leaks that often mimic expensive mechanical failures.

Understanding the 350 TBI 5.7 TBI Vacuum Diagram Layout

The 350 TBI (Throttle Body Injection) system is a hybrid of old-school mechanical design and early electronic engine management. Unlike modern vehicles that rely heavily on electronic solenoids, the 5.7 TBI engine utilizes vacuum pressure as a primary signal for several vital sensors and actuators. The diagram illustrates how the throttle body serves as the central hub for vacuum distribution. There are two primary types of vacuum sources you must identify: manifold vacuum and ported vacuum.

Manifold vacuum is present whenever the engine is running and is highest at idle. Ported vacuum, conversely, is non-existent at idle and increases as the throttle plates open. The 350 tbi 5.7 tbi vacuum diagram visually distinguishes these sources to ensure components like the EGR valve and the MAP sensor receive the correct pressure signals at the right time. The system structure is generally divided into three main subsystems: emissions control, engine performance sensing, and accessory drive.

Most TBI units feature three or four vacuum ports on the front and two on the rear. The rear port is typically dedicated to the Power Brake Booster and the PCV valve, as these require the highest volume of manifold vacuum to function correctly.

When viewing a standard 5.7 TBI configuration, you will notice specific color-coding or labeled lines in the diagram. While the physical hoses on your truck may have faded to black over the years, the diagram helps you reconnect the following key components:

- ✓ MAP Sensor (Manifold Absolute Pressure): Usually mounted on a bracket on the firewall or intake manifold, connected via a dedicated hard plastic line.

- ✓ EGR Valve (Exhaust Gas Recirculation): Controlled by a vacuum solenoid; this line is critical for preventing engine pinging under load.

- ✓ PCV Valve (Positive Crankcase Ventilation): A large diameter hose connecting the valve cover to the base of the TBI unit.

- ✓ Charcoal Canister: Part of the EVAP system, this line pulls fuel vapors into the intake to be burned.

- ✓ Thermostatic Air Cleaner (TAC): A small hose running to the “snorkel” of the air filter housing to regulate intake air temperature.

[DIAGRAM_PLACEHOLDER – A detailed technical illustration of the 5.7L TBI throttle body showing the MAP sensor connection, EGR solenoid routing, PCV valve location, and vacuum canister lines.]

Step-by-Step Guide to Routing Your Vacuum Lines

Interpreting a 350 tbi 5.7 tbi vacuum diagram requires a methodical approach. It is not just about connecting point A to point B; it is about ensuring the integrity of the vacuum signal throughout the entire system. Before you begin, gather the necessary tools and prepare the workspace. You will need a handheld vacuum pump, a set of needle-nose pliers, and various sizes of vacuum tubing (usually 5/32″ and 7/32″).

Never attempt to route vacuum lines while the engine is hot. Many vacuum ports are located near the exhaust manifolds, and the risk of burns is high. Additionally, ensure the engine is off to avoid accidental contact with moving fan blades or belts.

Step 1: Identify the MAP Sensor Circuit

Locate the MAP sensor on the firewall. According to the diagram, this sensor must have a clean, unobstructed path to the manifold vacuum port on the throttle body. Use a hard plastic line if possible, as rubber hoses can collapse under high vacuum, sending false data to the ECM (Engine Control Module).

Step 2: Connect the PCV System

The PCV valve is vital for engine longevity. Identify the large port at the rear of the TBI unit. Run a 3/8″ or 11/32″ reinforced vacuum hose from this port to the PCV valve located in the passenger-side valve cover. Ensure the connection is tight; a loose PCV hose is a common cause of high idle speeds.

Step 3: Route the EGR Solenoid and Valve

The EGR system on a 5.7 TBI is controlled by a solenoid. The diagram shows one line coming from a ported vacuum source on the TBI unit to the solenoid, and a second line running from the solenoid to the EGR valve itself. This setup ensures the EGR only opens during cruising speeds and not at idle.

Step 4: Establish the EVAP Purge Line

Find the charcoal canister, usually located in the front corner of the engine bay. Follow the diagram to connect the purge signal line to the designated port on the throttle body. This allows the engine to consume stored fuel vapors safely. If this line is cracked, you may smell raw gasoline around the vehicle.

