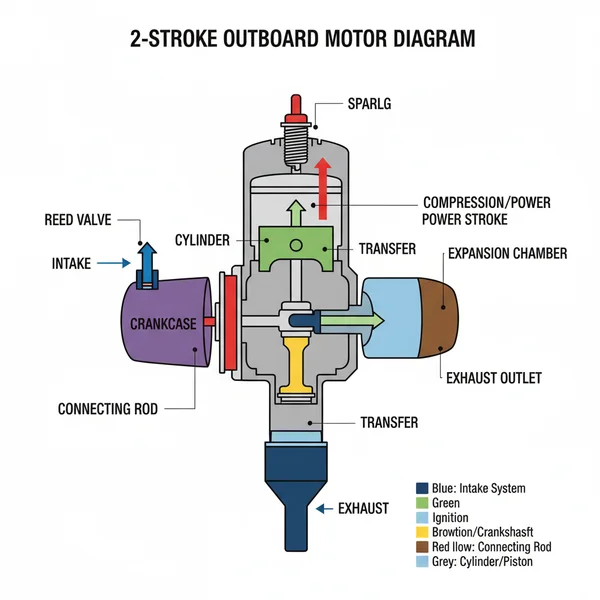

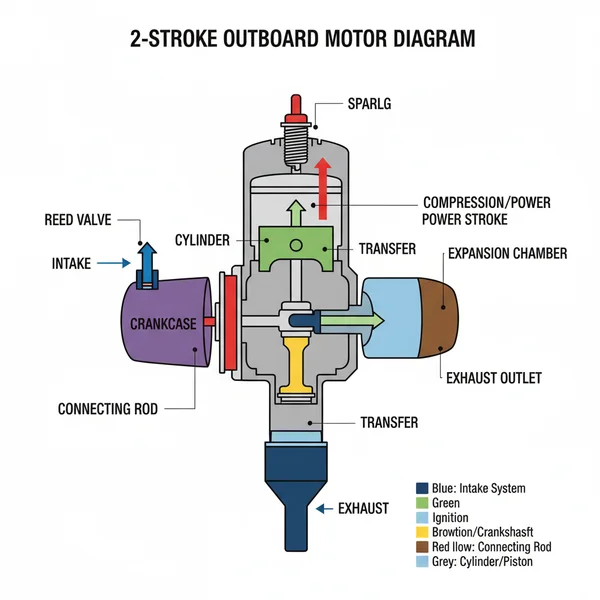

A 2 stroke outboard motor diagram illustrates the engine’s internal structure, showing how the piston, crankshaft, and intake/exhaust ports function within a two-phase cycle. By visualizing the layout, users can identify the fuel-oil mixing system and cooling passages, essential for maintaining proper engine configuration and ensuring reliable marine performance.

📌 Key Takeaways

- Visualizes the internal combustion cycle of the engine

- Identifies the reed valve and transfer ports as critical components

- Highlights the importance of the fuel-to-oil mixture ratio

- Assists in identifying parts for winterization or repair

- Use during routine maintenance or part replacement tasks

Whether you are a seasoned boat owner or a newcomer to marine mechanics, understanding a 2 stroke outboard motor diagram is the first step toward successful maintenance and repair. These engines are prized for their power-to-weight ratio and simplicity, yet their internal workings require precision. Having a clear visual map allows you to identify critical components, understand the layout of the cooling system, and troubleshoot ignition issues without guesswork. In this guide, you will learn how to interpret a standard 2 stroke outboard motor diagram, identifying the core structure that drives your vessel across the water.

Understanding the Layout and Component Structure

A 2 stroke outboard motor diagram typically breaks the engine down into three primary sections: the powerhead, the midsection, and the lower unit. Unlike four-stroke engines, which use a complex valve train, the two-stroke configuration relies on ports within the cylinder wall to manage the intake and exhaust cycles. The diagram illustrates how the crankshaft, connecting rods, and pistons are positioned within the crankcase to facilitate this unique combustion process.

