3 Wire Solenoid Wiring Diagram: Installation Guide

A 3 wire solenoid wiring diagram illustrates the connection between power, ground, and the control signal. Typically, you connect the hot wire to the common terminal and the neutral wire to the return side. The third wire acts as a traveler wire for switching or a dedicated ground wire for safety.

📌 Key Takeaways

- Visualizing power distribution between the control source and the solenoid coil

- Correctly identifying the common terminal to prevent short circuits

- Always ensuring the ground wire is properly bonded for electrical safety

- Using color-coded wires to distinguish between the traveler and hot wire

- Essential for automotive, irrigation, and industrial automation applications

Understanding the intricacies of a 3 wire solenoid wiring diagram is a vital skill for DIY enthusiasts, electricians, and mechanics alike. Whether you are working on an irrigation system, an automotive starter, or an industrial pneumatic valve, the solenoid acts as the bridge between electrical signals and mechanical action. This comprehensive guide provides a clear roadmap for identifying each component, understanding the flow of electricity through the coil, and ensuring a safe, functional installation. By the end of this article, you will be able to confidently interpret wiring schematics, select the correct wire gauge, and troubleshoot common connectivity issues that arise in three-wire configurations.

Understanding the 3 Wire Solenoid Wiring Diagram

When you look at a 3 wire solenoid wiring diagram, you are looking at a map of electromechanical logic. Unlike a simple two-wire version, the three-wire setup often incorporates an additional layer of control or safety. The diagram typically illustrates the internal coil and the three distinct leads exiting the housing. These leads are usually categorized by their function: power, return, and safety. In most standard AC applications, these are referred to as the hot wire, the neutral wire, and the ground wire. In specialized DC applications, such as latching solenoids, the third wire might serve as a signal or traveler wire to toggle the state of the valve.

The visual breakdown of the diagram starts with the solenoid body, represented as a rectangle or a cylinder. Inside this shape, a zig-zag line indicates the electromagnetic coil. The three lines extending from this symbol represent the physical wires you will handle during installation. The common terminal is a central point of the diagram, often serving as the connection for the neutral or return path. If the solenoid is housed in a metal casing, the diagram will show a connection to a brass screw, which serves as the physical grounding point to prevent electrical shocks or equipment damage.

Variations in these diagrams are common depending on the specific application. For example, in a 3-way solenoid valve used for fluid control, the wiring might include a traveler wire that allows a controller to switch the solenoid between an “open” and “closed” state without constant power draw. In automotive contexts, the three wires might include a high-current lead from the battery, a smaller wire from the ignition switch, and a ground. Understanding these nuances is key to preventing a “short to ground” or a “blown fuse” during your project.

