2012 Chevy Traverse Belt Diagram: Routing & Installation

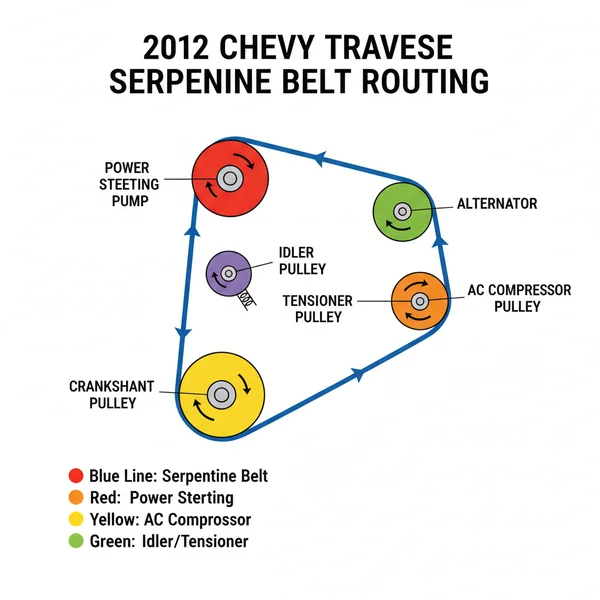

The 2012 Chevy Traverse serpentine belt diagram illustrates the precise path the belt takes around the engine pulleys. It coordinates the alternator, power steering pump, and water pump within the drive system. Understanding this configuration is vital for maintaining the engine’s auxiliary functions and ensuring the tensioner provides correct pressure.

📌 Key Takeaways

- Provides the exact visual path for the serpentine belt routing

- The automatic tensioner is the most critical component for belt removal

- Ensure the engine is off and the battery is disconnected for safety

- Take a digital photo of the existing belt layout before removal

- Essential for DIY belt replacement or troubleshooting engine squeaks

Navigating the engine bay of a modern crossover can feel like a daunting task, especially when you are faced with the intricate web of a serpentine belt system. If you are looking for a clear and accurate 2012 chevy traverse belt diagram, you have come to the right place. This comprehensive guide is designed to help you understand the specific routing path, identify the various pulleys involved, and provide a roadmap for successful maintenance. Whether you are dealing with a persistent squeal or performing preventative maintenance, having a visual reference of the belt’s configuration is essential for any DIY enthusiast. In the following sections, you will learn how to interpret the layout, the tools required for a replacement, and the common pitfalls to avoid during the installation process.

The 2012 Chevrolet Traverse is equipped with a 3.6L V6 engine that utilizes a single serpentine belt to power multiple peripheral components. This “all-in-one” design means that if the belt fails, you lose power steering, alternator charging, and air conditioning simultaneously.

Understanding the 3.6L V6 Belt System Structure

The 2012 Chevy Traverse relies on a sophisticated serpentine belt system to transfer rotational energy from the engine’s crankshaft to several critical accessories. The belt itself is a long, continuous loop made of durable rubber compounds, featuring a ribbed side and a smooth side. Understanding the structure of this system begins with identifying the primary components that the belt interacts with. In the 3.6L V6 engine layout, the belt follows a complex, multi-point path that ensures maximum surface contact with each pulley to prevent slippage.

The primary driver of the system is the Crankshaft Pulley, located at the bottom of the engine block. From there, the belt travels upward to the Alternator, which provides electrical power to the vehicle. It then routes around the Water Pump, which is vital for engine cooling, and the Power Steering Pump, which assists in maneuvering the vehicle. The Air Conditioning (A/C) Compressor is also part of this loop, typically positioned lower in the engine bay. To maintain the necessary tension and direction, the system incorporates an Idler Pulley and an Automatic Tensioner Pulley. The tensioner is a spring-loaded component that keeps the belt tight as it stretches over time.