In a two-stroke system, the crankcase is part of the induction system. This means the fuel-oil mixture passes through the crankcase to lubricate moving parts before entering the combustion chamber.

At the top of the diagram, you will find the flywheel and the ignition system. The layout shows the stator located beneath the flywheel, which generates the electrical charge needed for the spark plugs. Moving downward, the diagram details the fuel system, including the carburetor or fuel injectors and the reed valve assembly. The reed valves act as one-way check valves, ensuring the fuel-air mixture enters the crankcase but does not blow back out during the piston’s downward stroke.

The midsection of the diagram displays the exhaust housing and the swivel bracket, which allows the motor to tilt and turn. Finally, the lower unit, or gearcase, contains the water pump impeller, the drive shaft, the shift mechanism, and the propeller shaft. Color-coding in high-quality diagrams often uses blue for the cooling water flow, red for high-voltage electrical paths, and green or yellow for fuel lines to help the user distinguish between overlapping systems.

Step-by-Step Guide to Interpreting the Diagram

Reading a 2 stroke outboard motor diagram can feel overwhelming at first glance due to the density of lines and labels. However, by following a systematic approach, you can use these schematics to perform complex tasks like rebuilding a carburetor or replacing a water pump impeller.

Step 1: Orient the Perspective

Most diagrams offer either a “profile view” (side) or an “exploded view.” The profile view is best for understanding the general system configuration and how components interact spatially. The exploded view is essential for assembly and disassembly, as it shows every bolt, washer, and gasket in the order they are installed. Determine which view you are looking at before proceeding with any mechanical work.

Step 2: Trace the Fuel Path

Locate the fuel inlet on your diagram. Follow the line from the fuel pump to the carburetor (or fuel rail in injected models). Notice the path through the reed valves and into the cylinder. Understanding this layout is crucial if your engine is bogging down or failing to start, as it helps you identify potential clogs or air leaks in the system.

Step 3: Analyze the Cooling System

Locate the water intake grates on the lower unit of the diagram. Follow the path upward through the water pump, up the copper water tube, and into the cooling jackets surrounding the cylinders. The diagram will show the thermostat’s location—usually at the highest point of the powerhead—and the “tell-tale” outlet where water exits the motor to indicate the pump is working.

Never run a 2 stroke outboard motor without a water supply (flushing muffs or a test tank). The diagram shows the impeller is made of rubber; without water for lubrication and cooling, it will disintegrate in seconds.

Step 4: Identify Ignition and Electrical Layout

Look for the spark plugs and trace the wires back to the ignition coils and the CDI (Capacitor Discharge Ignition) box. The diagram will often include a wiring color code key. This is vital for testing electrical resistance or replacing a faulty kill switch. If you have no spark, the diagram helps you locate the ground points that might be corroded.

Step 5: Inspect the Lower Unit Configuration

Focus on the bottom of the schematic to see the gear layout. You will see the pinion gear, the forward gear, and the reverse gear. Understanding this layout is necessary when the motor won’t shift correctly or if you hear grinding. The diagram illustrates how the shift rod moves the dog clutch to engage different gears.

Step 6: Confirm Torque and Fastener Specifications

While the diagram shows where parts go, many technical layouts also provide torque specifications for critical bolts like the cylinder head or the flywheel nut. Ensure you have a torque wrench and the correct marine-grade lubricants (such as 2-4-C grease or anti-seize) as indicated by the diagram’s notes before beginning a rebuild.

Common Issues and Troubleshooting with a Diagram

A 2 stroke outboard motor diagram serves as your primary diagnostic tool when performance drops. One of the most frequent issues is a “no-start” condition. By referencing the diagram, you can systematically check the “Big Three”: fuel, spark, and compression. If the spark is missing, the diagram allows you to locate the stator and trigger coils to test their output with a multimeter.

Overheating is another common problem. If your motor is running hot, use the diagram to trace the cooling path. It will point you to the thermostat and the pressure relief valve (poppet valve). Often, salt or sand can clog these specific areas, and the diagram shows exactly which covers to remove to clear the debris. Additionally, if you see “milky” oil in the lower unit, the diagram helps you identify the location of the prop shaft seals and the O-rings that need replacement to prevent water intrusion.