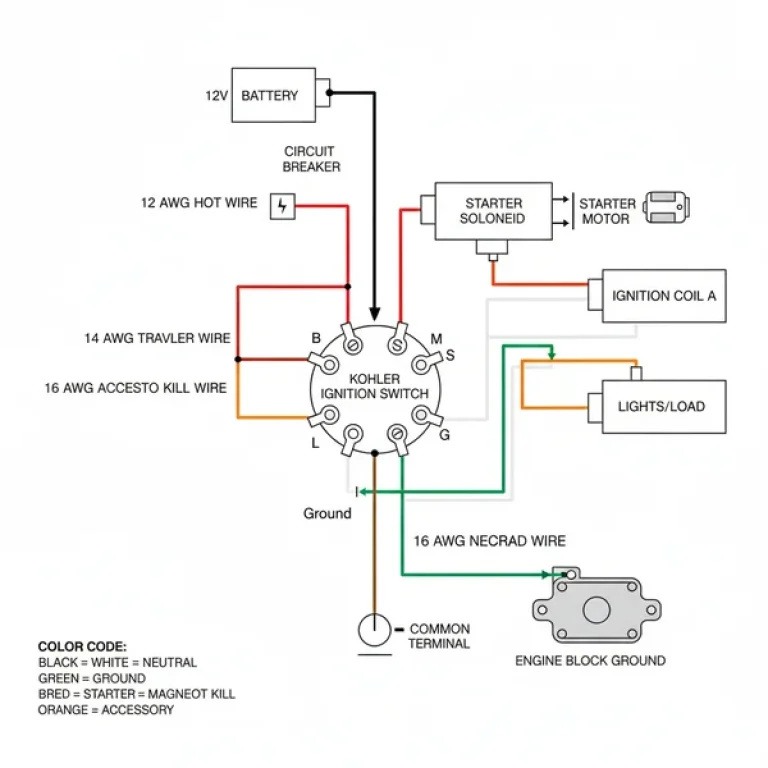

Figure 1: Typical 3-wire solenoid configuration showing Hot, Common, and Ground paths.

Most modern solenoids follow standard color coding: Red or Black for Hot, White or Blue for Neutral/Common, and Green or Bare Copper for Ground. Always verify the voltage requirements on the solenoid’s nameplate before applying power.

Step-by-Step Installation Guide

Properly executing the instructions found in a 3 wire solenoid wiring diagram requires a methodical approach. Before you begin, gather the necessary tools: a wire stripper, a digital multimeter, electrical tape or heat shrink tubing, and a set of screwdrivers. Ensure that the wire gauge you are using is appropriate for the current load. Using a wire that is too thin can lead to a significant voltage drop, which may prevent the solenoid from actuating or, worse, cause the insulation to melt.

Always disconnect the power source before touching any wires. If you are working with 120V or 240V AC, the risk of lethal electric shock is high. Use a non-contact voltage tester to confirm the circuit is dead.

1. Verify Component Specifications: Check the solenoid housing for the rated voltage (e.g., 24V AC, 12V DC, or 120V AC). Match this with your power supply. Check the diagram for the required wire gauge; typically, 18-gauge wire is sufficient for small solenoids, but longer runs may require 14 or 16-gauge to maintain proper voltage.

2. Identify the Ground Path: Locate the ground wire on the solenoid. This is almost always green. If the solenoid has a metal body, there may be a brass screw specifically for this purpose. Connect the ground wire from your power source to this terminal first. This ensures that any internal fault will safely redirect electricity to the earth rather than through you.

3. Connect the Neutral or Common Terminal: In a 3-wire system, the neutral wire (usually white or blue) completes the circuit. Attach this lead to the common terminal identified in your diagram. This terminal is often physically separated from the hot lead to prevent accidental contact. Use a crimp-on spade connector or wrap the wire securely around the terminal screw in a clockwise direction.

4. Wire the Traveler or Signal Lead: If your system uses a traveler wire (common in 3-way configurations), connect it to the designated control output of your switch or PLC. This wire is responsible for sending the “instruction” to the solenoid to change states.

5. Attach the Hot Wire: The hot wire (usually red or black) carries the “load” or power to the device. Connect this to the final remaining terminal on the solenoid. Ensure that no stray copper strands are sticking out, as these can cause a short circuit against the solenoid casing or other terminals.

6. Inspect and Insulate: Review your connections against the 3 wire solenoid wiring diagram. Ensure all screws are tight and that the wires are not under physical tension. Use heat shrink tubing to seal any exposed wire sections, especially if the solenoid is located in a damp environment like an irrigation box.

7. The Multimeter Test: Before applying main power, set your multimeter to the Ohms (Ω) setting. Measure the resistance between the hot and neutral leads. A reading of zero indicates a short, while an “OL” (Open Line) might indicate a broken coil. Refer to the manufacturer’s data for the expected resistance range.

8. Power Up and Actuate: Once you are confident in the wiring, restore power. Actuate the switch or controller. You should hear a distinct “click” as the electromagnetic field pulls the plunger into place. If you hear a loud humming or buzzing without movement, the voltage may be too low or the plunger may be stuck.

When connecting wires to a brass screw or terminal, always loop the wire in the direction the screw turns (clockwise). This pulls the wire tighter as you tighten the screw, rather than pushing it out.

Common Issues & Troubleshooting

Even with a perfect 3 wire solenoid wiring diagram, issues can occur during or after installation. One of the most frequent problems is a “chattering” solenoid. This happens when the device rapidly opens and closes, often due to insufficient voltage reaching the coil. If your wire gauge is too small for the length of the run, the resistance will sap the power needed to hold the plunger steady.

