3 Wire Headlight Wiring Diagram: Setup and Install Guide

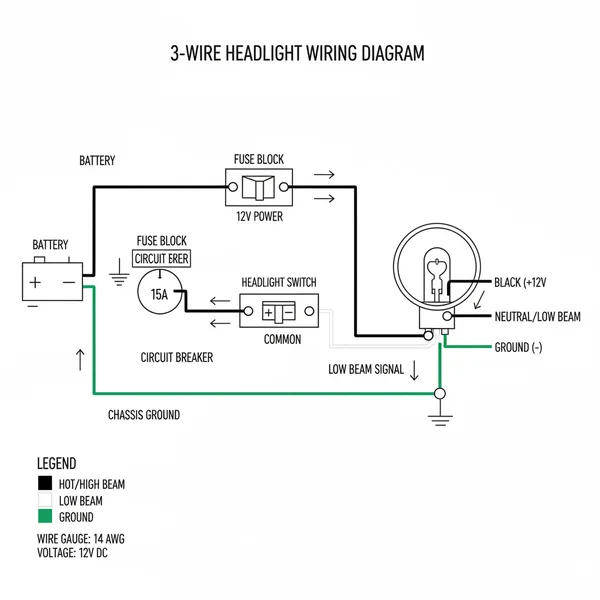

A 3 wire headlight wiring diagram shows the connections for a dual-filament bulb, featuring a high beam lead, low beam lead, and a shared ground wire. By identifying the common terminal on the bulb, you can correctly route the hot wire through the switch to toggle between lighting modes safely.

📌 Key Takeaways

- Illustrates the electrical path for dual-beam headlight systems

- The common terminal is the most critical pin to identify correctly

- Always disconnect the battery to prevent shorts during the wiring process

- Use a multimeter to verify voltage on each lead before final soldering

- Essential for upgrading older halogen systems to modern LED replacements

Understanding a 3 wire headlight wiring diagram is essential for anyone looking to repair, upgrade, or troubleshoot their vehicle’s lighting system. Whether you are dealing with a classic restoration or a modern auxiliary light installation, the 3-wire configuration is the industry standard for dual-filament bulbs like the H4 or 9003 series. Having the correct diagram ensures that your high beams, low beams, and ground connections are properly aligned to prevent electrical shorts or premature bulb failure. In this comprehensive guide, you will learn how to identify each wire, interpret the schematic, and execute a safe installation that maximizes visibility and safety on the road.

Most 3-wire headlight systems utilize a common terminal for the ground, while the remaining two wires act as the “hot” feeds for the low-beam and high-beam filaments respectively. Correct identification of these terminals is critical because reversing them can lead to dim lights or a blown fuse.