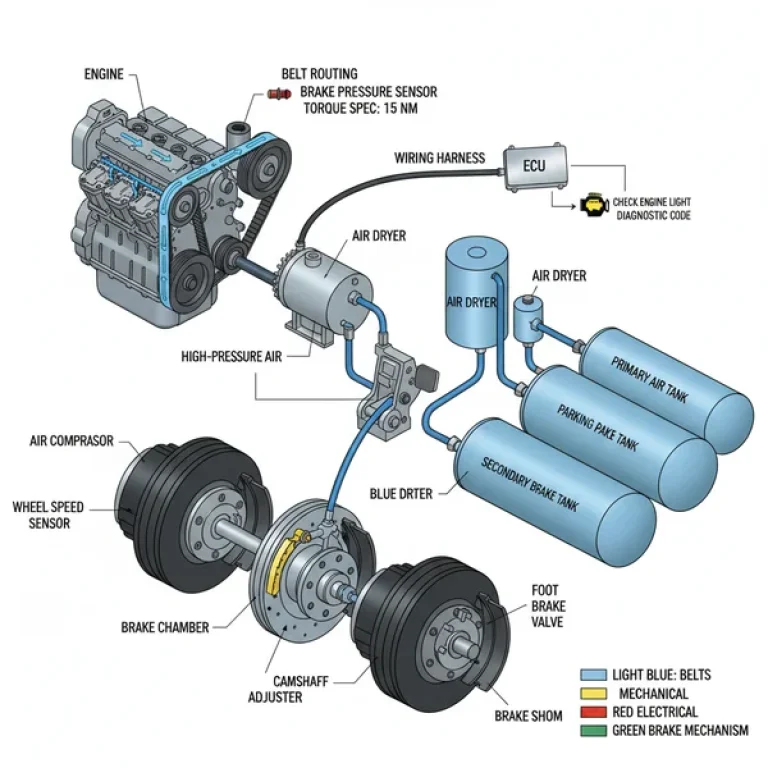

Step 5: Connect the Brake Booster

While often categorized as a brake component, the booster is a massive consumer of vacuum. It connects to the largest threaded port on the back of the intake manifold or the base of the TBI. Use only vacuum-rated hose reinforced with internal braiding to prevent collapse during heavy braking.

If your original vacuum routing sticker is missing from the radiator shroud, take a high-resolution photo of your current setup before disconnecting anything. Even if it is wrong, it provides a baseline for the corrections you will make using the official diagram.

Step 6: Final Leak Test

Once all lines are routed according to the 350 tbi 5.7 tbi vacuum diagram, start the engine. Use a handheld vacuum gauge to verify that the manifold vacuum is steady (typically between 17 and 21 in-Hg for a healthy stock engine). If the needle flickers or stays low, re-check all connections for a snug fit.

Common Issues & Troubleshooting

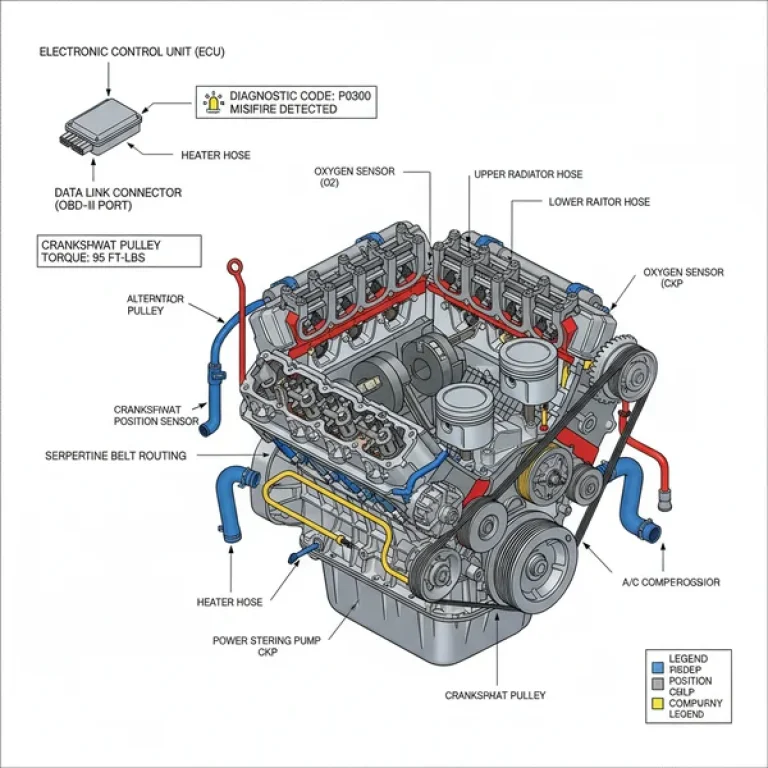

Vacuum leaks are the “silent killers” of TBI engine performance. Because the ECM relies on the MAP sensor to calculate fuel delivery, even a pinhole leak can cause the computer to think the engine is under load, leading to an over-rich fuel mixture. The 350 tbi 5.7 tbi vacuum diagram is your primary tool for isolating these faults. If you notice a “hissing” sound or if your engine stalls when coming to a stop, you likely have a vacuum-related issue.

