3 Wire Pressure Sensor Wiring Diagram: Proper Connection

A 3 wire pressure sensor wiring diagram illustrates how to connect the power supply or hot wire, the common terminal for the ground wire, and the signal output. This setup ensures precise monitoring of fluid or gas pressure by transmitting a variable voltage or current signal to a control unit.

📌 Key Takeaways

- The diagram identifies the power, ground, and signal output leads

- Properly identifying the common terminal is essential for signal accuracy

- Always verify voltage requirements before connecting the hot wire

- Use shielded cables to prevent interference on the signal line

- Refer to this diagram during installation or sensor replacement tasks

Implementing a new monitoring system or replacing a faulty component in an industrial or automotive setting often requires a deep dive into electrical schematics. A 3 wire pressure sensor wiring diagram serves as the definitive roadmap for these installations, ensuring that power, ground, and signal pathways are correctly established. Whether you are a DIY enthusiast working on a custom vehicle project or a technician maintaining complex hydraulic machinery, understanding the nuances of these three specific connections is vital. Incorrect wiring can lead to inaccurate data readings, permanent damage to the sensor, or even short circuits within your control module. This article provides a comprehensive breakdown of the wiring process, the physics of the sensor’s operation, and the practical steps needed to achieve a professional-grade installation.

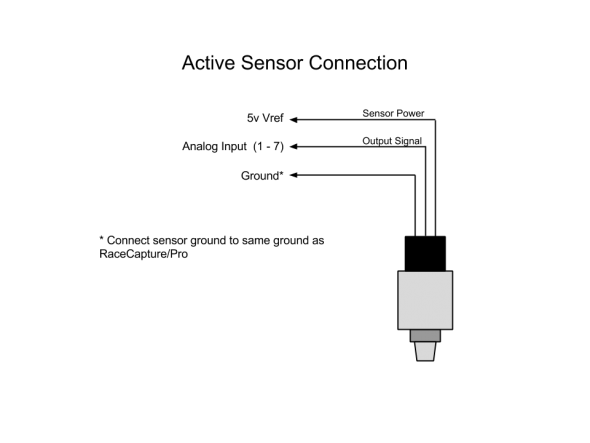

A 3-wire pressure sensor typically operates on a DC voltage system, using one wire for power (excitation), one for ground (reference), and a third for the signal output. This differs from a 2-wire sensor, which uses a current loop (4-20mA) and combines power and signal into the same pair.

Understanding the 3 Wire Pressure Sensor Wiring Diagram

The core of a 3 wire pressure sensor wiring diagram lies in its ability to separate the power source from the data output. This configuration is most commonly found in ratiometric sensors, which provide a voltage output that is a percentage of the input voltage. For example, in a 5V system, the sensor might output 0.5V at zero pressure and 4.5V at maximum pressure. By isolating the signal wire from the power supply, the system reduces the risk of electrical noise and provides a more stable reading for a Programmable Logic Controller (PLC) or an Engine Control Unit (ECU).

When you look at a standard diagram, you will notice three distinct paths. The first is the “hot wire,” which is the positive voltage supply. In DC systems, this is usually labeled as Vcc or +V. The second is the “common terminal” or ground wire, often labeled GND. The third, and arguably the most important for data collection, is the signal wire (Vout). Unlike household AC wiring where you might look for a traveler wire in a three-way switch, DC pressure sensors use these three leads to create a complete circuit that remains constant while the signal fluctuates based on the physical pressure applied to the internal diaphragm.

The color-coding in these diagrams is relatively standardized, though it can vary between manufacturers. Most commonly, you will find:

- ✓ Red Wire: The excitation or “hot wire” (typically 5V, 12V, or 24V DC).

- ✓ Black Wire: The ground or “common terminal” connection.

- ✓ White, Green, or Yellow Wire: The signal output wire that sends voltage to the controller.