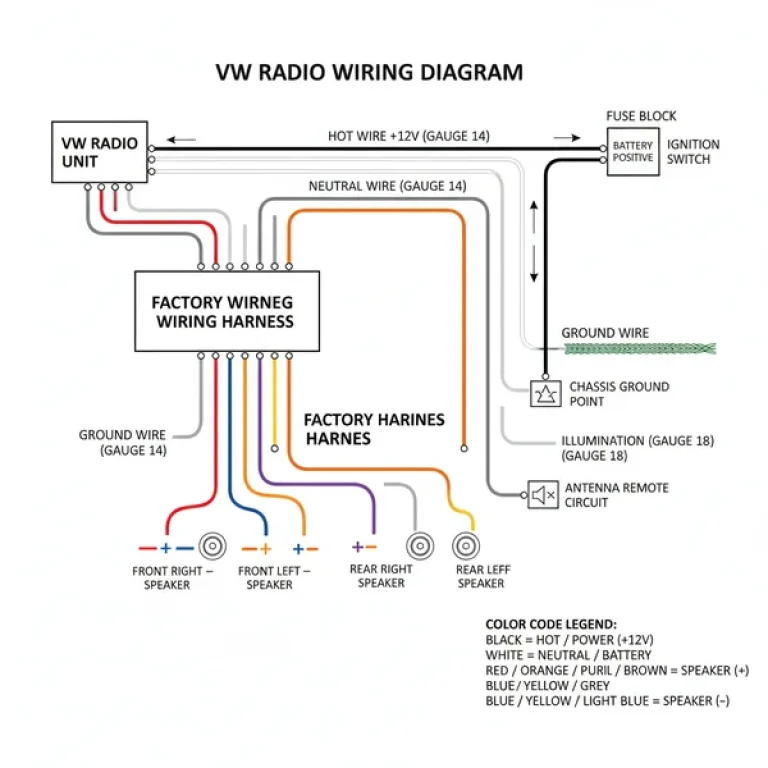

The primary function of a 3 wire headlight wiring diagram is to illustrate the relationship between the power source, the headlight switch, and the bulb filaments. In a standard H4 automotive setup, the three wires are typically categorized as the ground wire, the low beam power wire, and the high beam power wire. When you look at the back of a standard three-prong connector, the orientation is specific: the top horizontal prong is usually the low beam, the left vertical prong is the ground (or common terminal), and the right vertical prong is the high beam. However, this orientation can vary depending on whether the vehicle uses a positive-switched or negative-switched system.

In the diagram, you will notice that the hot wire coming from the battery passes through a fuse and a relay before reaching the headlight switch. This switch acts as a diverter, sending voltage through one of two “traveler” paths. These traveler wires carry the current to either the low-beam filament for standard driving or the high-beam filament for increased visibility. The circuit is completed via the neutral-path ground wire, which must be securely fastened to the vehicle’s chassis or a dedicated grounding block to ensure a consistent return path.

Visual labeling in these diagrams often uses color-coding. While colors vary by manufacturer, a common convention is black for ground, red or white for high beams, and yellow or blue for low beams. If you are working with an aftermarket ceramic socket, you might find a brass screw or terminal at the base of each wire housing to ensure a high-conductivity connection that can withstand the heat generated by high-wattage bulbs.

[DIAGRAM_PLACEHOLDER: A technical schematic showing a 12V battery connected to a 3-way headlight switch. Two traveler wires (labeled High Beam and Low Beam) lead to a 3-prong H4 bulb connector. The third prong is labeled Common Ground and connects back to the negative battery terminal. A relay is positioned between the battery and the switch to protect the circuit.]

To successfully implement a 3 wire headlight wiring diagram, you must approach the installation with a methodical mindset. Following these steps will help you translate the lines on the page into a functioning electrical circuit.

- ✓ 1. Gather Required Tools: You will need a digital multimeter, wire strippers, a crimping tool, heat shrink tubing, and high-quality electrical tape. Ensure your wires are of the correct gauge—typically 14 or 16 gauge for standard headlights to handle the amperage without overheating.

- ✓ 2. Disconnect the Power: Before touching any wiring, disconnect the negative terminal of your battery. This prevents accidental shorts that could damage your vehicle’s sensitive electronic control units.

- ✓ 3. Identify the Common Terminal: Use your multimeter on the continuity setting to test your existing harness. The ground wire will show zero resistance when touched to the chassis. In the context of a 3-wire diagram, this is your common terminal that serves both filaments.

- ✓ 4. Map the Traveler Wires: Identify which wire is energized when the headlight switch is in the “low” position and which is energized during “high” beams. Label these as your traveler wires to avoid confusion during the final assembly.

- ✓ 5. Prepare the Connectors: Strip approximately half an inch of insulation from each wire. If using a replacement socket, ensure the wires are firmly seated. If the socket uses a brass screw termination, loop the wire clockwise around the screw before tightening to ensure a secure mechanical bond.

- ✓ 6. Connect to the Relay: It is highly recommended to use a relay in your 3-wire circuit. Connect the hot wire from the battery to terminal 30 of the relay, and use the signal from your headlight switch to trigger terminal 86. This ensures the full voltage reaches the bulbs directly from the battery rather than passing through thin dashboard wiring.

- ✓ 7. Secure the Ground: Attach the neutral-path ground wire to a clean, unpainted metal surface on the frame. Use a star washer to bite into the metal, ensuring a low-resistance connection that won’t vibrate loose over time.

- ✓ 8. Test the System: Reconnect the battery and test both beam settings. Use the multimeter to verify that you are getting at least 12.6V at the bulb socket while the engine is running.

Never use a fuse with a higher amperage rating than what is specified in your vehicle’s manual. Doing so can cause the wire insulation to melt or lead to an electrical fire if a short occurs.

