3 Prong Headlight Wiring Diagram: Easy Installation Guide

A 3 prong headlight wiring diagram maps the connections for dual-filament bulbs, typically featuring a high beam, low beam, and ground. The hot wire delivers power from the battery, while the common terminal serves as the shared connection point. Proper grounding through the ground wire is essential for completing the circuit safely.

📌 Key Takeaways

- Illustrates the electrical paths for both high and low beam circuits.

- Identifying the common terminal is critical for correct pin orientation.

- Always disconnect the battery to prevent shorts during the wiring process.

- Use a multimeter to verify voltage on the hot wire before connecting bulbs.

- Use this diagram when troubleshooting dim lights or installing LED conversions.

Understanding your vehicle’s lighting system is essential for both safety and performance on the road. This guide provides a detailed 3 prong headlight wiring diagram to help you navigate the complexities of automotive illumination. Whether you are replacing a damaged socket, upgrading to high-performance bulbs, or troubleshooting a dark lamp, knowing the specific layout of your wiring ensures a reliable and safe connection. In this comprehensive article, we will break down the color-coding, terminal identification, and the specific electrical paths required to get your high and low beams functioning perfectly. You will learn about wire gauges, voltage requirements, and how to identify each terminal on the connector to prevent electrical shorts and maximize bulb longevity.