Visually, the 2012 chevy traverse belt diagram shows the belt weaving in an “S” or serpentine pattern. The ribbed side of the belt always makes contact with pulleys that have matching grooves (like the alternator and crankshaft), while the smooth side of the belt usually runs against smooth pulleys, such as the idler or the tensioner. This distinction is crucial because improper routing—specifically placing the smooth side on a grooved pulley—will lead to rapid belt failure and potential engine damage.

While the basic configuration remains consistent for the 2012 model year, it is important to note that the layout is specifically designed for the transverse engine mounting. Because the engine is mounted sideways, the belt system is located on the passenger side of the vehicle, tucked tightly against the inner fender well. This specific layout means that visibility is limited, making the diagram an indispensable tool for anyone attempting a repair or inspection.

Step-by-Step Guide to Interpreting and Installing the Belt

Reading the 2012 chevy traverse belt diagram is the first step, but executing the physical work requires a systematic approach. Due to the cramped quarters of the Traverse engine bay, patience and the right tools are your best assets. Before you begin, ensure you have a long-reach serpentine belt tool or a 1/2-inch drive breaker bar, as a standard socket wrench often lacks the clearance needed to reach the tensioner.

Before removing the old belt, take a photo of the routing on your phone. Even with a diagram, a real-world visual reference of your specific engine can prevent confusion during the re-installation phase.

- ✓ Step 1: Preparation and Safety – Park the vehicle on a level surface and engage the parking brake. Disconnect the negative battery terminal to prevent any accidental engine starts. Since the belt is located on the passenger side, you will likely need to remove the front passenger wheel and the plastic interior splash shield (fender liner) to gain full access to the crankshaft and tensioner pulleys.

- ✓ Step 2: Locate the Tensioner – Identify the automatic tensioner pulley. On the 2012 Traverse, the tensioner has a square hole or a bolt head specifically designed for a tool to leverage against. It is usually located in the middle-right section of the belt’s path when viewed from the side.

- ✓ Step 3: Release Tension – Insert your serpentine belt tool or breaker bar into the tensioner. Rotate the tool (usually clockwise) to compress the internal spring and release the tension on the belt. While holding the tool in this position, carefully slip the belt off the uppermost pulley, which is typically the alternator or an idler pulley.

- ✓ Step 4: Remove the Old Belt – Once the tension is released, you can feed the belt through the narrow gaps between the engine and the frame. Inspect the old belt for signs of uneven wear, which could indicate a misaligned pulley rather than just a worn-out belt.

- ✓ Step 5: Clean the Pulleys – Before installing the new belt, use a wire brush or a clean rag to remove any rubber debris or oil from the pulley grooves. A clean surface ensures better grip and longer belt life.

- ✓ Step 6: Route the New Belt – Following your 2012 chevy traverse belt diagram, begin threading the new belt. It is often easiest to start at the bottom with the crankshaft and A/C compressor, working your way up. Leave the smooth idler pulley or the alternator for the final step.

- ✓ Step 7: Final Tensioning – Again, use your tool to rotate the tensioner. Slip the final loop of the belt over the remaining pulley. Slowly release the tensioner, allowing it to apply pressure to the belt.

- ✓ Step 8: Inspection – Double-check that the belt’s ribs are perfectly seated within the grooves of every pulley. If the belt is even one rib off, it will shred within minutes of starting the engine. Replace the fender liner and wheel before reconnecting the battery.

Never place your fingers between the belt and the pulley while the tensioner is engaged or while you are moving the tensioner. The spring force is strong enough to cause serious injury if the tool slips.

Common Issues & Troubleshooting

A failing serpentine belt system in a 2012 Chevy Traverse often manifests through specific audible and visual cues. The most common complaint is a high-pitched squealing or chirping noise, especially during cold starts or sharp turns. This typically indicates that the belt has lost its elasticity or that the tensioner is no longer providing sufficient pressure. By referencing the 2012 chevy traverse belt diagram, you can pinpoint which component might be causing the noise. For instance, if the squeal happens only when the air conditioning is on, the A/C compressor pulley or the belt’s grip on it may be the culprit.

