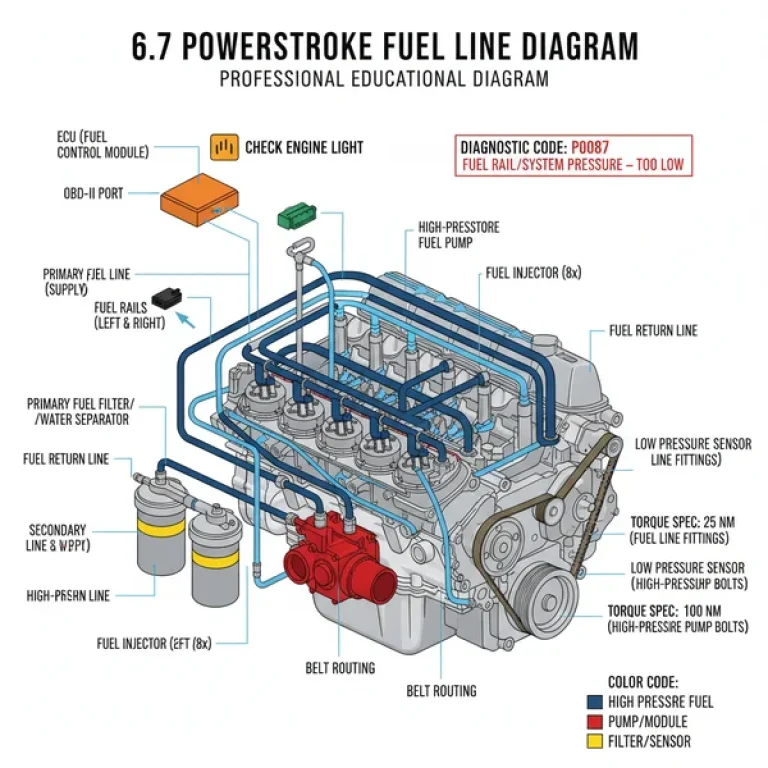

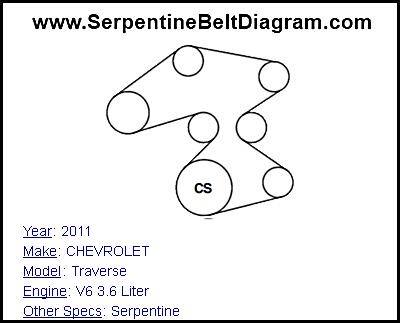

3.6 Liter Chevy Traverse Serpentine Belt Diagram: Routing Guide

The 3.6L Chevy Traverse serpentine belt diagram shows the belt wrapping around the crankshaft, alternator, water pump, and AC compressor. Tension is released using a 1/2-inch drive on the auto-tensioner. Proper routing prevents pulley damage and battery drainage, ensuring your alternator maintains power for the ECU and vehicle electronics.

📌 Key Takeaways

- Correct belt routing path across all six pulleys

- Automatic tensioner location on the lower passenger side

- Importance of clearing debris from pulley grooves

- Visual inspection points for worn or cracked ribs

- Using the diagram to verify alignment after water pump repair

Navigating the engine bay of a modern SUV can be daunting, but understanding the 3.6 liter 2011 chevy traverse 3.6 serpentine belt diagram is the first step toward successful DIY maintenance. Whether you are dealing with a persistent squeal or performing preventative maintenance, having a clear visual guide is essential for routing the belt correctly around various pulleys. This comprehensive guide provides the exact routing path, explains the function of each component, and offers professional-grade tips to ensure your vehicle remains reliable. You will learn the specific steps for replacement, the tools required, and how to identify signs of premature wear before they lead to a breakdown.

The 2011 Chevy Traverse uses a single long-length serpentine belt to power all major engine accessories. This belt is held in place by an automatic spring-loaded tensioner, meaning no manual adjustments are required once the belt is properly seated.

Understanding the 3.6 Serpentine Belt Layout

The 3.6L V6 engine (LLT engine code) in the 2011 Chevy Traverse utilizes a sophisticated accessory belt system designed to maximize space and efficiency. The diagram follows a complex “S” pattern to ensure maximum contact area, also known as “belt wrap,” on each pulley. This contact is vital for transferring the rotational energy from the crankshaft to the components that keep your car running.