Understanding the 3 Prong Headlight Wiring Diagram

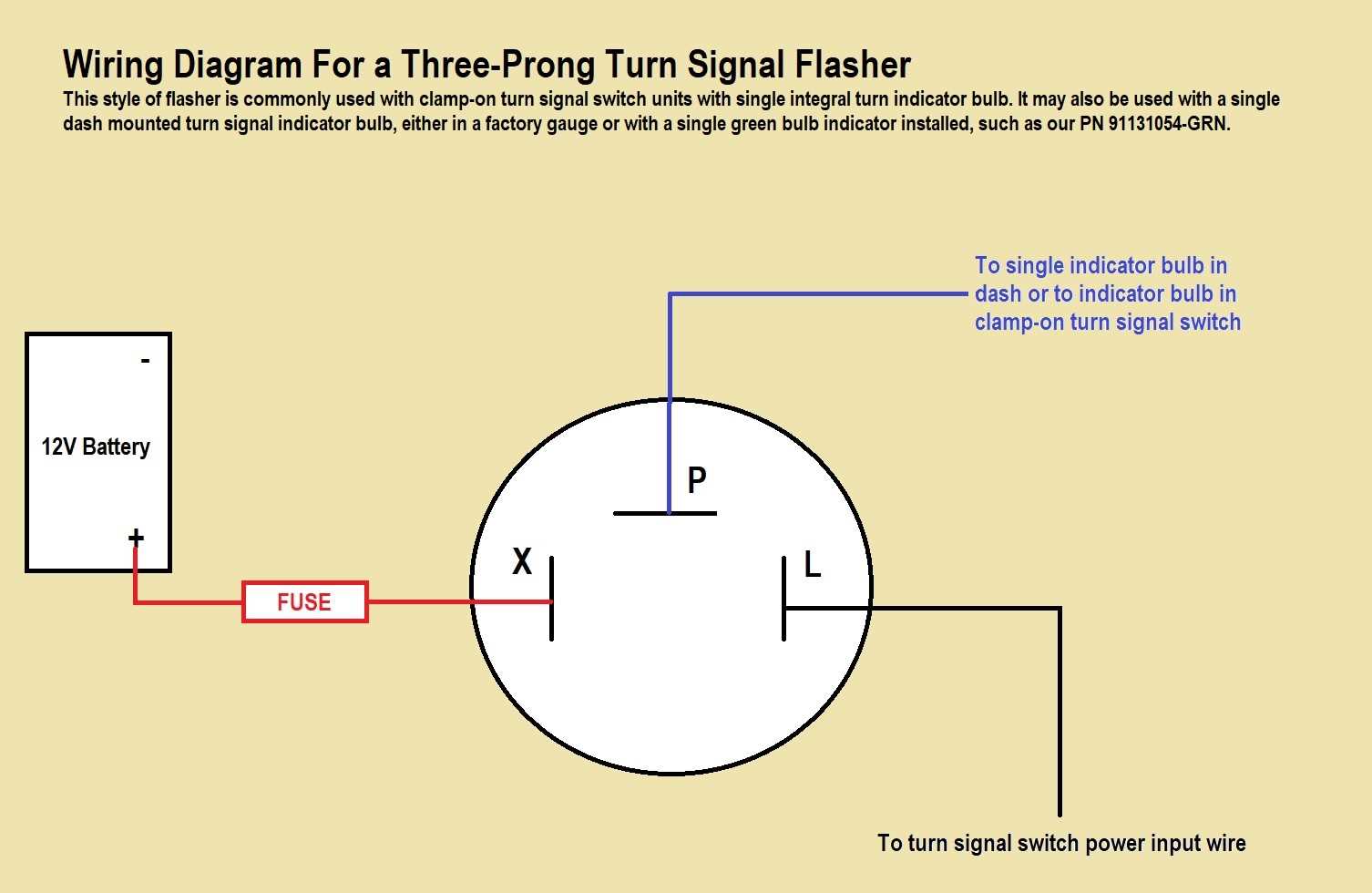

The most common configuration for a three-prong system is the H4 (or 9003/HB2) bulb, which is a dual-filament bulb capable of producing both high and low beams from a single unit. To read a 3 prong headlight wiring diagram correctly, you must first orient yourself by looking at the back of the bulb or the front of the female harness connector. The three metal tabs are arranged in a “U” shape.

In a standard positive-switched system, these three terminals represent the low beam, the high beam, and the ground wire. The ground wire serves as the common terminal in most domestic and European vehicles, providing the return path for the electrical current back to the battery. When you look at the rear of the connector with the middle prong at the top, the top prong is typically the low beam feed, the left prong is the high beam feed (acting as a traveler wire from the light switch), and the right prong is the common ground.

However, variations exist. Some manufacturers utilize a ground-switched system where the common terminal is actually the hot wire (constant 12V), and the light switch completes the circuit by connecting the low or high beam filaments to the ground. This is why a 3 prong headlight wiring diagram is indispensable; it allows you to identify which wire carries the voltage and which serves as the return before you begin cutting or splicing. If these are reversed, you may experience “ghosting,” where both filaments glow dimly, or the bulb may fail to ignite altogether.

Figure 1: Standard H4/9003 Wiring Pinout showing High Beam, Low Beam, and Common Ground configurations.

Step-by-Step Installation and Interpretation Guide

Interpreting a 3 prong headlight wiring diagram requires a methodical approach to ensure the integrity of the vehicle’s electrical system. Before you begin, ensure you have a digital multimeter to verify voltage and continuity.

Most automotive headlight circuits operate on 12 to 14.4 volts. Using a wire gauge that is too thin (higher numerical value) can lead to a voltage drop, resulting in significantly dimmer headlights and potential overheating of the insulation.

Step 1: Safety First

Always disconnect the negative battery terminal before working on the headlight harness. This prevents accidental short circuits that could damage the vehicle’s Body Control Module (BCM) or blow expensive fuses.

Step 2: Identify the Wire Functions

Using your 3 prong headlight wiring diagram as a map, identify the three wires leading to the socket. In many aftermarket harnesses, the hot wire for the low beam is often red or white, while the high beam traveler wire might be blue or green. The ground wire is almost universally black. If you are working with an older vehicle where the colors have faded, use your multimeter to test for 12V at the plug while an assistant toggles the headlight switch.

Step 3: Check Wire Gauge and Condition

For standard halogen bulbs, a 14 or 16-gauge wire is typically sufficient. If you are upgrading to high-wattage bulbs, you may need to step up to 12-gauge wire to handle the increased current draw. Check the insulation for cracks or “green crusties” (copper oxidation), which can increase resistance and drop the voltage reaching the bulb.

Step 4: Connecting the Ground Wire

The common terminal (usually the right-hand prong when viewed from the back) must be connected to a clean, unpainted part of the vehicle chassis or directly back to the battery’s negative terminal. In electrical terms, this is similar to the neutral wire in a household AC circuit, providing the path for current to exit the component.

Step 5: Wiring the Low Beam

Connect the low beam hot wire to the top terminal of the 3-prong connector. This filament is designed for constant use and usually has a shield inside the bulb to direct light downward, preventing glare for oncoming traffic.

Step 6: Wiring the High Beam

Connect the high beam wire to the remaining left-hand terminal. This wire acts as the traveler wire, carrying current only when the steering column stalk is pushed forward or pulled back. Ensure the connection is tight; a loose high-beam connection can arc, melting the plastic housing of the 3-prong socket.

Step 7: Reconnect and Test

Once all wires are secured via soldering or high-quality crimp connectors, reconnect the battery. Test the low beams, then toggle the high beams. If the lights are dim, re-check your ground connection.

Never touch the glass of a halogen bulb with your bare fingers. The oils from your skin can create hot spots on the quartz glass, causing the bulb to shatter or burn out prematurely when it reaches operating temperature.

