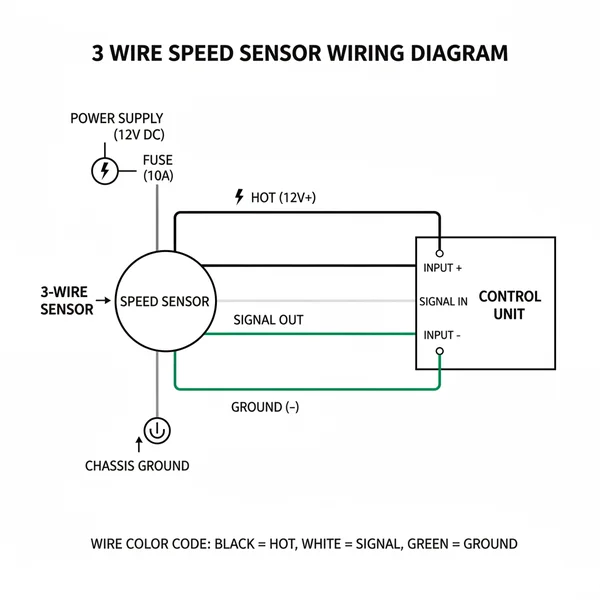

3 Wire Speed Sensor Wiring Diagram: Installation Guide

A 3-wire speed sensor wiring diagram illustrates the essential connections for power, ground, and signal transmission. It typically features a hot wire for voltage input, a ground wire for completing the circuit, and a signal wire that functions like a traveler wire to send frequency data to the common terminal of the ECU.

📌 Key Takeaways

- The diagram identifies power, ground, and signal output leads

- Correct identification of the signal wire prevents ECU damage

- Always verify the voltage requirements of the hot wire before connecting

- Grounding must be secure to prevent signal noise or interference

- Use this diagram for troubleshooting erratic speedometer readings

Finding an accurate 3 wire speed sensor wiring diagram is the first and most critical step for anyone looking to repair an automotive speedometer or install an industrial tachometer. Whether you are working on a transmission, a wheel hub, or a custom engine project, understanding how these sensors interface with your control module prevents costly electrical shorts. A correct diagram ensures you can distinguish between the power supply, the ground reference, and the signal output. In this guide, you will learn the standard pinouts, wire color conventions, and the exact steps needed to wire your sensor correctly to ensure high-precision data transmission.

A 3 wire speed sensor typically functions as a Hall Effect sensor or a magnetoresistive device. The primary components shown in a standard 3 wire speed sensor wiring diagram include the power source (often called the hot wire in general electrical terms), the ground wire, and the signal or traveler wire that sends pulses to the computer. Unlike a 2-wire variable reluctance sensor that generates its own AC voltage, a 3-wire sensor requires an external DC voltage to operate.

_

| |

| SPEED SENSOR BODY |

|_|

| | |

(RED/VCC) (BLK/GND) (WHT/SIG)

| | |

[12V/5V] [GROUND] [SIGNAL]

| | |

(HOT) (COMMON) (TRAVELER)

| | |

V_V_V

| |

| ELECTRONIC CONTROL UNIT |

|_|

Figure 1: Standard DC Speed Sensor Layout with Power, Ground, and Signal output.

In the visual breakdown of the diagram, the three wires are usually color-coded for ease of identification. The power wire is frequently red or orange, carrying a regulated 5V or 12V supply. The ground wire is typically black, acting as the common terminal for the circuit. The third wire, often white, green, or yellow, acts as the signal traveler wire. This wire carries a digital square wave pulse to the speedometer or ECU. While industrial sensors might use a brass screw terminal block for connections, automotive sensors generally use a sealed weather-pack connector. The gauge of the wire is usually between 18 and 22 AWG, depending on the length of the run and the specific voltage requirements of the sensor.

Most modern 3-wire sensors operate on a 5-volt reference signal provided by the Engine Control Module (ECM), though some older systems or heavy-duty machinery may utilize 12-volt “hot wire” systems directly from the battery or ignition switch.

Interpreting a 3 wire speed sensor wiring diagram requires a methodical approach to ensure the sensor detects the rotating reluctor wheel correctly. Follow these steps to complete your installation or diagnostic check:

1. Identify the Sensor Type and Pinout: Look at your specific 3 wire speed sensor wiring diagram to determine which pin corresponds to Power (VCC), Ground (GND), and Signal (OUT). Do not assume that the middle pin is always the ground; different manufacturers use different configurations.

2. Prepare the Wiring Harness: Use the correct gauge wire—typically 20 gauge for signal lines—to minimize resistance. Ensure your wires are clean and stripped approximately 1/4 inch at the ends. If your sensor uses a terminal block, ensure each wire is seated firmly under the appropriate screw.

3. Establish the Common Ground: Connect the ground wire to a reliable common terminal. In automotive applications, this is often the vehicle chassis or a dedicated ground bus. A poor ground is the leading cause of erratic signal “noise” that can lead to false speed readings.

4. Connect the Power Source: Connect the “hot wire” of the sensor to the switched power source indicated in your diagram. This is usually the 5V or 12V reference line. Ensure this circuit is fused to protect the sensor from voltage spikes.

5. Route the Signal (Traveler) Wire: The signal wire acts as the traveler wire between the sensor and the gauge or controller. Route this wire away from high-voltage components like spark plug wires or heavy-duty alternators to prevent electromagnetic interference (EMI) from distorting the pulse.

6. Verify Connections with a Multimeter: Before final assembly, use a multimeter to check for continuity. With the ignition on, verify that the hot wire is receiving the correct voltage and that the common terminal shows zero resistance to the ground.