If you are troubleshooting an intermittent stall, use the diagram to find the crankcase seals. On an older 2 stroke, a leaking top or bottom seal can cause air to enter, leaning out the mixture and causing erratic idling.

Maintenance Tips and Best Practices

To keep your motor running as smoothly as the day it was manufactured, regular maintenance is mandatory. Using your 2 stroke outboard motor diagram as a checklist ensures that no component is overlooked during your annual service. Two-stroke engines are particularly sensitive to fuel quality and lubrication, so focusing on these areas will save you significant money in the long run.

- ✓ Use Fresh Fuel and High-Quality Oil: Always use the fuel-to-oil ratio specified on your motor’s data plate or diagram (common ratios are 50:1 or 100:1). Use TC-W3 rated oil to prevent carbon buildup in the ports.

- ✓ Inspect Reed Valves: Every few seasons, check the reed valves shown in your diagram. Frayed or chipped reeds will lead to poor starting and reduced top-end power.

- ✓ Change Lower Unit Gear Lube: Refer to the diagram to locate the “Fill” and “Vent” screws on the gearcase. Change this oil at least once a year to protect the expensive gears inside.

- ✓ Decarbonize the Engine: Two-strokes are prone to carbon “coking” around the piston rings. Periodically use a specialized marine carbon cleaner to keep the ports clear as shown in the internal cylinder layout.

- ✓ Replace the Impeller: The water pump impeller is a wear item. Even if the motor isn’t overheating, the rubber becomes brittle over time. Replace it every 2-3 years using the lower unit diagram for guidance.

In conclusion, mastering the 2 stroke outboard motor diagram is about more than just knowing where parts are located; it is about understanding the synergy of the entire system. From the way the fuel enters the crankcase to the way the exhaust exits through the propeller hub, every component has a specific role in the motor’s layout. By keeping a copy of the correct diagram for your specific model on hand, you empower yourself to perform your own repairs, ensure your safety on the water, and extend the lifespan of your engine for years of reliable boating. When in doubt, always refer back to your specific manufacturer’s configuration to ensure the highest degree of accuracy.

Frequently Asked Questions

What is 2 stroke outboard motor diagram?

A 2 stroke outboard motor diagram is a visual schematic that illustrates the internal component layout and mechanical structure of a marine engine. It details how the engine completes a power cycle in just two piston strokes, showing the relationship between the fuel system, ignition, and cooling.

How do you read 2 stroke outboard motor diagram?

To read this diagram, start by identifying the main powerhead configuration at the top and follow the flow from the intake ports to the combustion chamber. Look for labels indicating the crankshaft, connecting rod, and exhaust system to understand how power is transferred to the lower unit.

What are the parts of 2 stroke outboard motor?

The primary parts shown in the diagram include the cylinder head, piston, crankshaft, and spark plug. Additionally, it highlights the reed valves, carburetor, transfer ports, and the cooling water jacket, which are essential for the engine’s compact and high-power-to-weight ratio system during operation.

Why is the reed valve important?

The reed valve is a crucial component because it acts as a one-way check valve for the fuel-air mixture. It ensures that the intake charge enters the crankcase but cannot escape during the downward piston stroke, maintaining the necessary pressure for efficient engine configuration and performance.

What is the difference between 2 stroke and 4 stroke?

The main difference lies in the cycle frequency and lubrication system. A 2 stroke engine completes power cycles more frequently and mixes oil with fuel, while a 4 stroke has separate oil reservoirs and valves. The 2 stroke layout is generally simpler, lighter, and contains fewer moving parts.

How do I use 2 stroke outboard motor diagram?

Use this diagram to troubleshoot starting issues or performance drops by locating specific components like the ignition coil or fuel pump. It serves as a blueprint for disassembly and reassembly, ensuring every part of the engine structure is correctly aligned during maintenance or deep cleaning procedures.