Even with a perfect 3 wire headlight wiring diagram, issues can arise due to environmental wear or component failure. One of the most common problems is a “dim” headlight, which usually indicates a bad ground. If the common terminal has high resistance due to corrosion, the electricity cannot efficiently return to the battery, causing the bulb to glow faintly. Another frequent issue is the “high beam indicator” on the dashboard staying on even when low beams are selected; this often happens if the traveler wires are crossed or if there is feedback through the ground circuit.

If you notice flickering, check the voltage at the connector. If the voltage fluctuates rapidly, your relay might be failing or the wire gauge might be too thin for the current load.

If you encounter a situation where both filaments are illuminated simultaneously, you likely have a short between the two traveler wires. This generates excessive heat and will quickly burn out the bulb or melt the plastic connector. If your troubleshooting leads you to a complex computer-controlled lighting module (BCM) and you cannot find a physical wiring fault, it may be time to consult a professional automotive electrician, as modern CAN-bus systems can be sensitive to DIY modifications.

To ensure long-term reliability of your 3-wire system, always use automotive-grade components. Standard residential wire is not designed to withstand the heat, vibration, and chemical exposure found in an engine bay. When selecting wire, choose “cross-linked” polyethylene (TXL or GXL) which has a high heat resistance.

Furthermore, always apply a small amount of dielectric grease to the bulb prongs before inserting them into the connector. This prevents moisture from entering the terminal and causing oxidation, which is the leading cause of “melted” headlight sockets. If you are upgrading to high-output halogen or LED bulbs, verify that your existing wire gauge can handle the increased current. Many factory harnesses use thin 18-gauge wire that can cause a significant voltage drop, reducing the brightness of your new bulbs. Upgrading to a dedicated 14-gauge relay harness can often increase light output by 20% or more simply by reducing electrical resistance.

Finally, keep a copy of your specific 3 wire headlight wiring diagram in your vehicle’s glovebox. Should you experience a failure while traveling at night, having the schematic on hand will make roadside repairs significantly faster and safer. By following these best practices and understanding the fundamental principles of traveler wires and common terminals, you can maintain a lighting system that is both powerful and dependable.

Step-by-Step Guide to Understanding the 3 Wire Headlight Wiring Diagram: Setup And Install Guide

Identify the three main leads—high beam, low beam, and ground—using the wiring schematic.

Locate the common terminal on the headlight socket to ensure proper orientation of the plug.

Understand how the hot wire transitions power through the headlight switch or relay system.

Connect the ground wire to a clean, unpainted metal surface to ensure a solid electrical return.

Verify that the traveler wire or main harness pins are securely seated within the weather-proof connector.

Complete the installation by testing the beam functionality and ensuring no neutral wire interference exists in the circuit.

Frequently Asked Questions

What is 3 wire headlight wiring diagram?

This diagram is a visual schematic used to map out the electrical connections for a three-terminal headlight bulb. It illustrates how the hot wire from the battery reaches the high and low beam filaments. It also identifies the ground wire path necessary to complete the circuit for safe vehicle operation.

How do you read 3 wire headlight wiring diagram?

Start by locating the bulb symbol and identifying the three distinct terminals. Follow the lines representing the high and low beam circuits back to the relay or switch. Notice where the ground wire attaches to the chassis, and ensure the hot wire paths are fused to prevent electrical fires.

What are the parts of 3 wire headlight wiring?

The system consists of a dual-filament bulb, a socket, and a wiring harness. Key internal components include the low beam lead, the high beam lead, and a shared common terminal. In some specialized configurations, a traveler wire might be mentioned, while a neutral wire reference typically applies to AC-converted systems.

Why is common terminal important?

The common terminal is vital because it acts as the shared return or supply point for both filaments in the bulb. If this terminal is wired incorrectly, the headlights may dim, flicker, or fail to switch between beams. It ensures the circuit remains stable regardless of which beam is currently active.

What is the difference between ground and hot wire?

The hot wire carries 12V power from the battery through the switch to the bulb filaments. The ground wire provides the return path to the battery, completing the loop. Unlike a house circuit where you have a neutral wire, automotive systems use the vehicle frame as a massive ground return.

How do I use 3 wire headlight wiring diagram?

Use the diagram as a blueprint for repairing damaged sockets or installing aftermarket lights. Match the wire colors on your vehicle to the functions shown on the schematic. This helps you identify which wire is for the high beam and which is for the low beam to avoid errors.