Common Issues and Troubleshooting

Even with a perfect 3 prong headlight wiring diagram, issues can arise due to environmental factors or aging components. One of the most frequent problems is “single beam failure,” where only the high or low beam works. This is often not a bulb issue, but a failure at the connector. Over time, the heat generated by the bulb can cause the metal terminals inside the socket to expand and lose their “spring,” leading to a poor connection.

Another common symptom is flickering lights. This usually indicates a loose ground wire or a failing relay. In systems that use an external relay, check the brass screw terminals on the relay housing. Corrosion here can restrict current flow, dropping the voltage and causing the lights to pulse. If you find that your fuses are blowing repeatedly, use the diagram to trace the hot wire along the fender well; it is likely rubbing against a sharp metal edge, creating a short to ground.

If both headlights are dim, the issue is likely a high-resistance ground. You can test this by running a temporary jumper wire from the common terminal of the bulb directly to the negative battery post. If the brightness increases, your factory ground path is compromised and needs to be cleaned or replaced with a thicker gauge wire.

Tips and Best Practices for Long-Lasting Headlights

To ensure your wiring job stands the test of time, follow these professional best practices. First, always use dielectric grease inside the 3-prong connector. This silicone-based grease does not conduct electricity but protects the metal terminals from moisture and corrosion, which is the number one killer of automotive electrical systems.

When splicing into the factory harness, use heat-shrink tubing rather than electrical tape. Electrical tape adhesive eventually fails due to engine heat, whereas heat-shrink provides a permanent, waterproof seal that reinforces the wire gauge at the joint.

When selecting replacement parts, prioritize high-heat ceramic sockets over standard plastic ones. Ceramic can withstand the high temperatures generated by modern halogen and LED bulbs without warping or melting. If you are performing a custom installation on an older vehicle, consider adding a dedicated headlight relay circuit. This allows the heavy current to travel directly from the battery to the bulbs, while your dashboard switch only handles a tiny amount of trigger current. This setup prevents voltage drop and protects your expensive interior switches from burning out.

- ✓ Verify Voltage: Ensure the bulb receives at least 12.6V while the engine is running for maximum brightness.

- ✓ Proper Grounding: Always ground to a structural metal component, not just a thin trim piece.

- ✓ Labeling: Use small tags to label your high beam traveler and low beam hot wires for future maintenance.

- ✓ Quality Sockets: Choose sockets with pre-tinned copper wire to prevent internal oxidation.

In conclusion, mastering the 3 prong headlight wiring diagram is a fundamental skill for any DIY mechanic or vehicle enthusiast. By understanding the relationship between the hot wire, the traveler wire, and the common terminal, you can ensure your vehicle’s lighting system is both powerful and reliable. Remember to always prioritize safety by checking your wire gauge and securing your connections against the elements. With the right tools and this guide, you can confidently maintain or upgrade your headlights for optimal visibility and safety.

Frequently Asked Questions

What is 3 prong headlight wiring diagram?

A 3 prong headlight wiring diagram is a visual schematic used to map out the electrical connections for dual-filament bulbs. It identifies the high beam, low beam, and ground paths. By following this layout, DIYers can ensure their vehicle lighting functions correctly without accidentally overloading the vehicle’s electrical system.

How do you read 3 prong headlight wiring diagram?

Reading this diagram requires identifying the three main terminals: power for high beam, power for low beam, and the ground. Symbols represent wires, connectors, and the battery source. Match the color-coded lines on the schematic to the physical wires in your vehicle’s harness for accurate pinout and terminal identification.

What are the parts of 3 prong headlight wiring?

The main parts include the bulb housing, the three-pin connector, the headlight switch, and the relay. Internally, the circuit utilizes a hot wire for power, a traveler wire for switching between beam intensities, and a ground wire to return current to the battery, ensuring consistent and safe lighting performance.

Why is ground wire important?

The ground wire is critical because it provides a return path for the electrical current. Without a solid ground connection, the headlight circuit remains open, meaning the bulbs will not illuminate. A loose or corroded ground often causes flickering, dim lights, or complete failure of the specific headlight beam system.

What is the difference between hot wire and neutral wire?

In automotive DC systems, the hot wire carries 12V positive current to the bulb, while the neutral wire concept is replaced by a ground connection. In standard AC lighting, a neutral wire carries current back to the source, whereas in cars, the metal chassis serves as the negative return.

How do I use 3 prong headlight wiring diagram?

Use the diagram to troubleshoot lighting failures or when upgrading to modern LED conversion kits. First, identify the common terminal and test for voltage at each pin using a multimeter. Follow the schematic to verify that each wire correctly reaches its intended destination on the relay or headlight switch.