Another frequent issue is “belt jump,” where the belt partially or completely slips off the pulleys. This is often caused by a failing idler pulley bearing or a misaligned tensioner. If you notice the belt fraying at the edges, this is a clear sign of a component misalignment within the system layout. Furthermore, look for “glazing” on the smooth side of the belt, which looks like a shiny, burnt surface. This happens when the belt slips and creates excessive heat. If you experience a sudden loss of power steering or your battery light illuminates on the dashboard, the belt has likely snapped or slipped entirely. In such cases, pull over immediately to prevent engine overheating, as the water pump will no longer be circulating coolant.

Tips & Best Practices for Belt Maintenance

Maintaining the belt system in your Traverse doesn’t have to be a reactive process. By following a few professional best practices, you can extend the life of your engine components and avoid being stranded on the side of the road. First and foremost, always choose high-quality EPDM (Ethylene Propylene Diene Monomer) belts. Unlike older neoprene belts, EPDM does not typically crack with age; instead, the grooves wear down much like the tread on a tire. You should use a belt wear gauge tool to check the depth of the grooves every 60,000 miles.

When replacing the belt, it is highly recommended to replace the tensioner and the idler pulley at the same time. These components have bearings that wear at a similar rate to the belt. Installing a brand-new, stiff belt on a worn tensioner often causes the tensioner to fail shortly after.

Another cost-saving tip is to inspect the pulleys for any fluid leaks. The 3.6L engine in the 2012 Traverse is known for occasional power steering pump or front main seal leaks. If oil or hydraulic fluid gets onto the belt, it will cause the rubber to swell and fail prematurely. Keeping the engine clean and addressing leaks early will save you from multiple belt replacements. Finally, always keep a copy of the 2012 chevy traverse belt diagram in your glove box. In an emergency, having that layout readily available can make a stressful roadside repair much more manageable. By staying proactive and understanding the configuration of your vehicle’s belt system, you ensure the long-term reliability of your Chevy Traverse.

Frequently Asked Questions

What is 2012 chevy traverse belt diagram?

It is a visual representation of the serpentine belt routing system for the 3.6L V6 engine. This layout displays how the belt wraps around various pulleys, including the crankshaft, alternator, and air conditioning compressor, ensuring all components receive power from the engine’s rotation effectively and reliably.

How do you read 2012 chevy traverse belt diagram?

You read the diagram by identifying the smooth and grooved pulleys within the engine configuration. Lines representing the belt will show whether the ribbed side or the flat side contacts a specific component. Follow the arrows to understand the rotational direction and the sequence of routing for the belt.

What are the parts of 2012 chevy traverse belt?

The system consists of the drive belt, the crankshaft pulley, alternator, power steering pump, water pump, and A/C compressor. It also includes an idler pulley and a spring-loaded tensioner, which is a critical component for maintaining the correct pressure across the entire belt structure during engine operation.

Why is the tensioner component important?

The tensioner is a vital component because it maintains constant pressure on the belt to prevent slippage. Without proper tension, the serpentine system cannot drive the alternator or water pump efficiently, leading to battery drain, engine overheating, or a total loss of power steering assistance while driving.

What is the difference between an idler and a tensioner?

An idler pulley is a fixed component that helps guide the belt path or provides additional wrap around other pulleys. In contrast, the tensioner is a dynamic part of the system that uses a spring mechanism to automatically adjust and maintain the necessary tightness of the belt configuration.

How do I use 2012 chevy traverse belt diagram?

Use the diagram as a blueprint during a belt replacement procedure. By following the specific layout, you can thread the new belt around the correct pulleys in the right order. This ensures the system functions correctly and prevents damage to the engine components caused by improper routing or installation.