The primary pulleys involved in this diagram include the crankshaft pulley (the large drive pulley at the bottom), the alternator (top rear), the power steering pump (top front), the air conditioning compressor (bottom front), and the water pump (center). Additionally, there is one stationary idler pulley and one spring-loaded tensioner pulley. The tensioner is located between the alternator and the crankshaft, acting as the gateway for installing or removing the belt.

In the diagram, the belt leaves the top of the crankshaft pulley and travels upward to the alternator. From the alternator, it wraps around the idler pulley, then moves toward the power steering pump. It then dives down to the water pump, loops over the A/C compressor, and finally returns to the crankshaft via the tensioner pulley. This specific sequence is critical; if the belt is routed incorrectly, the water pump might spin backward, leading to a total failure of coolant flow and subsequent engine overheating.

[DIAGRAM_PLACEHOLDER: A detailed technical illustration showing the 3.6L V6 engine front profile with a blue line representing the belt path, numbered pulleys 1-7, and arrows indicating the clockwise rotation of the crankshaft.]

Step-by-Step Replacement Guide

Replacing the accessory belt on a 2011 Traverse requires a bit of patience due to the tight clearance between the engine and the passenger-side inner fender well. Following these steps will help you navigate the process efficiently.

Required Tools and Materials

- ✓ 1/2-inch drive long-handle breaker bar or a serpentine belt tool

- ✓ 15mm socket (for the tensioner bolt)

- ✓ Flathead screwdriver or trim clip tool (to remove the splash shield)

- ✓ New high-quality serpentine belt (EPDM material recommended)

- ✓ Work light or flashlight

Installation Procedure

1. Preparation and Safety: Ensure the engine is completely cool to the touch. Park on a level surface, engage the parking brake, and disconnect the negative battery terminal. This prevents the ECU from attempting any cycles and ensures safety while working near moving parts.

2. Access the Belt: While some technicians work from the top, it is much easier to remove the front passenger-side wheel and the plastic inner fender splash shield. This provides a direct line of sight to the crankshaft and tensioner.

3. Document the Routing: Before removing the old belt, compare your physical engine to the 3.6 liter 2011 chevy traverse 3.6 serpentine belt diagram. Note how the “ribbed” side of the belt sits in the grooves of the pulleys, while the “smooth” side touches the smooth idler and tensioner pulleys.

4. Release Tension: Locate the 15mm bolt head on the center of the tensioner pulley. Fit your breaker bar or tool onto this bolt. Rotate the tensioner clockwise (toward the front of the vehicle) to compress the spring. This will create slack in the belt.

5. Remove the Belt: While holding the tensioner in the compressed position, slip the belt off the uppermost pulley (usually the power steering pump or alternator). Slowly release the tensioner and then thread the belt out from around the remaining pulleys.

6. Inspect the Pulleys: Spin each pulley by hand. They should spin smoothly without noise or “wobble.” If a pulley feels gritty or makes a metallic sound, the bearing is failing and should be replaced now.

7. Install the New Belt: Thread the new belt starting from the bottom. Follow the diagram precisely. The most common method is to route it around the crankshaft, A/C, water pump, and alternator first. Leave the smooth idler pulley or the power steering pump for last.

8. Final Seating: Once again, rotate the tensioner clockwise. Slide the last loop of the belt over the final pulley. Release the tensioner slowly. Double-check that every rib of the belt is perfectly centered in the pulley grooves. If the belt is even one “tooth” off, it will shred within minutes of starting the engine.

Use a small piece of chalk to mark the direction of rotation on the old belt if you plan on reusing it. However, if you have gone through the trouble of removing it, installing a new belt is the most cost-effective insurance against future breakdowns.

Common Issues & Troubleshooting

A failing serpentine belt system can trigger several symptoms that might initially seem unrelated. One of the most common signs is a high-pitched squealing noise, especially during cold starts or sharp turns. This usually indicates belt slippage or a tensioner that has lost its spring rate.