In some specific industrial contexts, you might see connections to a brass screw on a terminal block. These blocks are designed to organize the wiring and provide a secure mechanical connection. The diagram will clearly indicate which wire goes to which terminal, ensuring that the voltage delivered to the sensor remains within its specified operating range.

– 3 Wire Pressure Sensor Wiring Illustration showing +Vcc (Red), GND (Black), and Signal (White) connecting to a Controller Terminal Block.

Step-by-Step Installation and Interpretation Guide

Reading a 3 wire pressure sensor wiring diagram is the first step toward a successful installation. However, translating that visual data into a physical setup requires a methodical approach. Follow these steps to ensure your pressure sensor is integrated accurately and safely into your system.

Before touching any wires, ensure the power source is completely disconnected. Even low voltage systems can cause sparks that might damage sensitive electronic components or ignite fumes in automotive environments.

Step 1: Identify your Sensor Pinout

Not every 3-wire sensor uses the same pin configuration. Consult the datasheet for your specific model. The 3 wire pressure sensor wiring diagram provided by the manufacturer will specify if Pin 1 is Power, Pin 2 is Ground, and Pin 3 is Signal, or if they follow a different order. Never assume the order based on another sensor you have used in the past.

Step 2: Gather Your Tools and Materials

You will need a high-quality wire stripper, crimping tools, heat-shrink tubing, and a digital multimeter. Ensure the gauge of the wire you are using matches the requirements of the sensor—usually between 18 and 22 AWG for signal applications. Thinner wire may have too much resistance over long distances, while excessively thick wire may not fit into the brass screw terminals or specialized connectors.

Step 3: Prepare the Ground Connection

In electrical systems, establishing a solid ground is the foundation of a clean signal. Connect the ground wire (usually black) to the common terminal on your controller or the negative post of your power supply. If you are working on a vehicle, this might be a chassis ground, but a direct connection to the ECU’s signal ground is always preferred to avoid “noise.”

Step 4: Connect the Power (Hot Wire)

The “hot wire” provides the necessary energy for the sensor’s internal circuitry to function. Attach this wire to the positive voltage output of your power supply. Ensure the voltage matches the sensor’s rating exactly. If the sensor is rated for 5V and you apply 12V, you will likely destroy the internal piezoresistive element instantly.

Step 5: Integrate the Signal Wire

The signal wire carries the output voltage back to your monitoring device. This wire should be kept as far away as possible from high-voltage AC lines or “traveler wires” in lighting circuits to prevent electromagnetic interference. If the run is long, consider using a shielded cable where the shield is grounded at only one end.

Step 6: Final Terminal Inspection

Check all connections. If you are using a terminal strip, ensure the wires are tucked neatly under the brass screw and that no stray strands are touching adjacent terminals. This is the most common cause of intermittent sensor failure.

Step 7: Verify with a Multimeter

Before plugging the sensor into the controller, turn the power on and use your multimeter to check the voltage between the hot wire and the common terminal. Once confirmed, reconnect the sensor and measure the signal wire relative to ground. At atmospheric pressure (zero PSI), you should see a small, steady voltage (e.g., 0.5V) as indicated by your wiring diagram’s calibration data.

Common Issues & Troubleshooting

Even with a perfect 3 wire pressure sensor wiring diagram, issues can arise during or after installation. The most frequent problem is a “floating signal,” where the output voltage jumps sporadically. This is usually caused by a poor connection at the common terminal. If the sensor doesn’t have a solid reference to ground, the signal has no baseline, resulting in erratic data.

Another common issue is voltage drop. If the gauge of your wire is too small for the length of the run, the voltage reaching the sensor may be lower than required. This will cause the sensor to output a signal that is consistently lower than the actual pressure. You can diagnose this by measuring the voltage directly at the sensor pins while the system is powered.