Another common issue is the solenoid failing to release. This can be caused by residual magnetism or a physical blockage in the valve. However, from a wiring perspective, it usually indicates that the traveler wire is receiving a “leakage” current from a faulty controller or switch. You can use your multimeter to check for voltage on the traveler wire when the system should be off.

- ✓ No Click: Check the hot wire for power and ensure the common terminal has a secure path to neutral.

- ✓ Overheating: Verify the voltage. Applying 120V to a 24V solenoid will cause immediate failure and potential fire.

- ✓ Blown Fuses: Look for a ground fault where the hot wire is touching the brass screw or the metal housing.

If the solenoid hums but doesn’t move, the coil is energized, but the mechanical resistance is too high. If there is no sound at all, the break is likely in the electrical circuit. If troubleshooting the wiring doesn’t solve the problem, the internal coil may be burnt out, requiring a replacement of the solenoid unit.

Tips & Best Practices for Longevity

To get the most out of your installation, follow these best practices. First, always use high-quality components. While generic solenoids are cheaper, they often use inferior wire in the coil that can degrade under heat. Look for solenoids with high-quality insulation and clear markings for the common terminal and ground.

Maintenance is also crucial. Over time, vibration can loosen the connection at the brass screw or the hot wire terminal. Periodically check these connections to ensure they remain tight. In outdoor applications, moisture is the enemy of electrical circuits. Use waterproof wire nuts filled with silicone sealant to protect your splices from corrosion. Corrosion increases resistance, which leads to heat and eventual failure.

Regarding cost-saving, the best way to save money is to avoid mistakes. Measuring your run accurately ensures you don’t buy more expensive, heavy-gauge wire than necessary, but never compromise by using a gauge that is too light for the solenoid’s amperage draw. If you are installing multiple solenoids, color-code your traveler wires. Using a different color for each zone or valve will make future troubleshooting significantly easier, as you won’t have to guess which wire leads to which device.

Finally, always keep a copy of your 3 wire solenoid wiring diagram near the control panel. If a failure occurs months or years down the line, having the schematic readily available will save you hours of tracing wires and testing terminals. By following these steps and maintaining a focus on safety and precision, your 3-wire solenoid system will provide reliable service for years to come.

Frequently Asked Questions

What is a 3 wire solenoid wiring diagram?

A 3 wire solenoid wiring diagram is a visual schematic used to map electrical connections for components like fuel shut-off valves or starters. It typically shows how the hot wire provides power, the neutral wire completes the circuit, and the traveler wire facilitates switching between different operational states or provides feedback.

How do you read a 3 wire solenoid wiring diagram?

To read this diagram, start by identifying the power source and following the hot wire to the common terminal. Look for symbols representing the solenoid coil and note how the ground wire connects to the chassis. Pay attention to the traveler wire path, which usually indicates the signal line for activation.

What are the parts of a 3 wire solenoid?

The primary parts include the solenoid body, an internal plunger, and three electrical leads. These leads are usually designated for the hot wire (power), the neutral wire (return), and a third wire that may function as a traveler wire for dual-coil configurations or a dedicated safety ground wire connection.

Why is the common terminal important?

The common terminal is critical because it serves as the central junction where power is distributed to the solenoid’s internal components. Incorrectly wiring the common terminal can lead to a failure in the switching mechanism, potentially damaging the circuit or preventing the traveler wire from triggering the solenoid’s required actuation.

What is the difference between a 2-wire and 3-wire solenoid?

A 2-wire solenoid uses a simple power and return loop. A 3-wire solenoid adds a third connection, often a traveler wire, allowing for more complex functions like high-current pull-in followed by low-current hold-in. This design helps prevent overheating while maintaining a strong magnetic field during the initial actuation.

How do I use a 3 wire solenoid wiring diagram?

Use the diagram as a reference to match physical wires to their corresponding terminals. First, identify the hot wire and neutral wire connections to establish basic power. Then, use the traveler wire to link the control switch. Always verify the ground wire is secure before testing the electrical system.