Frequent problems include the “TBI base gasket leak,” where the gasket between the throttle body and the intake manifold fails. This creates a massive vacuum leak that bypasses the hoses entirely. Another common failure point is the EGR solenoid; if it fails in the open position, vacuum will reach the EGR valve at idle, causing a severe stumble. Using the diagram, you can bypass the solenoid temporarily to test if the idle smooths out, confirming the solenoid is defective.

Watch for dry-rotted rubber elbows. Many TBI systems use specific rubber connectors that transition from hard plastic lines to the TBI ports. Over decades of heat cycles, these become brittle and crack. If your “Service Engine Soon” light is on with codes related to the MAP sensor or Lean Exhaust, consult your diagram and inspect every inch of the corresponding circuit before replacing expensive sensors.

Tips & Best Practices for Maintenance

Maintaining the vacuum system of a 5.7 TBI engine is a low-cost way to ensure long-term reliability. To get the best results from your 350 tbi 5.7 tbi vacuum diagram, consider upgrading your materials. Standard rubber vacuum hoses are prone to heat damage. Replacing them with high-grade silicone tubing can provide a lifetime of service, as silicone remains flexible and resists cracking even in the high-heat environment of a V8 engine bay.

Another best practice is the use of zip ties or small hose clamps on every vacuum junction. While the system operates under negative pressure (which helps pull the hose onto the port), vibrations can gradually wiggle hoses loose. A small zip tie provides cheap insurance against a “mystery” vacuum leak occurring while you are on the road. Additionally, periodically clean the vacuum ports on the throttle body. Carbon buildup can clog the small orifices, particularly the ported vacuum source for the EGR, leading to sluggish performance.

If you are having trouble finding a specific leak, use a can of non-chlorinated brake cleaner or a small propane torch (unlit). With the engine idling, spray or direct the propane around the vacuum lines. If the engine RPM changes, you have found your leak.

In conclusion, the 350 tbi 5.7 tbi vacuum diagram is more than just a drawing; it is a critical diagnostic manual for your engine. By respecting the system configuration and maintaining the integrity of every component, you ensure that your vehicle remains powerful, efficient, and reliable for miles to come. Whether you are performing a full restoration or a simple weekend tune-up, following these steps will help you master the vacuum system of the legendary 350 TBI.

Frequently Asked Questions

What is 350 TBI 5.7 TBI vacuum diagram?

A 350 TBI 5.7 TBI vacuum diagram is a visual schematic that details the layout of the vacuum lines within the engine management system. It identifies how the throttle body connects to the structure of emission components like the PCV valve and charcoal canister to ensure efficient engine performance and idling.

How do you read 350 TBI 5.7 TBI vacuum diagram?

To read this diagram, start at the throttle body injection (TBI) ports and trace each line to its corresponding component. Lines are typically labeled by port letter or color. Understanding the system configuration allows you to see how vacuum pressure flows from the manifold to various actuators and sensors.

What are the parts of 350 TBI 5.7 TBI?

The vacuum system includes several key parts: the MAP (Manifold Absolute Pressure) sensor, EGR valve, charcoal canister, PCV valve, and the vacuum advance for the distributor. Each component plays a specific role in the overall system structure, regulating airflow, emissions, and ignition timing based on engine load and speed.

Why is the MAP sensor important?

The MAP sensor is a critical component because it measures atmospheric pressure and vacuum levels to help the ECM determine fuel delivery. If the vacuum line in this layout is damaged or clogged, the engine will run rich or lean, causing poor driveability, stalling, and decreased fuel efficiency during operation.

What is the difference between ported and manifold vacuum?

Manifold vacuum provides a constant suction source directly from the intake manifold, while ported vacuum is located above the throttle plates and only provides suction as the throttle opens. Distinguishing between these in the diagram is essential for the correct configuration of the vacuum advance and emission control components.

How do I use 350 TBI 5.7 TBI vacuum diagram?

Use the diagram to verify that every hose is connected to the correct port on the TBI unit and the engine. This is especially helpful after an engine rebuild or when troubleshooting vacuum leaks. Comparing your physical layout to the schematic ensures the system operates within factory specifications.