7. Perform a “Tap Test”: With the sensor wired, you can often test the signal by quickly passing a metal object (like a steel wrench) past the sensor tip. This should trigger a pulse that you can see as a small voltage fluctuation on your meter or a needle jump on your speedometer.

8. Seal and Secure: Once the wiring matches the 3 wire speed sensor wiring diagram and the function is confirmed, use heat-shrink tubing and plastic loom to protect the harness from heat and vibration.

Never connect the signal traveler wire directly to a 12V battery source without a resistor if the sensor is designed for a 5V logic system. Doing so can instantly fry the internal Hall Effect transistor, rendering the sensor useless.

Even with a perfect 3 wire speed sensor wiring diagram, problems can arise during installation. One of the most common issues is a “dead” speedometer caused by an open circuit in the signal wire. If the sensor is getting power and ground but the gauge stays at zero, the traveler wire may have a break. Another frequent problem is a “jittery” needle or erratic speed readings. This is often caused by a loose common terminal or a ground wire that is not making a clean connection to the chassis.

The diagram helps solve these issues by allowing you to perform “back-probing.” By inserting a thin probe into the back of the connector while it is plugged in, you can verify if the voltage is present where it should be according to the diagram. If you see the correct voltage at the sensor but not at the gauge, the fault lies in the wiring harness. If you see erratic pulses when the wheel is spun, the sensor may be spaced too far from the reluctor ring. If you find that the sensor body is physically damaged or if you see a constant voltage on the signal wire regardless of wheel movement, the internal circuitry has likely failed, and it is time to seek professional replacement or a new component.

When wiring long distances, use shielded twisted-pair wire for the signal and ground. Connect the shield to the ground at the controller end only to create a “drain” for electrical interference, ensuring a crystal-clear signal.

To ensure a long-lasting and professional installation, follow these best practices:

- ✓ Match the Gauge: Always match the wire gauge to the factory harness. Using a wire that is too thin can lead to voltage drops, while a wire that is too thick may be difficult to crimp into standard connectors.

- ✓ Use Quality Connectors: Avoid using “vampire” style clip-on connectors. These often cut through the copper strands and lead to corrosion. Use high-quality heat-shrink butt connectors or solder the joints for maximum reliability.

- ✓ Maintain the Gap: The distance between the sensor and the tone ring is vital. Refer to your technical specifications—usually, a gap of 0.030 to 0.050 inches is required for the sensor to pick up the magnetic pulse.

- ✓ Clean the Area: Before installing a new sensor, clean the mounting hole and the reluctor wheel. Metal shavings or grease buildup can interfere with the magnetic field and cause false readings.

Maintenance for your 3 wire speed sensor system involves periodic inspections of the wiring harness. Look for frayed insulation or signs of heat damage, especially if the wires run near the exhaust manifold. If you are working with an AC-style terminal setup, ensure the brass screw is tight and free of oxidation. While a speed sensor is generally a “set it and forget it” component, environmental factors like road salt and moisture can eventually penetrate the weather seals.

By following a comprehensive 3 wire speed sensor wiring diagram and adhering to these technical guidelines, you can ensure your vehicle or machinery operates safely and accurately. Proper identification of the hot wire, signal traveler, and ground wire is the foundation of a successful project, saving you time and money on future repairs.

Step-by-Step Guide to Understanding the 3 Wire Speed Sensor Wiring Diagram: Installation Guide

Identify the power source – Start with identifying the hot wire on the diagram that provides the 5V or 12V supply.

Locate the ground path – Locate the ground wire and ensure it connects to a clean common terminal for a stable circuit.

Understand the signal output – Understand how the signal wire acts as a traveler wire to transmit pulses to the controller.

Connect the multimeter – Connect your testing leads to the pins identified in the diagram to verify proper voltage reaching the sensor.

Verify the signal pulse – Verify that the signal wire shows a toggle between high and low voltage when the sensor detects movement.

Complete the installation – Complete the process by securing all connections and ensuring no wires are crossed, mimicking the diagram’s layout precisely.

Frequently Asked Questions

What is a 3 wire speed sensor wiring diagram?

A 3 wire speed sensor wiring diagram is a visual schematic that maps the electrical paths between a Hall-effect or magnetic sensor and a vehicle’s control module. It details the input power, the return path through a ground wire, and the pulsed signal output used to calculate vehicle or shaft speed.

How do you read a 3 wire speed sensor wiring diagram?

To read the diagram, start at the power source or hot wire and follow the path to the sensor. Identify the common terminal where the ground connects. Finally, trace the signal wire, which acts as the traveler wire, back to the speedometer or computer to understand how data flows through the system.

What are the parts of a 3 wire speed sensor?

The primary parts include the sensor housing, the internal sensing element, and three dedicated leads. These leads consist of a hot wire for DC power, a ground wire for the return circuit, and a signal wire. Some diagrams may incorrectly reference a neutral wire, but in DC speed sensors, this is the ground.

Why is the ground wire important?

The ground wire is critical because it provides the reference point for the sensor’s voltage signal. Without a solid connection to the common terminal or chassis ground, the sensor cannot complete the electrical circuit, leading to a total failure of the speed signal or highly erratic data transmission to the engine computer.

What is the difference between a hot wire and a signal wire?

The hot wire provides constant operating voltage to power the sensor’s internal electronics. In contrast, the signal wire serves as a traveler wire, carrying a fluctuating voltage pulse or frequency back to the ECU. While the hot wire brings energy in, the signal wire sends information out based on rotational movement.

How do I use a 3 wire speed sensor wiring diagram?

Use the diagram to perform point-to-point continuity tests with a multimeter. By identifying which pin corresponds to the hot wire and which is the signal output, you can safely probe the connector without shorting the circuit. It is the primary tool for diagnosing sensor failure versus wiring harness damage.