If the belt snaps or slips significantly, the alternator will stop charging the battery. This may cause the ECU to trigger a check engine light or a “Battery Not Charging” message on the dashboard. In some cases, a specific diagnostic code like P0621 (Generator Lamp Control Circuit) may appear. Furthermore, because the belt drives the water pump, a failure will immediately halt coolant flow. If you notice your temperature gauge rising rapidly, pull over immediately to prevent catastrophic engine damage.

Never attempt to change the belt while the engine is running or while the ignition is in the “On” position. Modern ECU systems can trigger fans or other components to move without warning.

Another issue specific to the 2011 Traverse is oil leaks from the front timing cover. If oil gets onto the serpentine belt, it will cause the rubber to swell and deteriorate rapidly. If you see a diagnostic code related to the OBD-II system for engine misfires or sensors, check to ensure that a failing belt hasn’t damaged any nearby wiring harnesses.

Maintenance Tips & Best Practices

To get the most mileage out of your 3.6 liter 2011 chevy traverse 3.6 serpentine belt diagram and the components it serves, regular inspections are key. Most modern EPDM belts do not crack like older neoprene belts; instead, they lose material in the grooves. Use a “belt wear gauge” to check the depth of the ribs every 30,000 miles.

When replacing the belt, it is often wise to replace the tensioner and idler pulley at the same time. These components have bearings that are rated for similar lifespans as the belt. Using a “kit” that includes the belt and both pulleys can save you from having to perform the labor a second time six months later. Also, ensure you adhere to the proper torque spec when tightening any pulley bolts you may have loosened.

While you have the belt off, take a moment to inspect the area for timing chain noise. The 3.6L LLT engine is known for timing chain stretch issues; with the accessory belt removed, you can briefly start the engine to see if a rhythmic ticking or rattling persists. This helps isolate whether a noise is coming from an accessory (like a bad A/C bearing) or the internal engine components.

Finally, always keep a copy of the routing diagram in your glove box. In an emergency roadside situation, having the 3.6 liter 2011 chevy traverse 3.6 serpentine belt diagram readily available can be the difference between a quick fix and an expensive tow. By following these professional guidelines and staying proactive with your maintenance, you ensure that your Traverse remains a reliable vehicle for years to come.

Frequently Asked Questions

What is a 3.6 Chevy Traverse serpentine belt diagram?

A 3.6 Chevy Traverse serpentine belt diagram is a visual schematic illustrating the precise path the drive belt takes around various engine pulleys. It identifies the locations of the alternator, water pump, and air conditioning compressor. Following this map is essential during maintenance to ensure all engine accessories function properly without slipping.

How do you read a serpentine belt diagram?

Reading the diagram requires following the continuous line representing the belt as it loops over and under specific pulleys. Smooth pulleys usually contact the back of the belt, while ribbed pulleys grip the inner side. Start at the large crankshaft pulley and trace the path clockwise to ensure correct installation.

What are the parts of the 3.6L accessory drive?

The main components include the crankshaft balancer, alternator, water pump, power steering pump, and A/C compressor. Additionally, the system features an idler pulley and an automatic tensioner assembly. Each part must be aligned perfectly with the belt ribs to avoid generating a diagnostic code or causing premature belt wear.

Why is the belt tensioner important?

The tensioner is critical because it maintains constant pressure on the belt, preventing slippage. If the tensioner fails, the alternator may stop charging, causing the ECU to trigger a check engine light. Ensuring the tensioner moves freely and applying the correct torque spec to its mounting bolt is vital for engine reliability.

What is the difference between a belt squeal and a pulley failure?

Belt squeal is often caused by a stretched belt or moisture, while pulley failure involves mechanical bearing noise. If a pulley seizes, it can throw the belt and result in an OBD-II error related to system voltage. Diagrams help identify which specific pulley might be misaligned or failing during inspection.

How do I use the serpentine belt diagram?

Use the diagram as a reference before removing the old belt. Note the orientation of the belt around the tensioner and idler pulleys. Once the new belt is positioned, double-check the diagram to ensure it sits deep in the grooves of every ribbed pulley before starting the engine to test performance.