If you see a “flatline” signal (0V or a constant maximum voltage), it typically indicates a “hot wire” break or a short circuit between the signal and ground. Use the continuity setting on your multimeter to trace each wire back to the source. If the wiring is sound but the sensor still provides no output, the internal diaphragm may be ruptured, or the electronics may have succumbed to an over-voltage spike.

When troubleshooting, always check the “neutral wire” or ground path first. In DC sensor circuits, 90% of signal issues stem from a weak or “noisy” ground connection rather than a faulty sensor.

Tips & Best Practices for Longevity

To ensure your pressure sensor remains accurate for years to come, follow these professional best practices. First, always use shielded twisted pair (STP) wiring for the signal and ground leads. This protects the delicate voltage signal from radio frequency interference (RFI) and electromagnetic interference (EMI) commonly found near motors and relays.

Maintenance is equally important. Periodically inspect the brass screw connections on your terminal blocks. Vibration can loosen these over time, leading to resistance buildup and heat. Applying a small amount of dielectric grease to the connections can prevent corrosion, especially in humid or marine environments where moisture is a constant threat.

When selecting components, don’t skimp on wire quality. Ensure the insulation is rated for the environment; for instance, use cross-linked polyethylene (XLPE) for high-heat automotive engine bays. Additionally, when mounting the sensor, try to avoid locations with extreme vibration. If the sensor must be mounted on a vibrating machine, use a flexible hose to “remote mount” the sensor to a stable bracket, then run your wires according to the 3 wire pressure sensor wiring diagram from that point.

Finally, always keep a copy of your specific 3 wire pressure sensor wiring diagram inside the control cabinet or in your vehicle’s glove box. Future troubleshooting is significantly easier when you don’t have to guess which wire is the signal and which is the power. By following these steps and maintaining a clean, well-documented electrical system, you ensure that your pressure monitoring is both reliable and precise.

In conclusion, mastering the 3 wire pressure sensor wiring diagram is about more than just matching colors. It involves understanding the relationship between the hot wire, the common terminal, and the resulting signal. With the right gauge of wire, proper voltage regulation, and careful installation, your pressure sensor will provide the critical data needed for safe and efficient system operation.

Frequently Asked Questions

What is a 3 wire pressure sensor wiring diagram?

A 3 wire pressure sensor wiring diagram is a visual representation showing the electrical connections between a sensor, its power source, and the receiving device. It details where the hot wire provides power, how the ground wire ensures safety, and which lead transmits the signal back to the control system for data logging.

How do you read a 3 wire pressure sensor wiring diagram?

To read a 3 wire pressure sensor wiring diagram, identify the color-coded lines representing power, signal, and ground. Look for the common terminal that links the negative supply to the signal return. Understanding these symbols ensures you do not confuse the traveler wire paths in complex systems with the direct sensor leads.

What are the parts of a 3 wire pressure sensor?

The parts include the sensing element, internal circuitry, and three external leads. These leads typically consist of a hot wire for excitation voltage, a ground wire for the return path, and a signal wire. Some systems may include a neutral wire or specialized traveler wire setups depending on the industrial automation context.

Why is the common terminal important?

The common terminal is crucial because it acts as the reference point for both the power source and the output signal. In a 3 wire pressure sensor wiring diagram, it ensures that the ground wire maintains a stable zero-voltage baseline, allowing the sensor to provide accurate and consistent pressure readings without electrical interference.

What is the difference between a hot wire and a neutral wire?

In this wiring context, a hot wire carries the positive electrical current from the power source to the sensor. Conversely, a neutral wire or ground wire provides the return path to complete the electrical circuit. While they function differently, both are necessary for the sensor to receive stable power and function safely.

How do I use a 3 wire pressure sensor wiring diagram?

Use a 3 wire pressure sensor wiring diagram by matching the terminal labels on your sensor to the schematic. First, connect the hot wire to the power input. Next, secure the ground wire to the common terminal. Finally, attach the signal output lead to your controller’s input to begin monitoring pressure levels.